Introduction

Sustainability has arrived in the textile industry. It is about more than the use of organic cotton and better working conditions. The consumption of water, energy and chemicals poses challenges for textile companies at every stage of the value chain. Sustainable business is characterized as an organization that has no negative impact on the environment or economy through its processes, products and manufacturing activities that meets the current demands with due concern to resource availability for future the generations by utilizing renewable resources. Creating awareness through a strong knowledge base of sustainable practices to the stake holders involved in order to achieve Green manufacturing and thereby imbibing the waste reduction and recycling practices will contribute to a sustainable business.

Origin of Sustainability

The concept of sustainability has its origin in the Report of the UN World Commission on Environment and Development of 1987, which is better known under the name Brundtland Report [1]. The aim of the Commission was to create a “development that meets the needs of the present without compromising the ability of future generations to meet their needs”[2]. Whereas the Brundtland report only focused on development and environment, today sustainability is seen in three dimensions: social, economic and environmental sustainability [1]. The United Nations states the three dimensions of sustainability in its Agenda for Development as following: “Development is a multidimensional undertaking to achieve a higher quality of life for all people. Economic development, social development and environmental protection are interdependent and mutually reinforcing components of sustainable development. (United Nations, 1997)”.

The idea of sustainability consisting of three dimensions derives from Elkington’s Triple Bottom Line Concept [3]. It states that a company´s success should not only be measured by the traditional financial bottom line but also by social and environmental aspects [4].

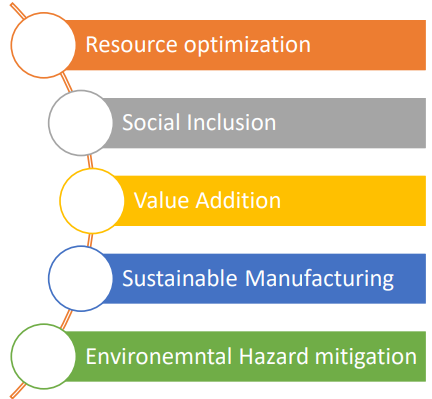

Principles to Achieve Sustainability

Sustainability in Textile Industry

Textile is one of the most hazardous engineering processes. Especially the wet processing industry produces a huge amount of effluents that is polluting our water base extensively. So, the sustainable development of the textile industries must be keeping in mind the negative impacts on environment and proper mitigation plans must be implemented. To achieve sustainable development these are the five principles that the industry must adopt. But achieving all these are associates with costs. Business cannot adopt sustainable principles compromising the competitiveness. That is the balance the industry must find out to adopt sustainable practices gradually so that the additional costs associated with going sustainable doesn’t affect the competitiveness.

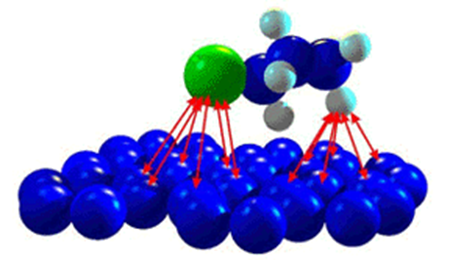

Sustainable Manufacturing and Clean Environment

Sustainable manufacturing is manufacturing products with such process that are not polluting, conserve energy and natural resources, economically sound and safe for employees, communities and consumers. Industry must continuously look for less hazardous options for production and ensure proper mitigation plan accordingly. Running vigorous awareness building and knowledge sharing programs and strengthening law and law enforcing agencies are also important to ensure a clean environment.

Difference between conventional fabric and sustainable fabric

Wearing clothing made with sustainable fabrics is more than just an environmental choice, although the repercussions are huge and consequently turning rivers purple. Conventional or traditional fabrics (not eco-friendly) are produced with harmful chemicals such as pesticides, insecticides, flame retardants and petrochemicals that are endocrine disruptive, cause skin irritations or increase the growth of cancer cells. Even after laundering, some of those chemicals still remain in your clothing.

We put ourselves at risk everyday with the amount of toxins we are exposed to through our food, beauty products and clothing and we really don’t know how it is affecting us. People keep risking their life without knowing how it will affect them and their children. Better quality and better fabrics will be worth the investment in the long run. The manufacturing process for conventional fabrics vs. sustainable fabrics is listed below:

Conventional Fabrics

👉Nylon: Nylon fabric is manufactured with petroleum and treated with several chemicals such as formaldehyde to prevent shrinkage. Producing nylon creates a greenhouse gas that is more potent than carbon dioxide. Nylon is not biodegradable.

👉Polyester: Polyester is petroleum based that can be hard to recycle and biodegrade. It is made with carcinogenic chemicals that remain trapped in the fibres. Polyester acts as endocrine disruptor, which affects your reproductive organs or may lead to cancer.

👉Rayon: Rayon fibres are made from wood pulp, which is better than petroleum, but are leading to deforestation. Manufacturing rayon is a chemical intensive process that is harmful to humans and the environment.

👉Cotton: Even though cotton is a natural fabric and biodegradable, it is harvested with chemicals such as pesticides that have large detrimental effects. Producing cotton is water and energy intensive. It takes about 700 gallons of water to manufacture one t-shirt and 2,600 gallons to make a pair of jeans.

Manufacturing conventional fabrics is leading to climate change, polluted waters and unliveable towns. Fabrics that are produced in the United States are somewhat better because waste water and chemicals are either recycled or treated.

Sustainable Fabrics

👉Tencel: Tencel is a natural man-made fibre that is extracted from raw material wood. Producing tencel is eco-friendly because it is a closed-loop process that recycles the chemicals used to create the fibre. It is biodegradable and anti-bacterial.

👉Modal: Modal is a semi-synthetic fibre made of pulp from beechwood trees. These trees rejuvenate on their own without planting making them very sustainable. Manufacturing modal is also closed loop, which conserves energy.

👉REFIBRA™: technology involves upcycling substantial proportion of cotton scraps e.g. from garment production, in addition to wood pulp, where the raw material is transformed to produce new virgin TENCEL™ Lyocell fibres to make fabrics and garments which is commitment to innovation and ecology, to drive circular economy solutions in the textile world.

👉ECOVERO™: LENZING™ ECOVERO™ Viscose fibres are derived from sustainable wood and pulp, coming from certified and controlled sources.

- up to 50%loweremissions&water impact than generic viscose.

- LENZING™ ECOVERO™ fibres have been certified with the EU Ecolabel as meeting high environmental standards throughout their life cycle fibres are robustly traceable in the final product, assuring you that your purchase contains genuine ECOVERO™ Viscose fibres.

👉Repreve: Repreve is made from recycling ocean waste plastic bottles.

Due to the process, lack of cheap chemicals, and environmental concern, eco-friendly fabrics are more expensive to manufacture. For example, a yard of polyester can be as low as $.99 per yard while modal can average $5 per yard. The cost of producing a dress with eco-friendly fabric can be 5 times more, which doesn‘t even consider labour costs if you are designing in the United States.

References:

1. Kuhlman, T.; Farrington, J. What is Sustainability? Sustainability 2010, 2, 3436-3448.

2. Shah, M.M., Sustainable Development, in Encyclopedia of Ecology, S.E. Jørgensen and B.D. Fath, Editors. 2008, Academic Press: Oxford. p. 3443-3446.

3. T. F. Slaper and T. J. J. I. b. r. Hall, “The triple bottom line: What is it and how does it work,” vol. 86, no. 1, pp. 4-8, 2011.

4. Markley, M. J.; Davis, L. J. I. J. o. P. D.; Management, L., Exploring future competitive advantage through sustainable supply chains. 2007.

Texpedi.com

Check out these related articles: