Different spinning methods

Ring spinning method👇

A process of spinning in which the yarn is twisted and drawn while passing through a small metal device travelling rapidly around a ring in the operation of winding the yarn onto a bobbin.

Rotor spinning method👇

A type of open-end spinning, in which fibres are detached from the card sliver and twisted, within a rotor, as they are joined to the end of the yarn.

Air-jet spinning method👇

Is a pneumatic method which consists of passing a drafted strand of fibres through one or two fluid nozzles located between the front roller of a drafting system and a take up a device. This process employs an air-jet to rotate the fibre strands and twist them into a yarn.

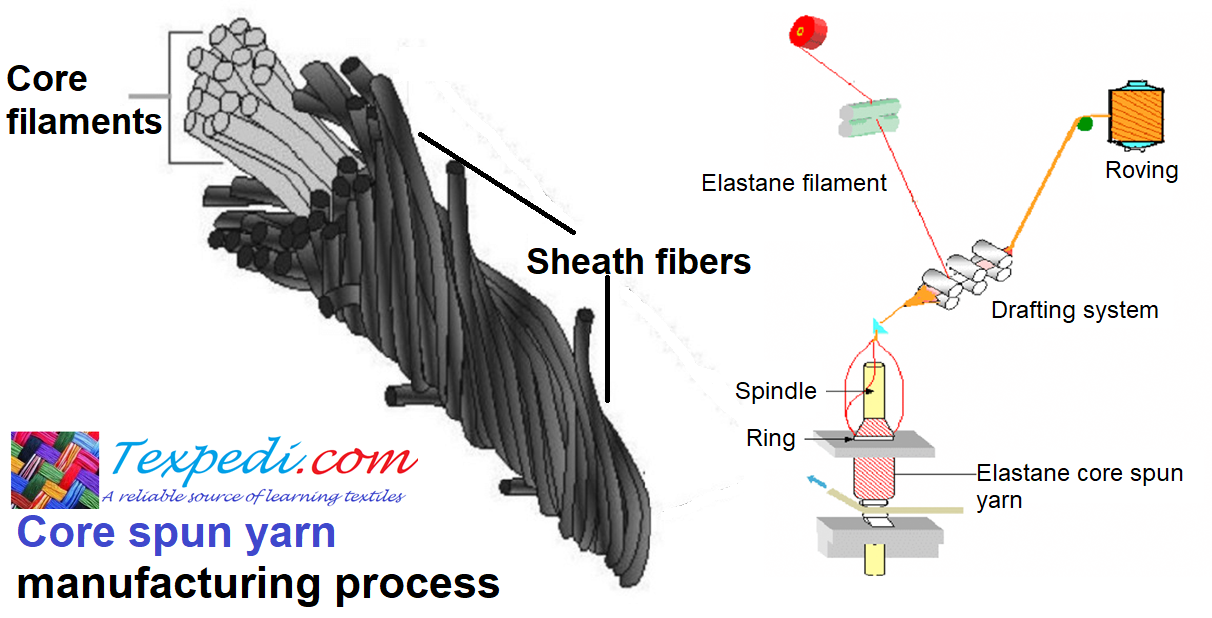

Friction spinning method👇

Is an ‘open-end’ or a ‘core-type’ form of spinning (or both), in which the yarn formation takes place with the aid of frictional forces in the spinning zone. Friction- spun yarns are characterized by a distinct wrapper surface.

Characteristics of different spinning methods

Spinning methods | Actual twist –insertion rate per minute | System limited by | Delivery speed (m/min) | |

| Twist-insertion rate | Drafting & fibre transport speed | |||

| Ring | 15,000 – 25, 000 | Yes | No | 20 – 30 |

| Rotor | 80,000 – 150,000 | Yes | Partly | 100 – 300 |

| Air-jet | 150,000 – 250,000 | No | Yes | 150 – 450 |

Friction | 200,000 – 300,000 | No | Yes | 150 – 400 |

Fibre properties affecting spinning methods

| Order of importance | Ring | Rotor | Air-jet | Friction |

| 1 | Length & length uniformity | Strength | Fineness | Strength |

| 2 | Strength | Fineness | Cleanliness | Fineness |

| 3 | Fineness | Length & length Uniformity | Strength | Length & length uniformity |

| 4 |

|

| Length & length uniformity | Cleanliness |

What are the major differences between carded and combed yarn?

The yarn that is obtained without going through the combing operation is called carded yarn while the yarn that is obtained by combing is called combed yarn. There is a significant quality difference between these two types of yarn. The most prominent differences are as below-

| Carded yarn | Combed Yarn |

| 1. Carded yarns are produced including short fibres. | 1. Combed yarns are produced excluding short fibres. |

| 2. Comparatively less regular yarn. | 2. More regular yarn. |

| 3. Comparatively lower strength of the yarn. | 3. Comparatively higher breaking strength. |

| 4. Less lustrous. | 4. More lustrous. |

| 5. Less costly. | 5. More costly. |

| 6. Contain neps. | 6. No neps. |

| 7. More hairy. | 7. Less hairy. |

| 8. Lower quality of yarn. | 8. Higher quality of yarn. |

| 9. Short fibre% is high. | 9. Short fibre% is low. |

What is a special yarn?

Special yarns are those yarns, in which some deliberate fancy properties are incorporated. A yarn with specific or special effects & properties which differ from normal or standard yarn in respect to strength, appearance, elasticity, surface effects, elongation, colour etc.

👉Melange yarn

Melange yarn is a blended yarn spun from the blending of two fibres – cotton and dyed viscose. There are two types of melange yarn on the basis of the amount of dyed viscose fibre.

i. Grey Melange: When in yarn up to 15% wt is dyed viscose.

ii. Ecru Melange: When in yarn more than 15% wt in dyed viscose.

👉Slub Yarn

Slub yarn is a yarn containing irregularity & varying thickness along yarn length, which obtained by making the bottom roller on the spinning frame for working at a different speed.

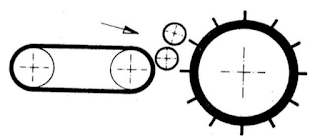

👉Core Spun Yarn

Core yarn is called composite, mixed or blend yarn consists of two or more types of filament in which one yarn or few filaments in the centre covering with natural or synthetic staple fibres.

👉T400 Yarn

Elasto-multiester is mainly used in woven fabrics, usually on the weft, in a quantity higher than 20% by weight. It is used as an alternative to elastane to give elastic properties to the final product. T400 fibre allows us to improve the performance of cotton fabrics to enhance comfort, shape retention and durability.

👉Others

Spiral or corkscrew yarns, chenille yarn, ribbon yarns, tape yarn, Knop yarn etc.

Different types of wastes in a spin line with their percentage

Various amount of wastages has been seen during producing yarn in spinning. But it varies from carded yarn to combed yarn. Carded yarn produces 10 – 12 % waste and Combed yarn produce 20 – 25 % waste in a spin line. Average waste percentages of different operations in the spin-line have been mentioned below-

| Yarn manufacturing process | waste% |

| Blow room | 3-4% |

| Carding | 4-5% |

| Drawing | 0.5-1% |

| Comber | 10-20% |

| Simplex | 0.5-1% |

| Ring Frame | 2-3% |

| Winding | 1-2% |

Author courtesy:

Engr. Sharif Ahmed

Assistant Professor

Department of Yarn Engineering

Bangladesh University of Textiles

Texpedi.com

Check out these related articles: