Sonali Bag is the best replacement and recognized as the inception of new era of green packaging. Every year, we use a staggering 5 trillion plastic bags! 160,000 times per second! And over 700 per individual per year. A single plastic bag might take up to 1,000 years to decompose whereas plastic shopping bags are only used for 12 minutes on average. In a nutshell, we’ve polluted the environment for 1000 years in just 12 minutes.

we can observe the quantity of plastic bags produced each second in real time. Approximately 10% of this plastic ends up in the ocean. According to estimates, 300 million plastic bags wind up in the Atlantic Ocean alone each year. As a result, by 2050, the world’s oceans may contain more plastic than fish based on weight. Several times, various biodegradable and environmentally friendly bags have been launched over the world, however they have not persisted due to valuation.

This time Bangladeshi scientist Dr. Mubarak Ahmad Khan, presently working as scientific advisor of Bangladesh Jute Mills Corporation (BJMC) and former Chief Scientific Officer of Bangladesh Atomic Energy Commission invented a biodegradable and eco-friendly bag from jute cellulose named ‘Sonali Bag’ which is being considered as a great achievement for Bangladesh.

Here reporting about ‘Sonali Bag’ from new product development process point of view.

Idea Generation

Polythene that is not biodegradable is a global issue. Polythene is one of the most popular materials for packing and transporting goods. Given the long-term consequences of using polythene, its use should be curtailed in favor of environmentally suitable bags. The idea of biodegradable polythene originated here.

Idea screening

Let’s begin by filtering the concept through some examination. According to a SWOT analysis, Bangladesh’s strengths in creating ‘Sonali Bag’ are significant. With government assistance and continuous research for varied products and bio-plastics, Bangladesh is the world’s second largest producer of jute, with 1.349 million tons produced. Bangladesh ranks among the top jute-producing and exporting nations in the world. There are various flaws, such as a lack of infrastructure development and a less competent marketer, which make it difficult to compete with the traditional plastic business on the international market. Bangladesh, on the other hand, has numerous prospects and opportunities.

The conventional plastic sector poses the greatest danger because of its convenience, user friendliness, low cost, and appeal. The

Bangladesh jute industry will benefit greatly in the future by investing in bio-plastic polybags and growing demand. Bangladesh might use this chance to address infrastructure deficiencies and increase research funding. More focus on research and development, as well as a methodical approach to training, execution, and marketing, will help to mitigate weaknesses and avoid hazards.

Concept testing

Every new product in development should undergo concept testing. It specifies the customer’s acceptance of the product prior to its full commercialization. Due to global standards, it is believed that the usage of biodegradable packaging is required. The ‘Sonali Bag’ will function as a non-harmful polybag, with a price that is comparable to that of a traditional harmful non-degradable polybag. Dr. Mubarak Ahmed Khan, the inventor, believes that once mass production begins, the price will be affordable to the general public.

Business Analysis

As many prior inventions failed to succeed in the market due to exorbitant prices, keeping the price of this ‘Sonali Bag’ affordable for the general public is a major difficulty. From the source of Grand View Research, Energy and Gold Ltd. presented an interesting analysis on worldwide bio-industry growth. They stated that the bio-plastic market is predicted to increase at a 30% CAGR from 2013 to 2030, while the traditional plastic sector is expected to grow at a 3% annual rate. So, from a business standpoint, if it can successfully replace traditional plastic and polythene, it will be one of the major business industries.

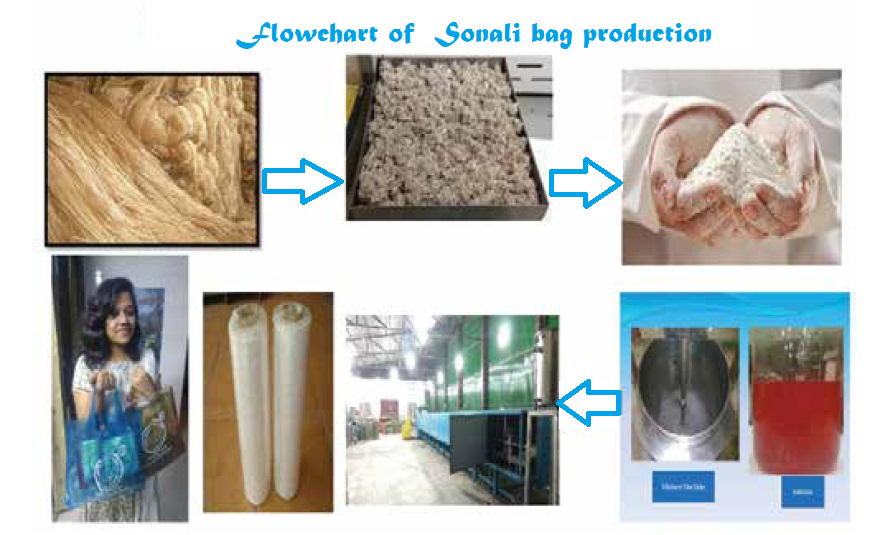

Product Development

Structurally, the

jute is composed of complex polymers consisting mainly of cellulose 75%, hemicelluloses 15% and lignin 10%. Besides, because of the small amount of fat, wax, nitrogenous matter, beta-carotene and xanthophylls, jute is deciduous and environment friendly.

To begin, cellulose is extracted from waste jute fibers that are discarded by jute mills. These cellulose fibers are insoluble in water, are then changed using chemical compounds. Soluble cellulose is combined with cross-linkers. The chemical reaction takes place at a specific temperature within a drawer machine. It comes out of the machine as plastic sheets as it dries. After that, the sheet is cut into a polybag shape. One kilogram of jute can be converted into one kilogram of polythene. The bag is fully lasting roughly five hours in water before gently melting. It promotes soil fertility by thoroughly mixing within 5-6 months as there are no dangerous additives. It seems to be a standard polythene bag, yet it is 1.5 times more durable and stronger than standard polyethylene bags.

Test Marketing

Bio-degradable products have a huge demand in global market. For example, EU imports 15% of world

jute products that mostly export from Bangladesh. Already the Melbourne City Council authorities in Australia have expressed interest in buying the bag to keep the city polythene-free and a US-based business firm in Dubai has placed order to buy 25,000 pieces of polybags a month. On October 2019, a memorandum of understanding (MoU) and an NDA were signed with a UK company for commercial production of Sonali Bags from Jute. Recently, countries in the world, including Italy, Brazil, Bhutan, China, Kenya, Rwanda, Somalia, Taiwan, Tanzania, Australia, the United States and the United Kingdom, have started reducing use of environmental harmful elements, including synthetic polybags.

Commercialization

Trade name ‘Sonali Bag’ is given by the PM Sheikh Hasina. It is not only for replacing the plastic bag, it has a huge world market possibility. BJMC took initiatives for piloting production, besides BJMC is going for an acquisition of 78 acres land in Norshingdi where the daily production will be 3-4 tons of bags. The ‘Sonali Bag’ project was allocated 10 crore tk from Bangladesh Climate Change Trust Fund by the government. But the amount was for purchasing chemicals and machineries. This waterproof polybag costs from BD Taka 250 to 300 per kg. But if the bag is manufactured and marketed commercially, the price will be further reduced. For commercialization, at least 400 crore taka is needed to be invested for this project according to Dr. Mubarak Ahmad Khan.

Monitoring and Evaluation

The ‘Sonali Bag’ project had successfully completed and already pilot run is executed. But for proper management and lack of funding still could not move to bulk preparation. The market is too ready on fire to grab the opportunity and needs step into the market before anyone else has the first bite of the apple.

Reference:

- https://www.theworldcounts.com/challenges/planet-earth/waste/plastic-bags-used-per-year/story

- SONALI BAG from Jute | Best Polythene Alternative | Made in Bangladesh

- https://www.textiletoday.com.bd

- https://www.researchgate.net

- https://enSonali Bag Brochure

Author:

Israt Zahan Mim

Bangladesh University of Textiles

Texpedi.com

Check out these related articles: