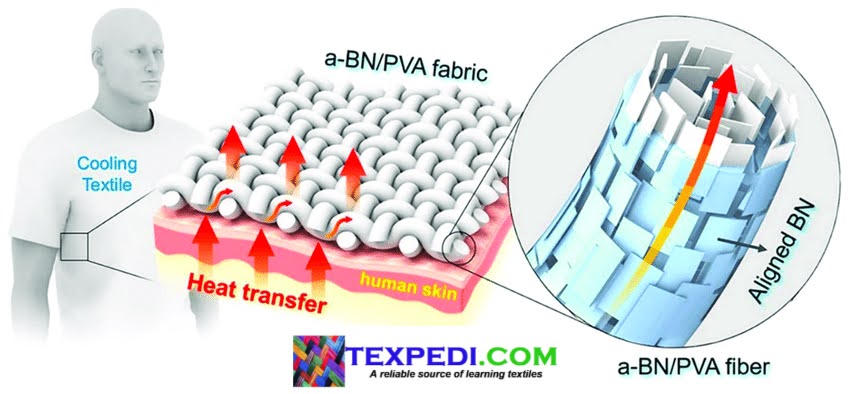

Different types of fabrics are used in sportswear. Ensuring wearers’ comfort is the principal objectives of these types of fabrics. This type of fabric is such that players can wear jerseys made of that fabric comfortably for a long time. With the development of technology, various types of fabrics have already been developed to meet different needs. At present, not only comfort issues are considered for these types of fabrics but also various intelligent features such as thermal ventilation, geotagging, as well as various Medi-features (heartbeat, blood pressure, etc.) are achieved from them. This type of fabric can be termed as intelligent fabric or thermoregulating fabric.

Introduction

The heat and moisture transfer behaviour of clothing has long been recognized to be critically important for human survival. Thermoregulation according to the textile glossary is defined as the ability of textile to maintain the constant temperature conditions without being affected by the dynamic environment conditions outside. As far as clothing and comfort are concerned, physical, physiological and some psychological factors influence the comfort which is a state of mind.

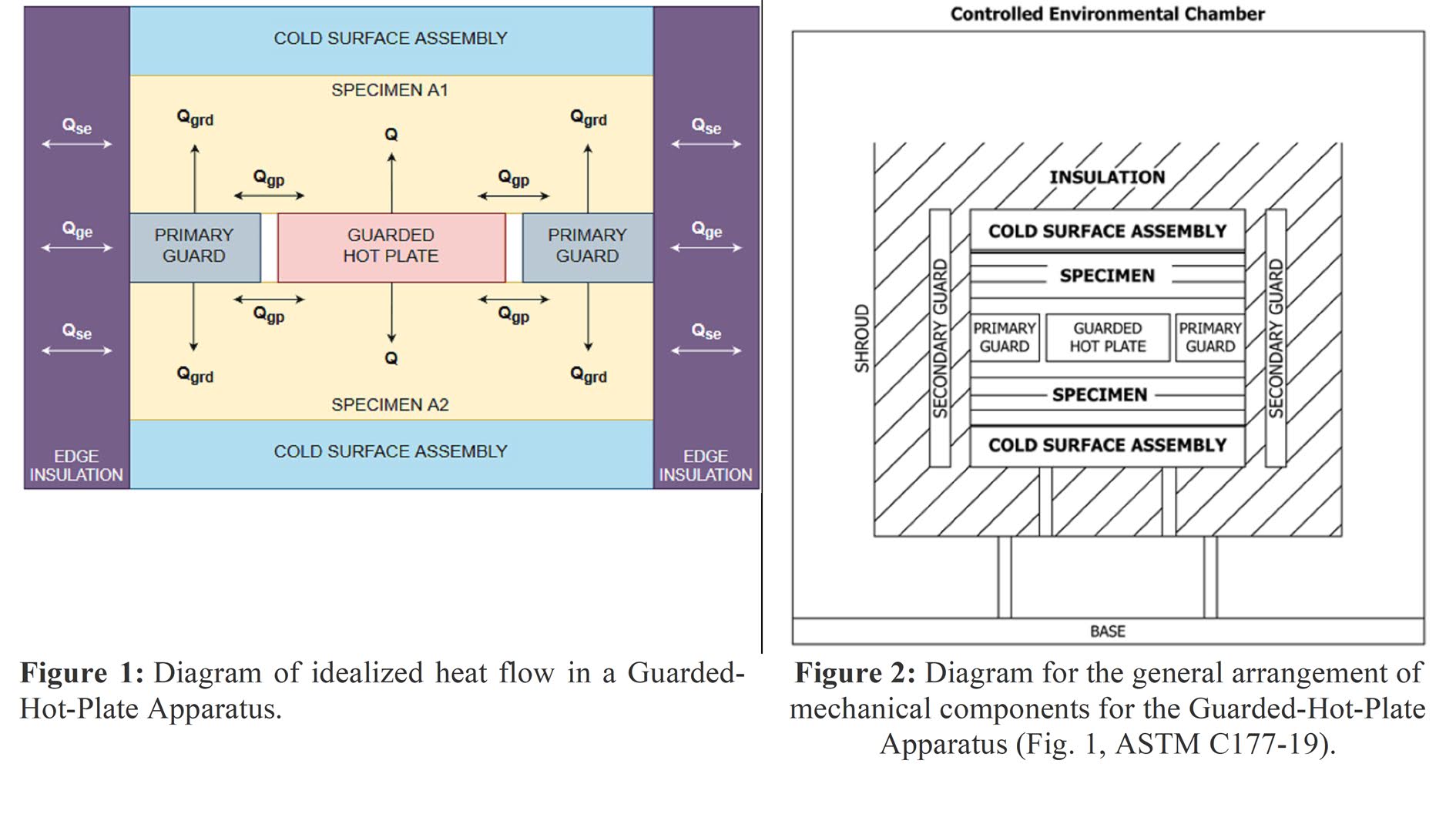

|

| Figure 1. Schematic view of thermoregulating fabric[source: https://doi.org/10.3390/inventions3020023] |

Smart textile is an emerging area in textile field which is becoming more significant by the demand of society through consumer needs. Despite the increasing impact of science and technology, smart textile demands the advancement through interdisciplinary support like fashion, design, engineering, technology, human and life sciences. In textile sector, smart textiles have application in interior textiles, technical textiles and clothing in which the last one contains higher percentage in terms of usage of smart textiles.

What is Thermoregulating fabric?

Melt spun filaments in combination with Phase Change Materials (PCMs) can be used to create a thermoregulating fabric. PCMs are kind of smart materials which were used in clothing by US National Aeronautics and Space Administration (NASA) in 1980 to make thermo-regulated garment for space and to protect apparatus in space with 7 drastic temperature changes. Textiles made by such smart materials are able to provide passive insulation and protect the user from extreme environment. Thermoregulating fabric is a type of functional textile that contains low-temperature phase change materials (PCMs) or microencapsulated phase change materials (Micro-PCMs), or a type of block copolymer with segments that change phase at low temperatures.

What is phase change material?

Phase change material is a substance that releases/absorbs sufficient energy in phase transition to provide useful heat/cooling. Normal human body temperature is 37 °C which increases up to 38 °C, 39 °C or occasionally 40 °C during exercise. The most comfortable skin temperature is 33.4 °C and when it changes more than 4.5 °C below or above the comfort temperature, human body feels uncomfortable. PCMs are attractive for storing energy in all the available heat energy storage techniques due to high density, compact storage system and high latent heat.

A large number of inorganic and organic PCMs are available in the temperature range of -5°C to 190°C. The organic phase change materials ranging from 18-65°C are used in textiles and buildings to enhance thermal comfort effect. Among all the PCMs, n-octadecane is usually used for the textile application having melting point of 28°C.

Market of Phase change materials:

Currently, phase change materials are being used in different textiles including bedding, apparel, footwear and non-woven under the trade names Outlast™, TemperTex™ and ComforTemp®. Outlast Technologies has succeeded in marketing viscose and polyacrylonitrile (PAN) fibers incorporated with MPCM. But if we think about Bangladesh, we are doing nothing on this immerging sector of smart textiles.

How PCM works?

Phase Change Materials store energy as latent heat which is the most suitable way of storing high amount of energy with a smaller difference of temperature. The stored energy is released to surroundings in a reverse cooling process. Paraffins are organic phase change materials which absorb approximately 200 J/g of latent heat during phase change. This high amount of heat is released to surroundings during reverse cooling process called crystallization. By incorporating phase change materials to textiles, their thermal management capacity can be substantially enhanced.

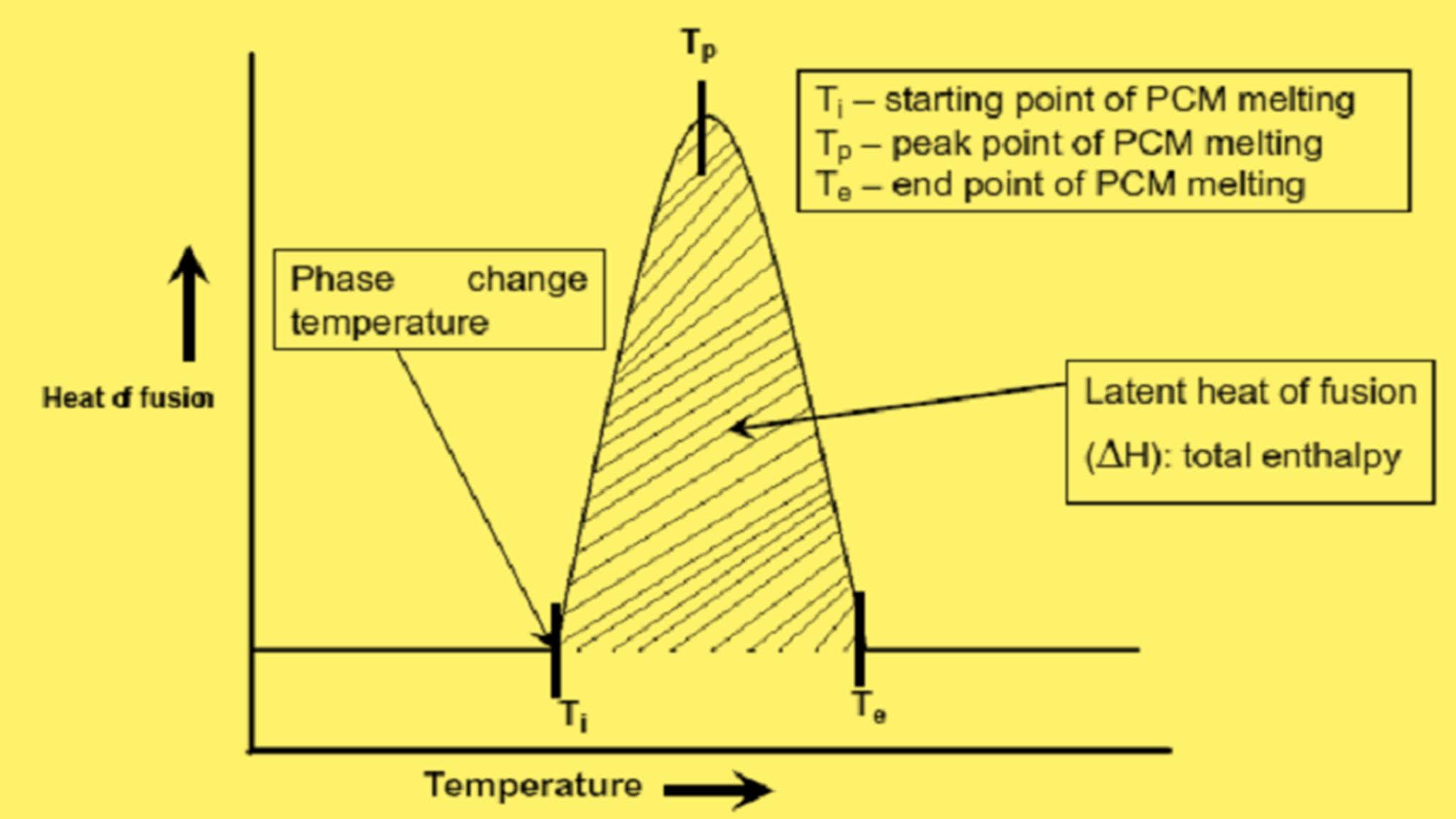

|

| Figure 2. Heat energy vs temperature behavior of PCMs |

Chemical bonding is responsible for the above phenomenon as increase in temperature goes to break chemical bonding in the molecules of PCM material causes material to melt resulting in storing heat energy which is subsequently released during crystallization process restoring chemical bond.

Types of PCMs?

Phase change materials are theoretically able to change their phase at nearly constant temperature and are able to store large amount of energy. More than 500 natural and synthetic PCMs are known in addition to water but they differ in their melting points and heat storage capacities. The most common among all are paraffin which can be encapsulated and then either incorporated into fiber or applied via coating.

How to apply PCMs to textiles?

- Core Spun: Fabrics can be made by using core spun yarn where we must use PCM incorporated fibers (i.e., polyester, acrylic, polypropylene, PET) in the core and wrap it with comfortable breathable fibers (like silk, cotton, micro-denier polyester etc.)

- Hollow Fiber: Using hollow fiber is another method of creation. If hollow fibers are used, then microencapsulation of PCM`s isn`t necessary. We just have to inject PCM in the hollow space of the fiber. Then the fiber surface will be use as the capsule of the material.

- Incorporation of Microencapsulated PCM in the fiber: By this process incorporation of MPCM is done into the fiber (like-acrylic, polyester, polypropylene etc.) Incorporation is the safest method of using PCM as by this process leakage of PCM is quite difficult.

- Melt Spinning: Melt spinning is another process of using PCM in clothing. In this process, manmade fiber chips are mixed with liquid PCM then the solution is extruded through the spinneret and fiber is formed by melt spinning.

- Coating: If we aren’t interested in using PCM at fiber phase then we can also apply it as a coating over the manufactured fabric. Pad-dry-cure, knife-over-roll etc. are the process by which coating of PCM is given over the fabric. But the problem of making coated fabric is, coating reduces the air permeability and breathability of fabric as well as increase the flammability of the fabric.

- Lamination: Making laminated fabric is another way which isn`t widely used as a method.

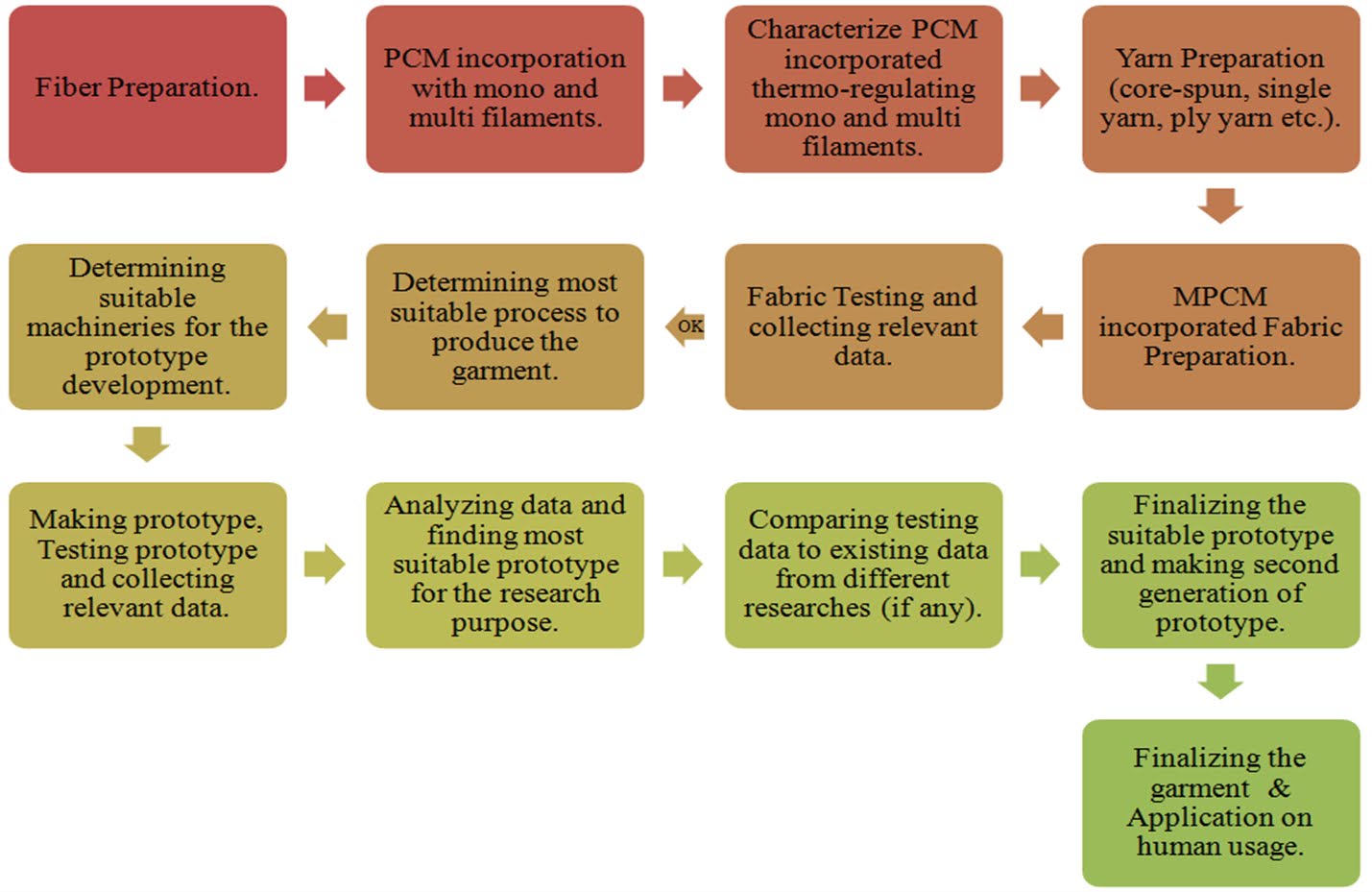

|

| Figure 3. Step-by-step process flow chart of producing thermoregulating fabric using phase change materials. |

|

| Figure 4. Incorporation of phase change materials with textiles |

This type of thermoregulating fabric can regulate the temperature both in warm and cool weather and can be preferably used in smart sportswear.

References

- Kashif Iqbal, “Experimental and Numerical Studies of Thermoregulating Textiles Incorporated with Phase Change Materials”

- G. Havenith, C. Smith, and T. Fukazawa, “The Skin Interface – Meeting Point of Physiology and Clothing Science,” Journal of Fiber Bioengineering and Informatics,

- Q. H. Meng and J. L. Hu, “A poly(ethylene glycol)-based smart phase change material,” Solar Energy Materials and Solar Cells, vol. 92, pp. 1260-1268, Oct 2008.

- H. Mattila, Intelligent textiles and clothing USA: Woodhead Publishing, July 2006.

- A. Schwarz, L. Van Langenhove, P. Guermonprez, and D. Deguillemont, “A roadmap on smart textiles,” Textile Progress, vol. 42, pp. 99-180, 2010.

- J. Mengjin, S. Xiaoqing, X. Jianjun, and Y. Guangdou, “Preparation of a new thermal regulating fiber based on PVA and paraffin,” Solar Energy Materials and Solar Cells, vol. 92, pp. 1657-1660, 12// 2008.

- W. L. Cheng, N. Liu, and W. F. Wu, “Studies on thermal properties and thermal control effectiveness of a new shape-stabilized phase change material with high thermal conductivity,” Applied Thermal Engineering, vol. 36, pp. 345-352, Apr 2012.

- R. Cox, “Synopsis of the new thermal regulating fiber Outlast,” Chemical fibers international, vol. 48, 1998

- M. M. Farid, A. M. Khudhair, S. A. K. Razack, and S. Al-Hallaj, “A review on phase change energy storage: materials and applications,” Energy conversion and management, vol. 45, pp. 1597-1615, 2004.

- W. Bendkowska and H. Wrzosek, “Experimental study of the thermoregulating properties of nonwovens treated with microencapsulated PCM,” Fibres& Textiles in Eastern Europe, vol. 17, p. 76, 2009

Texpedi.com

Check out these related articles: