Materials of which single unit size is in between 1 to 1000 nanometers but usually is 1 to 100 nm are termed as the nanomaterials. Carbon Nanotubes ( a form of carbon allotrope) has been emerged as an amazing material of the 21st century and attracted tremendous research interest due to its very exceptional properties. Still, rigorous research is being carried out on CNTs and CNTs based composites in almost all the spheres of science and engineering.

History of carbon nanotubes

History of CNTs is perhaps as fascinating as the nanotubes themselves. In actuality, carbon nanotubes had been discovered 30 years earlier but had not been fully appreciated at that time.

Year | Scientist | Discovery |

Late 1950s | Roger Bacon | A straight & hollow tubes of graphitic carbon layers. |

In 1970s | Morinobu Endo | Single-layer tubes of rolled-up graphite. |

In 1991 | Sumio Iijima | Multi-wall carbon nanotubes in a carbon arc discharge. |

In 1993 | Iijima and Bethune | Single-wall nanotubes (Buckytubes). |

Structure of Carbon Nanotubes

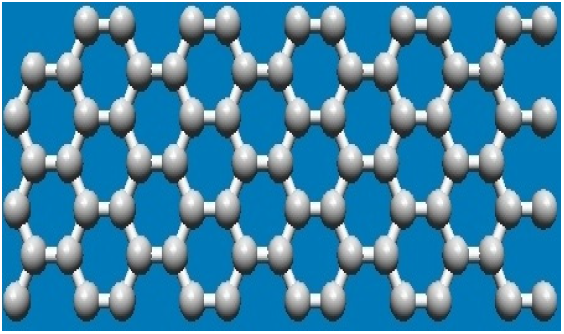

Carbon nanotubes are cylindrical molecules that consist of a rolled-up sheet of graphene while graphene is a 2 D monoatomic hexagonal lattice of a carbon allotrope. They are the basic structural element of other allotropes including graphite charcoal carbon nanotubes and fullerenes.

Classification of Carbon nanotubes:

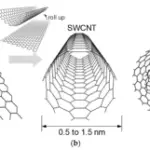

Carbon nanotubes can be in a variety of forms based on the no of constituent graphene layers. If carbon nanotubes consist of a single layer of graphene, it is called single-wall carbon nanotubes, SWCNTs while multiple sheets of graphene form the multi-walled carbon nanotubes MWCNTs.

Single-walled Carbon Nanotubes, SWCNTs:

SWCNTs are made of a single graphene sheet that is rolled into a cylindrical shape.

| Forming SWCNTs from a single Graphene sheet |

Double-walled Carbon Nanotubes, DWCNTs:

In this structure exactly two coaxial concentric graphene layers are wrapped inside each other.

| Forming DWCNTs from 2 Graphene sheets |

Triple walled Carbon Nanotubes, TWCNTs:

This structure is the next step in approaching MWCNTs and is characterized by the presence of three concentric layers of graphene sheets.

| Forming TWCNTs from 3 Graphene sheets |

Multi-walled Carbon Nanotubes MWCNTs:

Multi-walled carbon nanotubes, MWCNTs consist of multiple rolled layers of graphene.

| Forming MWCNTs from several Graphene sheets |

Carbon Allotropes:

Structural Features of Carbon Allotropes:

Isomer | Fullerene(C60) | Nanotube | Graphite | Diamond |

Dimension | 0D | 1D | 2D | 3D |

Bond shape | sp2 | sp2 | sp2 | sp3 |

Density (g/cm3) | 1.72 | 1.2-2.0 | 2.26 | 3.515 |

Bond length (nm) | 1.40 (C=C) | 1.44 (C=C) | 1.42 (C=C) | 1.54 (C-C) |

Electronic Properties | Semi-conductor | Metal or Semi-conductor | Semi-metal | Insulator |

Synthesis of CNTs:

| Arc Discharge Method |

| Laser Ablation Method |

| Chemical Vapour Deposition Method |

Miscellaneous Synthesis Methods:

CNTs can be synthesized by-

👉Ball milling,

👉Flame synthesis,

👉SiC decomposition,

👉Graphene scrolling Dipping hot graphite in cold water.

