COVID-19 or Novel coronavirus soon after being firstly traced in the human body on 31, December 2019 in Wuhan-Hubei in China, spread all over the world. This epidemic disease destroyed everything wherever it headed to. Due to this novel coronavirus pandemic, the entire world has been bound to be stopped. Everything including education, business, politics and even war has to be stopped.

Everyone is running after discovering the way to get relief from COVID-19. Researchers across the world are trying rigorously to find out a solution, while all the other sectors are trying to adapt themselves to this new normal situation. Everything has been converted into the virtual format.

COVID-19 and RMG industry

COVID-19 has affected every sector across the entire world; no matter whether it is the rich or poor countries. The economic giant countries like the USA, UK, Germany, Canada, Italy and so on are also the severe victims of this pandemic. These developed countries also have to suffer a lot despite having a developed medical system equipped with modern technology.

They cannot even accommodate all the patients in the hospital and finally having no other alternatives left the old people at home helplessly. Everything has to be shut down to prevent the mutual transmission but in return, the entire world is facing a crucial situation. Almost every sector has been affected by this disease.

Textile Industry

Among all the manufacturing industry affected, the textile and apparel industry is facing a severe crisis. Most of the factories of this industry are export-oriented and the remaining are for supporting the local markets. Due to the covid-19/coronavirus, all the business across the world has been kept on hold. The factories cannot produce the goods properly due to lack of the necessary raw materials coming from the outside or the absenteeism of the workers. Workers are afraid to come out of the house for fear of being affected by Covid-19.

As a consequence of this situation, the textile manufacturing factories like the spinning mill, knitting mill, weaving mill, dyeing mill, printing mill and others are facing an unanticipated result. At the very beginning, they could successfully handle the situation as they got sufficient raw materials at hand and the smooth WIP (work-in-progress). But after a couple of months, the raw materials supply especially fibres, dyes, chemicals, fabrics has been hampered which has become the big issue to think about.

It has been found from intensive research that in April all types of textile factories suffered the maximum production drops and then gradually they could minimize the production drop. Still, the textile industry is trying to reduce the production drop and bring back the normal production situation. But in fact, they are literally struggling to do so.

There is no more a balanced demand-supply situation right now. The demand from the customer or fashion buyer has been reduced remarkably. Buyers are not ordering for new garments or existing garment orders are being kept on hold. Due to the lack of fibres, spinners cannot produce yarns and accordingly knitting or weaving industry cannot be supported by the sufficient yarns or the spinners are producing the normal amount of yarns from the fibres already booked and in-housed in the necessary quantities but the knitting or weaving industry does not consume as before due to less production, the factory shut down, etc. Dyeing and all the other subsequent manufacturing factories are facing the same as mentioned for the spinning and knitting/weaving industry.

Apparel Industry

This is the most severely affected part of the textile and apparel industry. Because the textile and apparel industry is the most populated sector, where millions of people are working. But due to the lockdown period imposed by the government, people cannot go out home to the workstation. So, workers’ absenteeism has been increased and consequently, production has been hampered significantly. Another big reason is that fashion buyers are not taking any products during the pandemic period because all of their outlets are closed due to this current situation.

That is why buyers are requesting the manufacturing factories to keep the goods in the factory which causes a huge amount of inventory management cost for the suppliers and of course, there is the risk of product damage, loss, etc. In addition, factory owners are seriously struggling to maintain everything particularly the salary and/or wages of the workforces, as they are not getting any promised payments from the buyers.

Thousands of workers are losing their jobs every day or employees -both workers and engineers are suffering from the pay-cuts up to a maximum of 60% found the research done. As a result, they cannot lead a simple regular life as before. They cannot afford buying their regular commodities with the wages/salary they are getting during the pandemic.

|

| Figure. Production status during novel coronavirus pandemic. |

Another critical issue in the apparel sector is maintaining proper hygiene. Workers have no other alternatives and they know they must go for work; otherwise, they cannot survive. Business owners are also trying hard to survive in critical moments. This is the somewhat lose-lose-lose situation for all the parties -buyers, manufacturing business owners and the workers.

The factories are offering hygiene measures like soap, facial mask, sanitizer, soapy water spray, head-cover, etc. to ensure their workers. But this is the scenario of the big company. Think about small and medium factories. They are miserably struggling and about to be shut down. This covid-19/coronavirus has killed so many dreams, with so many lives. Yesterday’s potential entrepreneurs are bankrupt today.

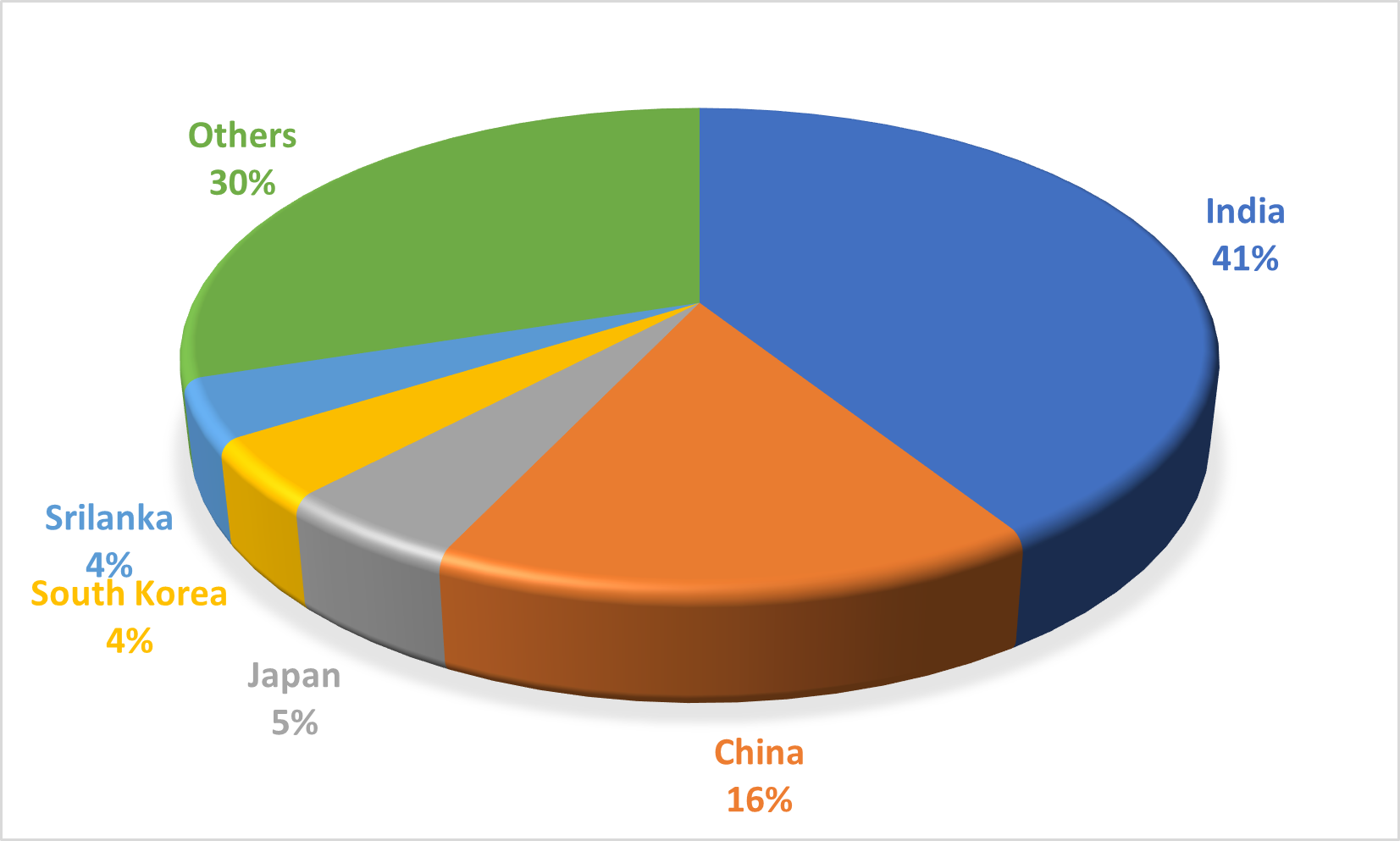

Garment Order and Export Status

As almost all the fashion outlets are closed during the pandemic situation, buyers are bound not to bring the garment items to their warehouses. That is why they are not ordering for new goods or postponing the existing orders (work-in-progress) or even cancelling the orders. Although receiving no new orders, is threatening the textile and apparel industry but more loss is from order cancellation.

Most of the order cancellation occurs in the middle of the order that means a huge loss for the manufacturing company. Garment orders and exports are also being hampered due to the closure of international flights. Supply cannot ship the goods or buyers cannot receive the items timely.

Adapting to the new normal situation

Surprisingly, this disease has been around for a long time. We should find a way out to adapt to this situation. Education, business, manufacturing industry, everything should reform their structures. Accordingly, the textile and apparel industry must make some changes to sustain. Currently, there are very few fashion item orders in the factory. Buyers are ordering for medical items especially facial mask, body gown, surgical gown, head-cover, foot-cover, hand gloves, and other protective equipment.

There is a huge demand of advanced textile materials like virus-protected fabrics with anti-virus finishes. More and more researches are utmost to face crisis moments. Depending merely on the basic fashion items at this age is nothing but foolishness. Another most important thing is to strengthen the backward linkage industry and ultimately reducing the dependence on other countries for raw materials.

Look at the current situation, manufacturing factories cannot run their production due to the raw materials crisis as because they cannot come as all the international flights are stopped. One industry can be strong but can never be the strongest with only one part of the supply chain no matter whether it is yarn or fabric manufacturing or garments manufacturing. If you depend on others, that means your navigation is on others hand. You can collapse at any time. So we have to focus on each and every chain of the entire textile supply chain.

Conclusion

The effect of covid-19/coronavirus on the textile and apparel industry found from research, does not actually present the real scenario of the future of this industry. It can at best predict the probable scene in future, though there is no such research so far. Research done so far is on the current scenario and this current scenario is actually the reflection of the previous season for which industry already got the garment orders and could order & in-house all the necessary raw materials.

Business status is being affected due to production drop caused by the employee absenteeism and shipment problems. The existing system is already obsolete and to protect this business, policy-makers should rethink about the business strategy, production tools & techniques, produced items.

You may also like:

Texpedi.com