Nanomembrane Excellence: Unveiling the Potential of Crosslink–Chitosan/Activated Carbon | Chemical and biological contaminants present in environments such as in water sources are a constant concern for human health. Everyday more than 14,000 people die of waterborne diseases [1]. For the betterment of human life, before consumption of water, these pollutants are to be eliminated from their sources. Pollutants such as dyes, heavy metals, pesticides and pharmaceutical wastes are alien to groundwater and rivers thereby impacting negatively on the ecosystem. Membrane separation techniques, precipitation, ion-exchange, electrochemical, adsorption and oxidation processes are among the science and engineering approaches toward waste water management but they have their limitations toward efficiency. Among them, adsorption techniques are highly effective and economical [2].

Introduction

Chemical and biological contaminants present in environments such as in waterothing, bioengineering and biotechnology and environmental applications. Electro-spun nanofibers possess high density of pores, high surface area to volume ratio, high permeability, low basis weight and small fiber diameter [3].

These properties are suitable to be used as filtering media in water and air filtration applications. Although, polymeric nanofibers are currently employed for commercial applications in air filtrations, they are yet to be exploited for real applications in water domain. Also, the tendency of the Nanomembranes to selectively permeate moisture and thereby enhance breathability and block the chemical vapours made them suitable to be applied in air filtration applications such as in protective clothing domain in textile industry [4] for protection against chemical and biological (CB) warfare contaminants [5-7].

What is chitosan?

Chitosan is a well-known organic and biodegradable polymer made of a long N-acetylglucosamine biopolymer chain. Chitosan is a chitin derivative formed by the deamination of chitin, whereas chitin is a long-chain polymer of N-acetylglucosamine, a glucose derivative found in the shells of crabs, lobsters, shrimps, and insects.

What is electrospinning?

Electrospinning is a fiber manufacturing technique that use electric force to pull charged threads of polymer solutions or polymer melts up to fiber sizes of a few hundred nanometres. Electrospinning is the combination of electro spraying with traditional solution dry spinning of fibers. To produce solid threads from solution, no coagulation chemistry or high temperatures are required. As a result, the technique is particularly well adapted to the manufacturing of fibers containing big and complicated compounds. Electrospinning from molten precursors is also used; this approach assures that no solvent enters the final product.

Electrospinning is a suitable process for making nanofiber from macromolecule like chitosan. Electrospinning setup consists of a spinneret, high voltage power supply and a grounded collector. Electric charge is applied between the spinneret and collector. When a surface charge is induced on a polymer fluid spherical pendant droplet deforms to conical shape. When the electric field surpasses a certain value, electrostatic repulsion force of surface charges overcome surface tension and a charge fluid jet is ejected from the tip of cone known as Taylor cone.

|

| Figure 1. Electrospinning |

How to prepare Chitosan/Activated Carbon Nanomembrane?

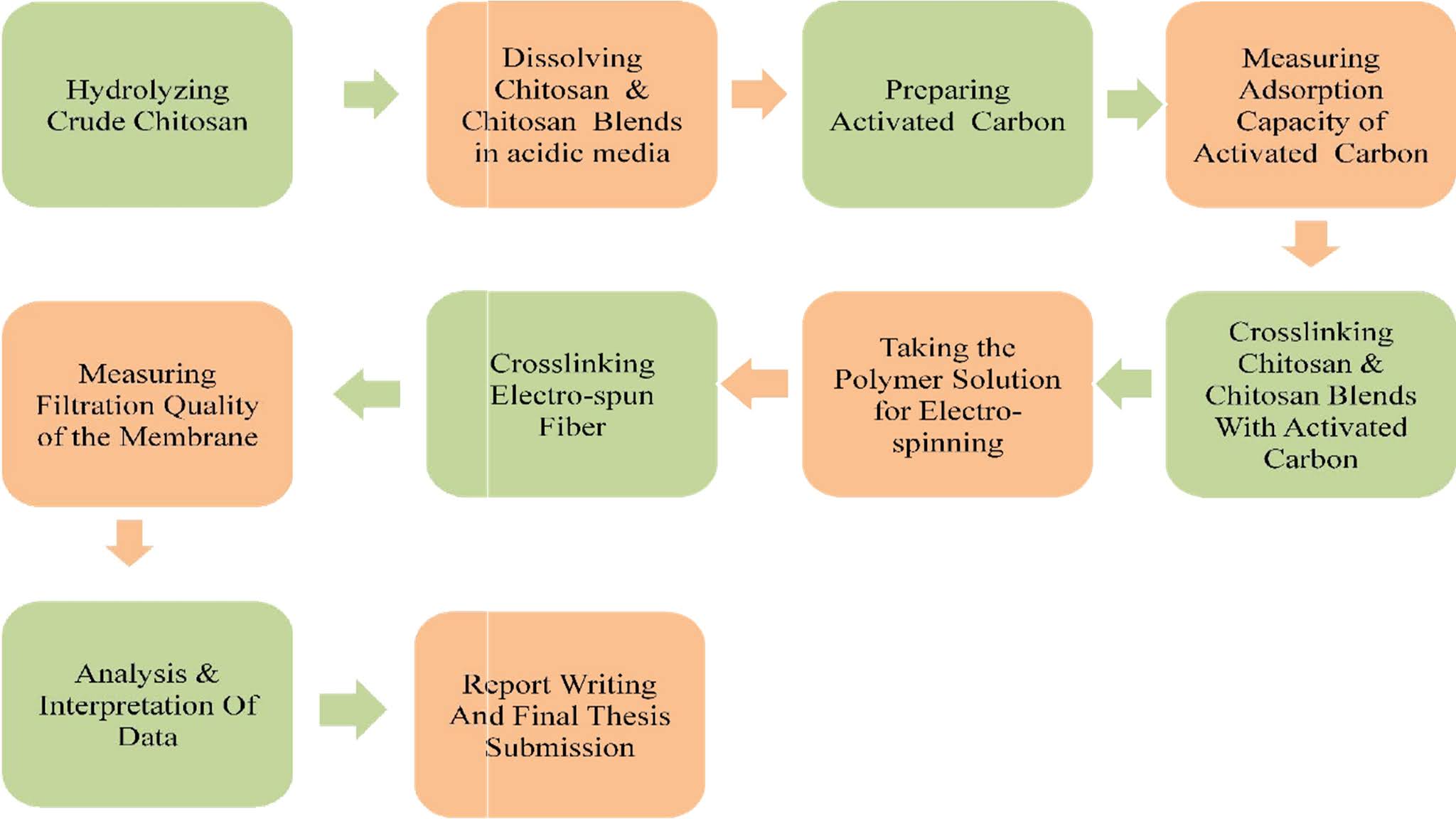

The production of Chitosan/Activated Carbon Nanomembrane involves the following steps as (a) chitosan preparation, (b) Activated Carbon preparation, and (c) producing Chitosan-Activated Carbon infused Nanomembrane via Electrospinning process. The process steps for each of these stages are mentioned below.

|

| Figure 2. The step-by-step process flow diagram of producing Chitosan-Activated Carbon infused Nanomembrane. |

(A) Preparation of Chitosan

- Crude chitosan is hydrolysed 50 wt.% of NaOH solution for 12-48 hrs at 95℃ for reducing molecular weight.

- 90% acetic acid, sodium acetate, formic acid, tri-chloro-acetic acid, tri-floro-acetic acid solution system is used for dissolving chitosan and chitosan blends. Polyvinyl acetate (PVA) and polyethylene oxide (PEO) are mainly used as binder. For chitosan blends 7-9 wt.% of PVA or PEO is dissolved in water by stirring.

(B) Preparation of Activated Carbon

Activated carbon is prepared from oil palm shell following two stages of carbonization and activation. The carbonization includes: (i) washing precursor to remove dirt, (ii) drying in an oven at 700C followed by grinding and sieving to discrete sizes (1-2mm), and (iii) carbonization at 7000C under purified nitrogen (99.995%) in a stainless steel vertical tubular reactor. The activation stage involves soaking the char in potassium hydroxide, where the char to KOH impregnation ratio is 1:0.5 (wt%), in a tubular glass reactor placed in a modified microwave oven. Nitrogen flow is usually kept for some time before microwave treatment to outgas air.

(C) Producing Chitosan-Activated Carbon infused Nanomembrane via Electrospinning

The prepared activated carbon is mixed with chitosan and chitosan blends by crosslinking (using suitable crosslinker). For Electrospinning, polymer solution is taken in syringe or glass capillary. An Electrospinning voltage of 0-30 kV is tried for all the solution. Fibers are collected on aluminium foil. Electro-spun fibers are crosslinked (using suitable crosslinker) to make it insoluble in aqueous, acidic and basic medium. The filtration quality of the Nanomembrane can be measured using waste water allowing to pass for a certain duration. The flow diagram of producing Chitosan-Activated Carbon infused Nanomembrane is given below:

Conclusion

This Chitosan-Activated Carbon infused Nanomembrane can filter & purify waste water in a hygienic and cost effective way. This membrane is very much effective in the effluents and waste water treatment especially in the Textile Industry. Now-a-days it is one of the most burning issues to ensure the eco-friendly processes. There are so many existing processes or technologies used in water treatment but most of these are not eco-friendly. That is why this type of Nanomembranes are of great importance for the Textile industry and environment as well.

References:

- West, Larry (March 26, 2006), “World Water Day: A Billion People Worldwide Lack Safe DrinkingWater”.

- W.S. Wan Ngah, L.C. Teong, M. Hanafiah, Adsorption of dyes and heavy metal ions by chitosan composites: a review, Carbohydr. Polym. 83 (2011)1446.

- Wang, C.; Yan, E.; Huang, Z. Zhao, Q.; Xin, Y. Fabrication of highly hotoluminescent TiO2/PPV Hybrid nanoparticle-polymer fibers by electrospinning, Macromol. Rapid Commun. 28 (2007) 205–209.

- Schreuder, H.L.; Gibson, X.; Gibson, P. Transport properties of electrospunnanofibers. Int. Nonwovens J. 11 (2002)21–27.

- Sundarrajan, S.; Ramakrishna, S. Fabrication of nanocomposite membranes from nanofibers and nanoparticles for protection against chemical warfare stimulants, J. Mater. Sci. 42 (2007) 8400– 8407.

- Ramakrishnan, R.; Sundarrajan, S.; Liu, Y.; Barhate, R.S.; Lala, N.L.; Ramakrishna, S. Functionalized polymer nanofibre membranes for protection from chemical warfare stimulants. Nanotechnology 17 (2006)2947–2953.

- Ramakrishnan, R.; Ramakrishna, S. Zinc titanatenanofibers for the detoxification of chemical warfare stimulants. J. Am. Ceram. Soc. 90 (2007)1836–1842.

Texpedi.com

Check out these related articles: