Carbon nanotubes have emerged as a revolutionary material with a wide range of applications, and the world of textiles is no exception to their transformative potential. These remarkable nanoscale cylinders, composed of rolled-up sheets of carbon atoms, are renowned for their extraordinary electrical conductivity, mechanical strength, and flexibility. When harnessed for textile applications, they introduce a new dimension of functionality, promising to reshape the landscape of smart textiles and wearable technology.

Structure of Carbon nanotubes

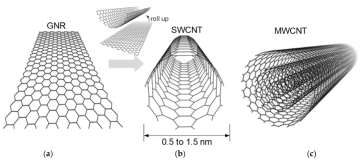

CNTs are actually nanotubes of carbon, having a diameter calculated in nanometers. Carbon nanotubes often allude as SWCNTs with breadths in nanometer. CNTs are considered often as structures derived from a 2D hexagonal cross-section of carbon iotas to form a hollow cylinder.

CNTs are frequently alluding to MWCNTs, formed by van der Waals connections. Chemical bondings of nanotubes are formed entirely of sp2 bonds and stronger when sp3 bonds are being formed to provide unique properties. The first structure of CNT was discovered in 1991 by Iijima. This name is given because of their hollow-like empty structure and the dividers shaped by single-particle thick sheet of carbon.

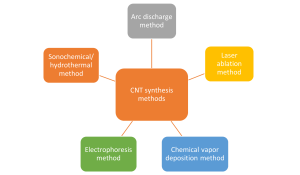

Synthesis of Carbon nanotubes

There are many methods of synthesis of CNT such as laser technique, chemical vapor deposition, HIPCO method, etc. Carbon nanotubes can display noteworthy electrical conductivity, have excellent elastic strength, heat conductivity, in light of structure as well as firmness of the connections linking carbon iotas. Likewise, they can be artificially restructured and to be used in numerous spaces of innovation, like gadgets, optics, composites (supplanting or supplementing strands), technology, and different uses in the field of material science.

Applications of Carbon nanotubes

CNTs are now being used as UV protection material for textiles and coating solicitation. Nano semiconductor oxides dissipate UV radiation and dispersing relies upon its size and frequency for the most part (Yetisen et al., 2016). Cotton strands are being operationalized with CNT. (Liu et al., 2008). CNT armor has been made outwardly of cotton surfaces show astonishing UV security by using 0.25% of carbon nanotube, hence developing UV resources.

The drawback of CNT usage is certainly coloration consequences in which the cotton, as well as other materials, becomes dark. To reduce this effect, UV resisting additives usage comes into place (Liu et al., 2008). UV assimilation nature of TiO2 can be clarified by solid band theory (Yang et al., 2004). The nanoscale TiO2 features great partiality to fabrics because of the huge explicit surface region (Zhang et al., 2009). CNTs, especially the SWCNT, have maintenance capacity at the UV space of the visible spectrum range. MWCNT is a potential utilization method for UV protection cases in the textile sector (Amini, Zohoori, Mirjalili, Karimi&Davodiroknabadi,2014).

CNTs are fire resistant as well as can conduct heat. Carbon nanotube can easily move warmth through adjusted nanotubes to shield the firemen from burning(Sullivan et al., 2015). These properties might empower class-leading PPE to guarantee safety. Montmorillonite with CNT filled with polyurethane back coating textures introduced a critical reduction rate in the maximum release of warmth, roughly 30-40% (Gieparda et al., 2012).

The flame retardant properties of MWNT nanomaterials are administrated in two cycles. Firstly, the structured network acts as a safeguard and resends critical portions of the emission back into the gaseous stage, decreasing the polymer defilement rate. Besides, the presence of CNT creates the heat connectivity of the polymer. Thus, the pinnacle heat discharge rate of MWNT increases with the MWNT content. Mostly insignificant warmth discharge rate is accomplished with containing 1 wt.% MWNT (Laoutid et al., 2009).

MWCNT offsets on cotton surface implementing vinyl phosphonic corrosive monomer and benzophenone as a stimulus for fire-resistant covering on cotton (Parvinzadeh Gashti & Almasian, 2013). CNT is often used for further developing fire retardancy in textile(Rahman & Mieno, 2015). Textile wastewater containing various material colors, inorganic salts, and natural added substances is an optimal case for the utilization of FO innovation to extricate unadulterated water from a, particularly mind-boggling framework as opposed to eliminating such countless impurities from water.

With the usage of the microwave as a source and CNT, E. coli bacteria can be easily removed from the water. Practically complete expulsion of E. coli microscopic organisms (100%) is proved to utilize CNTsC18 followed by CNTs (98%) and afterward a (Jauris et al., 2016)microscopic source (71%) for 12 sec (Al-Hakami et al., 2013). In the case of treatment of environmental pollution, photocatalysts like TiO2 can easily take control of. TiO2 with the combination of CNT increases photocatalytic nature (Byrappa et al., 2008). SWCNTs are adsorbents for dye removal. Metallic SWCNT shows overwhelmingly restricting energies bigger than that of semiconductor SWCNT when contrasting to a similar kind of color and design which can be used for textile wastewater ministration (Berutti et al., 2016).

As of late, a huge effort has been focused on elective energy transformation gadgets advancement with high energy and force densities because of the expansion of ecological issues and the proceeding with consumption of petroleum products. Supercapacitors are creating a huge impact in the textile research sector for their unique usages. Supercapacitors in textiles are run of the mill kinds of instances of these sorts of novel energy stockpiling gadgets and were planned by the same token straightforwardly changing over the material and textures into electrically conductive also electrochemically dynamic textures through distillation or covering strands with utilitarian meager layers such as CNT(Islam etal., 2017).

Layers of ultrathin corrosion treated with MWCNT on cotton materials for electro-chemical affidavit regarding MnO2 nanoflakes. Such conductive materials show remarkable adaptability between CNT and any substances. Usually, supercapacitors made from these conductive textile materials exhibit a high retention capacity and limit maintenance of 94.7%, which lasts 2100 cycles(Jiang et al., 2015). Furthermore, by doping antacid metal salts like LiCLO4 into the electrolyte to expand the deposition of applying nano carbons like double-walled carbon nanotubes to the anode to expand the charge accumulation ability in the supercapacitor, the efficiency of the energy collecting in supercapacitors has been improved (Hui et al., 2019). So, the extended efficiency of the supercapacitor is benefitting the textile field to a superior extent globally.

The need for antibacterial properties in fabrics is increasing day by day. Exceptionally purged SWCNT displays solid anti-infective movement (Kang et al., 2007). Generally, MWNT has less toxicity than SWCNT to bacterial activities(Kan et al., 2008). CNT has a stringy shape with a huge available outer surface region, with high perspective proportion, all around created mesopores which is beneficial for the antimicrobial property (Upadhyayula et al., 2009). The antibacterial impact of MWCNTs requires immediate contact among MUCNTs and microorganisms.

MWCNTs positively affect the antibacterial properties of the covered material examples. The decrease rates for both Gram-positive and Gram-negative microscopic organisms were 99.9% by the CNT inserted materials for any event, for the texture with 20 ppm focus. Recent investigations have shown precisely that CNTs add a glue-like capacity to microorganisms. They can be utilized in the expulsion of an assorted scope of organic toxins including microbes, infectious elements, and cyanobacterial poisons(Alimohammadi et al., 2012). Past investigations have shown that the antibacterial action of CNT against microorganisms.

For example, L.acidophilus and E.coli were assessed in a an experiment. CNT including SWCNT and MWCNT, all have wide range of antibacterial impacts (Song, Gao, Cheng, & Xie,2015). Thus, antibacterial activities of CNT are becoming reality through proficient research. Carbon nanotubes are a blessing for being used in lots of material science faculties because of their exceptional qualities which include mechanical, thermal, electrical, photochemical.

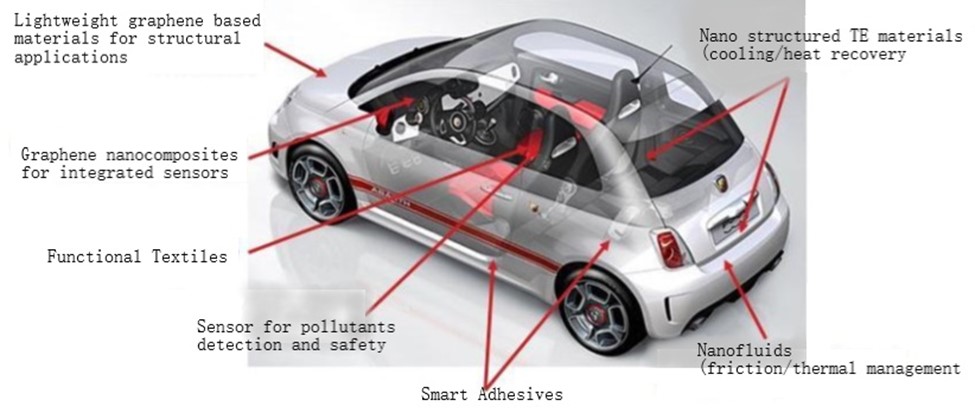

The interactions of humans and the environment can be beneficial with the commercial interest of CNT and its applications. Textile sector can be hugely benefitted in terms of UV protection, the antimicrobial ability of fabric, huge wastewater management, supercapacitors implementation, fire retardant for emergency services, and others by implementing and researching carbon nanotubes. CNT can open the possibility of composite material improvements for our day-to-day usage from customary attire and active apparel to defense dresses, geo-textiles, biomedical textiles, and so on.

The smart textile industry can take a giant leap with the help of viable CNT production solutions. Carbon nanotubes can likewise be artificially adjusted to introduce explicit nature to give properties appropriate for organic applications like biological implementations, upgraded material qualities.

MD. SAIFUL ISLAM SAAD1

1Student of Bangladesh University of Textiles, Textile Engineering Management, Batch 45, ID:201915030

Reference:

Al-Hakami, S. M., Khalil, A. B., Laoui, T., & Atieh, M. A. (2013). Fast disinfection of escherichia coli bacteria using carbon nanotubes interaction with microwave radiation. Bioinorganic Chemistry and Applications, 2013. https://doi.org/10.1155/2013/458943.

Amini. A., Zohoori., S., Mirjalili, A., Karimi, L., & Davidiroknabadi, A.(20140. Improvement in physical properties of paper fabric using multi-wall carbon nanotubes. Journal of Nanostructure in Chemistry,4,1082

Alimohammadi, F., Gashti, M. P., & Shamei, A. (2012). A novel method for coating of carbon nanotube on cellulose fiber using 1,2,3,4-butanetetracarboxylic acid as a cross-linking agent. Progress in Organic Coatings, 74(3). https://doi.org/10.1016/j.porgcoat.2012.01.012

Berutti, F. A., Garcia, A. P., Alves, A. K., Da Dalt, S., & Bergmann, C. P. (2016). Photocatalytic degradation of dyes using MWCNT-TiO2 composites as catalyst. In Ceramic for Environmental Systems (Vol. 257). https://doi.org/10.1002/9781119234463.ch2

Byrappa, K., Dayananda, A. S., Sajan, C. P., Basavalingu, B., Shayan, M. B., Soga, K., & Yoshimura, M. (2008). Hydrothermal preparation of ZnO:CNT and TiO2:CNT composites and their photocatalytic applications. Journal of Materials Science, 43(7). https://doi.org/10.1007/s10853-007-1989-8

Gieparda, W., Wesołek, D., & Rojewski, S. (2012). Montmorillonite and carbon nanotubes filled polyurethane back-coating for textiles with improved flammability properties and thermal stability. Journal of Nanostructured Polymers and Nanocomposites, 8(3).

Hui, C. Y., Kan, C. W., Mak, C. L., & Chau, K. H. (2019). Flexible energy storage system-an introductory review of textile-based flexible supercapacitors. In Processes (Vol. 7, Issue 12). https://doi.org/10.3390/PR7120922

Islam, M. S., Deng, Y., Tong, L., Roy, A. K., Faisal, S. N., Hassan, M., Minett, A. I., & Gomes, V. G. (2017). In-situ direct grafting of graphene quantum dots onto carbon fibre by low temperature chemical synthesis for high performance flexible fabric supercapacitor. Materials Today Communications, 10. https://doi.org/10.1016/j.mtcomm.2016.11.002

Jauris, I. M., Fagan, S. B., Adebayo, M. A., & Machado, F. M. (2016). Adsorption of acridine orange and methylene blue synthetic dyes and anthracene on single wall carbon nanotubes: A first principle approach. Computational and Theoretical Chemistry, 1076. https://doi.org/10.1016/j.comptc.2015.11.021

Jiang, Y., Ling, X., Jiao, Z., Li, L., Ma, Q., Wu, M., Chu, Y., & Zhao, B. (2015). Flexible of multiwalled carbon nanotubes/manganese dioxide nanoflake textiles for high-performance electrochemical capacitors. Electrochimica Acta, 153. https://doi.org/10.1016/j.electacta.2014.12.023

Kang, S., Herzberg, M., Rodrigues, D. F., & Elimelech, M. (2008). Antibacterial effects of carbon nanotubes: Size does matter! Langmuir, 24(13). https://doi.org/10.1021/la800951v

Kang, S., Pinault, M., Pfefferle, L. D., & Elimelech, M. (2007). Single-walled carbon nanotubes exhibit strong antimicrobial activity. Langmuir, 23(17). https://doi.org/10.1021/la701067r

Laoutid, F., Bonnaud, L., Alexandre, M., Lopez-Cuesta, J. M., & Dubois, P. (2009). New prospects in flame retardant polymer materials: From fundamentals to nanocomposites. In Materials Science and Engineering R: Reports (Vol. 63, Issue 3). https://doi.org/10.1016/j.mser.2008.09.002

Liu, Y., Wang, X., Qi, K., & Xin, J. H. (2008). Functionalization of cotton with carbon nanotubes. Journal of Materials Chemistry, 18(29). https://doi.org/10.1039/b801849a

Parvinzadeh Gashti, M., & Almasian, A. (2013). UV radiation induced flame retardant cellulose fiber by using polyvinylphosphonic acid/carbon nanotube composite coating. Composites Part B: Engineering, 45(1). https://doi.org/10.1016/j.compositesb.2012.07.052

Rahman, M. J., & Mieno, T. (2015). Conductive Cotton Textile from Safely Functionalized Carbon Nanotubes. Journal of Nanomaterials, 2015. https://doi.org/10.1155/2015/978484

Sullivan, J., Schulz, M., Vemaganti, K., Bhattacharya, A., Jetter, B. J., Shanov, V., Alvarez, N., & Kim, J. (2015). Carbon nanotube fabric cooling system for firefighters and first responders: Modeling and simulation. Journal of Fiber Bioengineering and Informatics, 8(1). https://doi.org/10.3993/jfbi03201501

Song, K., Gao, A., Cheng, X., &Xie, K. (2015). Preparation of the superhydrophobicnano-hybrid membrane containing carbon nanotube based on chitosan and its antibacterial activity. Carbohydrate polymers,130, 381-387.

Upadhyayula, V. K. K., Deng, S., Mitchell, M. C., & Smith, G. B. (2009). Application of carbon nanotube technology for removal of contaminants in drinking water: A review. In Science of the Total Environment (Vol. 408, Issue 1). https://doi.org/10.1016/j.scitotenv.2009.09.027

Yang, H., Zhu, S., & Pan, N. (2004). Studying the mechanisms of titanium dioxide as ultraviolet-blocking additive for films and fabrics by an improved scheme. Journal of Applied Polymer Science, 92(5). https://doi.org/10.1002/app.20327

Yetisen, A. K., Qu, H., Manbachi, A., Butt, H., Dokmeci, M. R., Hinestroza, J. P., Skorobogatiy, M., Khademhosseini, A., & Yun, S. H. (2016). Nanotechnology in Textiles. In ACS Nano (Vol. 10, Issue 3). https://doi.org/10.1021/acsnano.5b08176

Zhang, H., Millington, K. R., & Wang, X. (2009). The photostability of wool doped with photocatalytic titanium dioxide nanoparticles. Polymer Degradation and Stability, 94(2). https://doi.org/10.1016/j.polymdegradstab.2008.10.009

Check out these related articles: