Pierce Geometrical Model | Geometrical modeling of different fabrics is not attributed to a single individual or discovery but rather has evolved over time through the contributions of many textile scientists, mathematicians, and engineers. It is a collective and ongoing effort to understand, analyze, and optimize fabric structures using mathematical and computational tools.

Various researchers and experts in the fields of textiles, textile engineering, mathematics, and computer science have made significant contributions to the development of geometrical modeling techniques for fabrics. These contributions span centuries, from early efforts to describe fabric patterns mathematically to contemporary applications of computer-aided design and simulation.

The properties of the fabric depend on the fabric structure. The formal structure of a woven fabric is defined by weave, thread density, crimp and yarn count. The interrelation between fabric parameters can be obtained by considering a geometrical model of the fabric. The geometrical model is mainly concerned with the shape taken up by the yarn in the warp or weft cross-section of the fabric.

Pierce Geometrical Model:

The basic relationship between geometrical parameters:

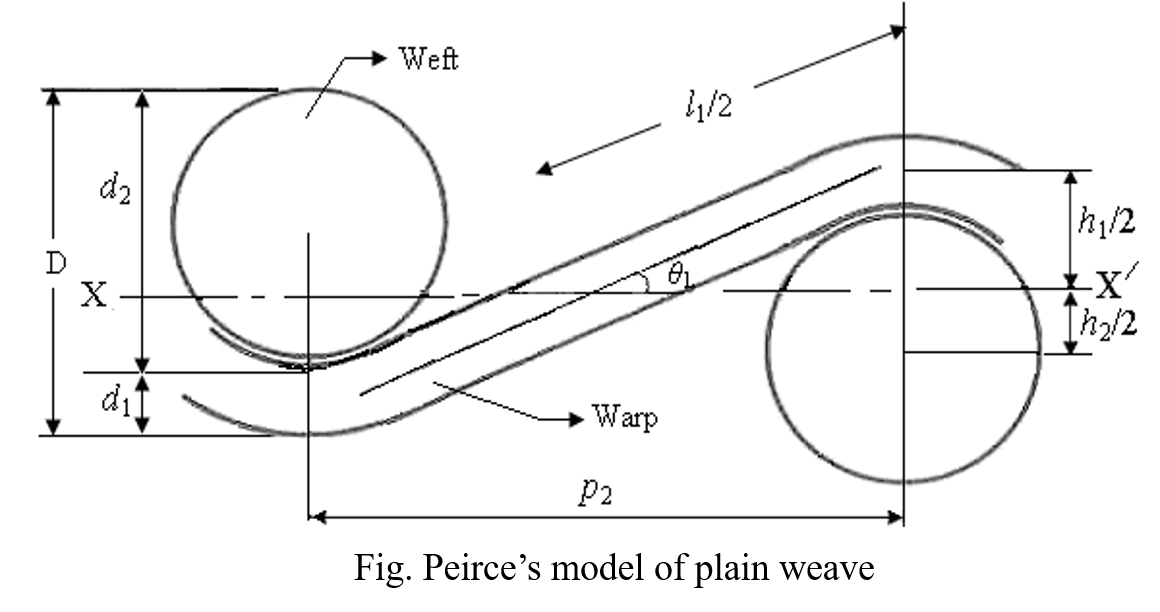

Figure represents a unit cell interlacement in which the yarns are considered inextensible and flexible. The yarns have circular cross-section and consist of straight and curved segments. The main advantages in considering this simple geometry are:

1. Guide to the maximum density of yarn packing possible in the cloth.

2. Helps to establish relationship between various geometrical parameters.

3. Provide information on the relative resistance of the cloth to the passage of air, water or light.

4. Able to calculate the resistance of the cloth to mechanical deformation such as initial extension, bending and shear in terms of the resistance to deformation of individual fibres.

From the two-dimensional unit cell of a plain woven fabric, geometrical parameters such as thread-spacing, weave angle, crimp and fabric thickness are related by deriving a set of equations. The symbols used to denote these parameters are listed below:

d – Diameter of thread,

p – Thread spacing,

h – Maximum displacement of thread axis normal to the plane of cloth (crimp height),

θ – Angle of thread axis to the plane of cloth (weave angle in radians)

l – Length of thread axis between the planes through the axes of consecutive cross- threads (modular length)

c – Crimp (fractional)

D = d1 + d2 [Suffix 1 and 2 to the above parameters represent warp and weft threads respectively.]

In the above figure projection of yarn axis parallel and normal to the cloth plane gives the following equations:

Three similar equations are obtained for the weft direction by interchanging suffix from 1 to 2 or vice-versa as below:

Also,

d1+d2=h1+h2=D

In all, there are seven equations connecting eleven variables. If any four variables are known then the equations can be solved and the remaining variables can be determined.

The model is not merely an exercise in mathematics. It is not only useful in determining the entire structure of a fabric from a few values given in technological terms but it also establishes a base for calculating various changes in fabric geometry when the fabric is subjected to known extensions in a given direction or known compressions or complete swelling in aqueous medium.

In conclusion, Pierce Geometrical Modeling for plain fabrics is a valuable framework that allows textile engineers, designers, and researchers to gain a deeper understanding of the geometric aspects and structural intricacies of plain woven and knitted fabrics. It enables the precise characterization of thread count, yarn orientation, interlacement patterns, and other critical parameters that influence the fabric’s appearance, behavior, and performance.

By employing mathematical principles and computational tools, Pierce Geometrical Modeling empowers professionals in the textile industry to optimize fabric designs, predict mechanical properties, and develop innovative textiles for a wide range of applications. This approach not only preserves the rich heritage of textile craftsmanship but also propels the industry forward into an era of precision, sustainability, and tailored fabric solutions to meet the diverse needs of today’s world.

Texpedi.com

Check out these related articles: