Md. Bashar Uddin

Lecturer, Department of Yarn Engineering, Bangladesh University of Textiles

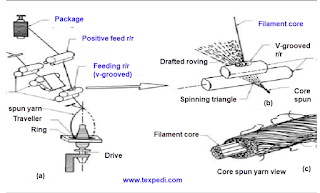

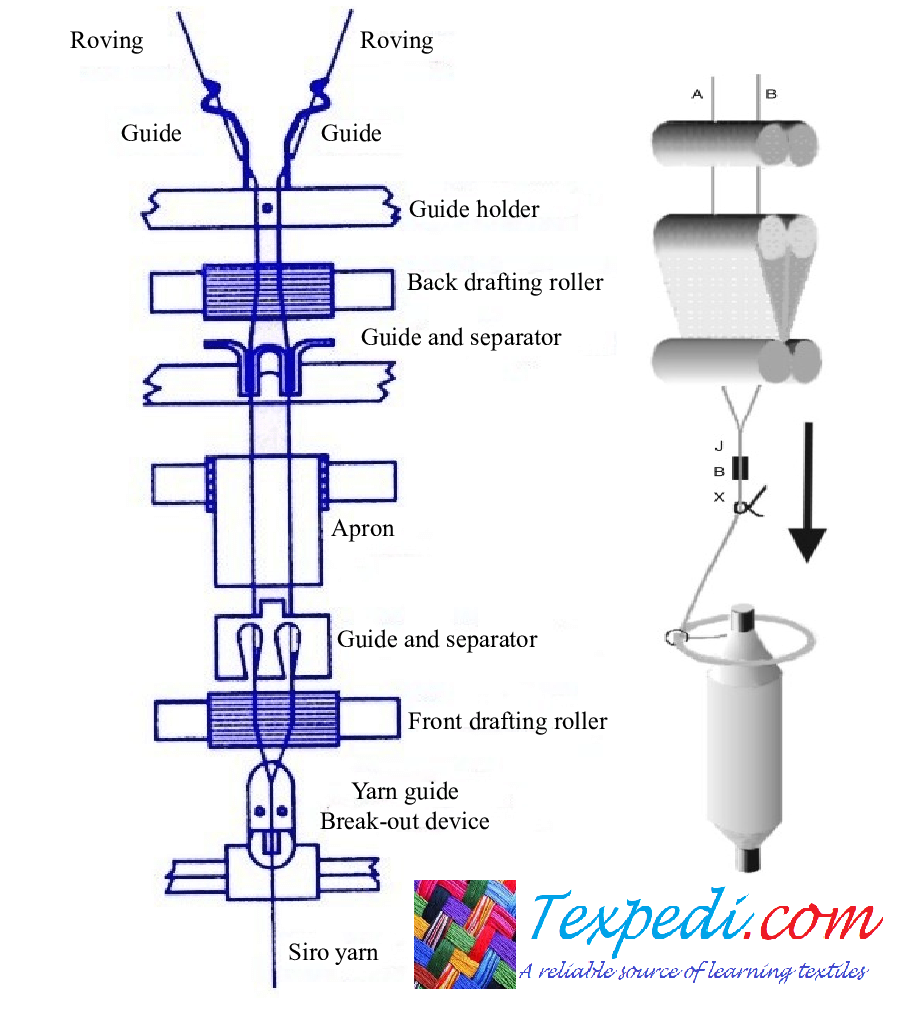

Lycra percentage calculation: Core spinning involves twisting fibers around an existing yarn—filament or staple spun—to create a sheath-core structure. This yarn is produced effectively by most spinning systems, with or without additional attachments.

Core spun yarn

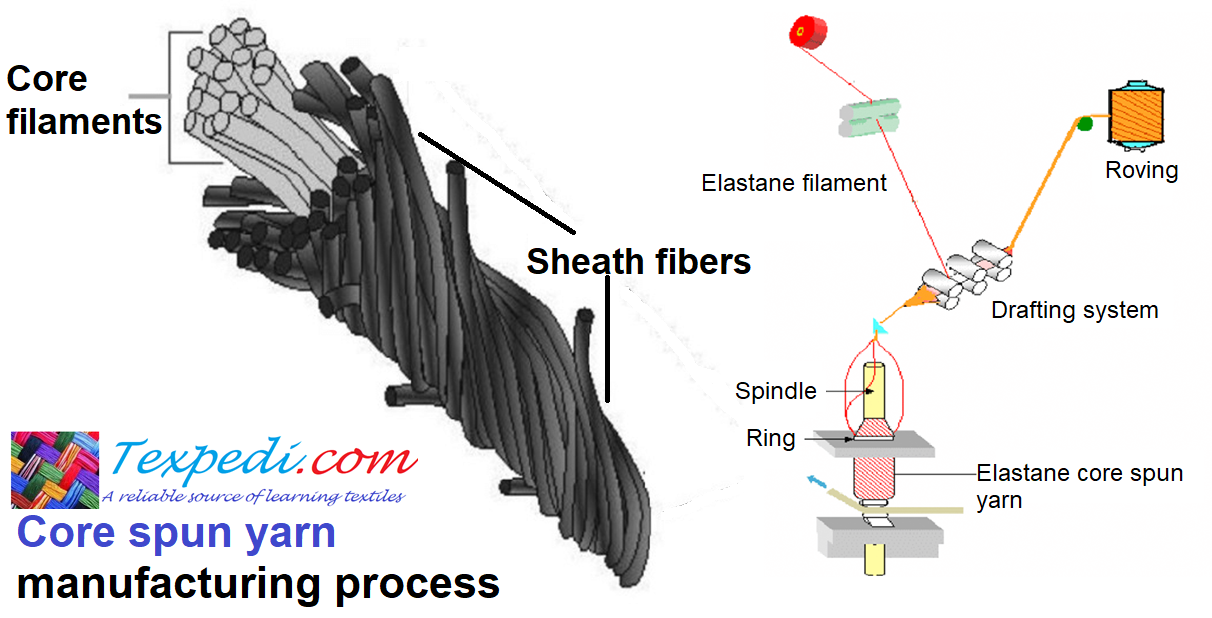

Core spun yarns are two-component structure with Core and sheath. Generally continuous filament yarn is used as core and the staple fibres are used as sheath covering. The core spun yarns are used to enhance functional properties of the fabrics such as strength, durability and stretch comfort.

Incorporating the core part within the resultant yarn structure makes the yarn cheaper, stronger, and qualified. Additionally, sheath fibers conserve the traditional appearance, handle, and comfort properties. It is exemplified by using cotton-covered elastic (spandex/lycra) core-spun yarn, which allows free movements and provides higher fabric comfort with cotton in the yarn structure.

Lycra percentage calculation

Elastane/Spandex/Lycra | Lycra is a product of DuPont for spandex fiber. Additionally, it’s a polyether-polyurea copolymer invented in 1958 by chemist Joseph Shivers at DuPont’s Benger Laboratory in Waynesboro, Virginia. Furthermore, Lycra® is a trademark and brand name of the DuPont Company. Altogether, spandex is synonymous with elastane fiber. Spandex or elastane specify properties of fiber (rubber like stretchable) those are used in skin tight clothes such as swimsuits, jeans, sports wears etc. There are other companies who also manufacture spandex fibers. So, there is no technical difference in between Lycra and Spandex. Both Lycra and Spandex are same. Spandex is the generic name of a fiber and Lycra is spandex product of DuPont company.

Elastic core spun yarn

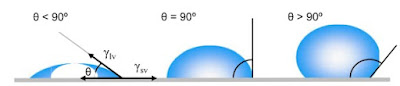

Elastic core spun yarn which is used as weft yarn for textile fabrics (e.g. denim) gained great importance in the last decade due to the fact that stretch and recovery, comfort fits and flexibility properties. Elasticity, above all, the spandex/ lycra percentage calculation, substantially influences the physical, dimensional, and mechanical properties of end products. Additionally, fabric characteristics vary according to the elastane (spandex) percentages in the yarn. Therefore, it’s essential to explore the calculation procedure for lycra percentages in core-spun yarn.

Example: We want to produce a 50 Ne elastic core spun yarn. To create the elastic core spun yarn, we’ll use lycra as the core and cotton as the sheath material. Above all, lycra has a linear density of 70 Denier and a tension draft of 3.25. After that, we must calculate the percentages of lycra and cotton in the resulting yarn.

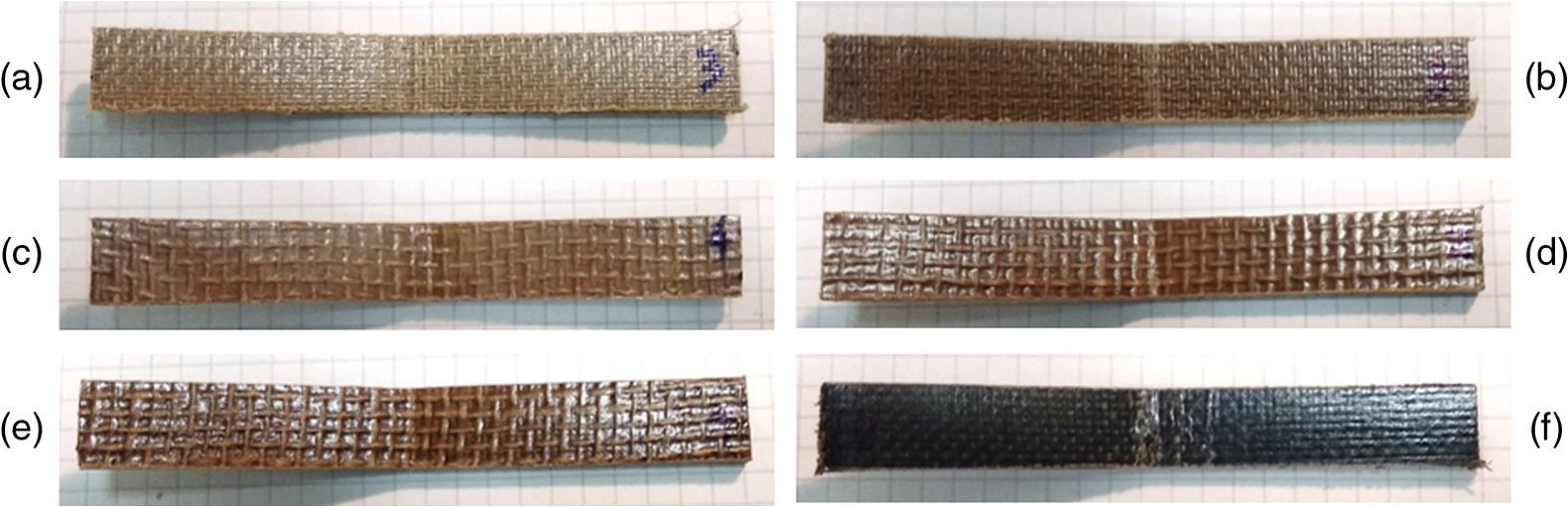

|

| Structure of an elastic core spun yarn |

Solution:

>>Cotton Covered Lycra Yarn (Elastic Core Spun Yarn), Resultant Yarn (N)= 50 Ne = 5314.9÷50= 106.298 D.

>Input Lycra filament= 70 D.

>Lycra tension draft= 3.25

We know, Draft= Input Count (Den)/Output Count (Den)

>Lycra count in output (Resultant Yarn), N1= Input lycra filament count÷Lycra tension draft.

>N1= 70÷3.25= 21.538 D.

>> Lycra count in output (Resultant Yarn), N1= 21.538 D.

Again, we know, N= N1 + N2 (Direct System)

>>106.298= 21.538+N2

>>N2= 106.298-21.538= 84.760 D.

>>Cotton yarn count in output (Resultant Yarn), N2= 84.760 D.

>>Lycra% in Resultant Yarn (Core Spun Yarn) = [21.538/(21.538+84.760)]×100%= 20.26%

>>Cotton% in Resultant Yarn (Core Spun Yarn) = [84.760/(21.538+84.760)]×100%= 79.74%

Or,

Cotton Covered Lycra Yarn (Elastic Core Spun Yarn), Resultant Yarn (N)= 50 Ne.

Input Lycra filament= 70 D = (5314.9÷70) = 75.927 Ne.

>Lycra tension draft= 3.25

We know, Draft= Output Count (Ne)/Input Count (Ne)

>Lycra count in output (Resultant Yarn), N1= Lycra tension draft × Input lycra filament count.

>N1= (3.25×75.927) Ne = 246.763 Ne= (5314.9÷246.763) = 21.538 D.

Again, we know, 1/N = 1/N1 + 1/N2 (Indirect System)

>> (1/50) = (1/246.763) + (1/N2)

>>Cotton yarn count in output (Resultant Yarn), N2= 62.705 Ne.= (5314.9÷62.705)= 84.760 D.

>>Lycra% in Resultant Yarn (Core Spun Yarn)=[21.538/(21.538+84.760)]×100%= 20.26%

>>Cotton% in Resultant Yarn (Core Spun Yarn)= [84.760/(21.538+84.760)]×100%= 79.74%.

Shortcut Method:

1. Lycra%= [(Lycra denier/lycra draft)/Resultant yarn denier] × 100%

2. Lycra%= [(Lycra denier/lycra draft)/5314.9/Resultant yarn Ne] × 100%

3. Lycra%= [(yarn count (Ne) × lycra denier)/(5314.9 × lycra draft)] × 100℅.

References

1.https://www.fibre2fashion.com/industry-article/1764/production-and-properties-of-core spun-yarns

2. Balasubramaniam, Properties of core spun yarns-Journal of Textile Institute T534-61-1970

3.https://www.onlineclothingstudy.com/2013/06/what-is-difference-between-lycra-and.html?m=1

4. https://en.m.wikipedia.org/wiki/Spandex.

Texpedi.com

Check out these related articles:

I appreciate this writing, dear basar sir. very useful information to find out Spandex percentage

This is really nice post.