Merits-Demerits of CNTs Synthesis Methods:

Method | Arc Discharge | Chemical Vapor Deposition | Laser Ablation |

Merits | -Can easily produce SWNT, MWNTs. -SWNTs have few structural defects; -MWNTs without catalyst, -not too expensive, -open-air synthesis possible | -Easiest to scale up to industrial production; -long length, -simple process, -SWNT diameter controllable, -quite pure | -Primarily SWNTs, with good diameter control and few defects. -The reaction product is quite pure. |

Demerits | -Tubes tend to be short with random sizes and directions; -Often needs a lot of purification. | -CNTs are usually MWNTs and often riddled with defects | -The costly technique, because it requires expensive lasers and high power requirement, but is improving |

Typical defects in an SWCNTs:

👉(A) Five or seven-membered rings in the carbon framework instead of the normal six-membered ring leads to a bend in the tube.

👉(B) sp3 hybridized defects (R=H and OH).

👉(C) Carbon framework damaged by oxidative conditions, which leaves a hole lined with COOH groups.

👉(D) Open-end of the SWNT terminated with COOH groups.

👉(D) Open-end of the SWNT terminated with COOH groups.

Purification:

Determining the purity degree of nanotube material is still controversial as no unified standard has been established yet. SWCNTs purification usually employs various-

👉Oxidation steps,

👉Thermal treatments,

👉Sonication treatments,

👉Chemical Acid treatments.

Properties of Carbon Nanotubes (CNTs):

1. Mechanical Properties

👉Strong Like Steel

👉Light Like Aluminum

👉Elastic Like Plastic

2. Thermal Properties

👉High thermal conductivity ~2000W/m/K.

👉Very good thermal conductors along the tube.

👉The temperature stability is up to 2800℃ in a vacuum and about 750℃ in air.

3. Optical Properties

👉Stronger Raman signal.

👉Every nanotube –colourful.

👉Bulk nanotube samples –black.

👉Inelastic scattering of monochromatic light.

👉Nanotube absorbs light & show infrared luminescence.

4. Electrical Properties

👉Exhibit both metallic and semiconducting behaviour.

– Armchair structured CNTs show metallic properties.

– Chiral structured CNTs show semiconducting properties.

👉Very high current carrying capacity.

– Metallic CNTs can carry an electrical current density of 4×10^9A/cm^2 which is almost than 1,000 times greater than metals such as copper.

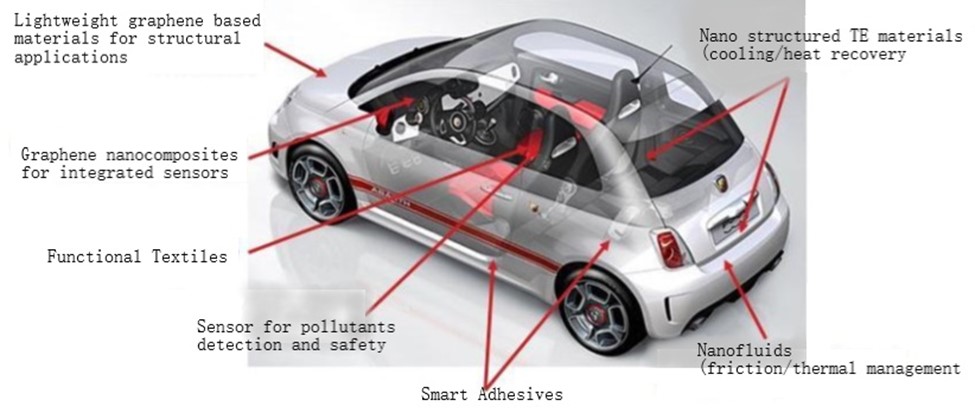

Applications of Carbon Nanotubes (CNTs):

👉Current Applications of Carbon Nanotubes

– Lithium Batteries.

– Anti-static Packaging.

– Structural Reinforcement.

– Enhance Fiber Composites.

– Electrically Conductive Fillers in Plastics.

– Bulk Composite Materials and Thin Films.

– Control or enhance conductivity in polymers.

– Sporting Goods like tennis rackets, baseball bats, and bicycle frames.

👉Potential Applications of CNTs

– Weight-sensitive applications such as kevlar.

– Semiconducting Properties: replace existing computer chips.

– Electrically Conductive: cost-effective replacement for metal wires.

– Environmentally-friendly, flame-retardant additive to plastics and paints.

Texpedi.com

Check out these related articles:

1 thought on “An Overview on Carbon Nanotubes”