Most of the fabric type is applicable to create a major lot of apparel. Among those fabric types, core spun yarn (CSY) is one of them. These yarns are a fabric type that requires to get made by wrapping a staple polyester around a non-filament polyester fiber during the spinning process. In the apparel industry, CSY comes with many uses. This article will take you into the details of the applicability of CSYs with various advantages in short.

What is Core Spun Yarn?

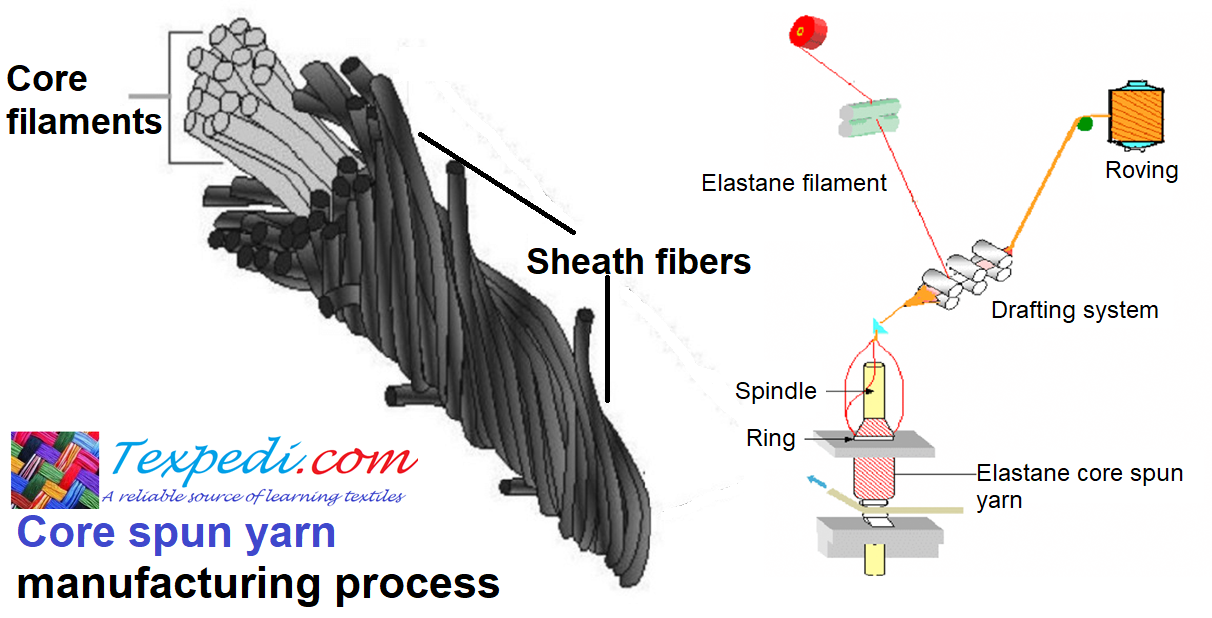

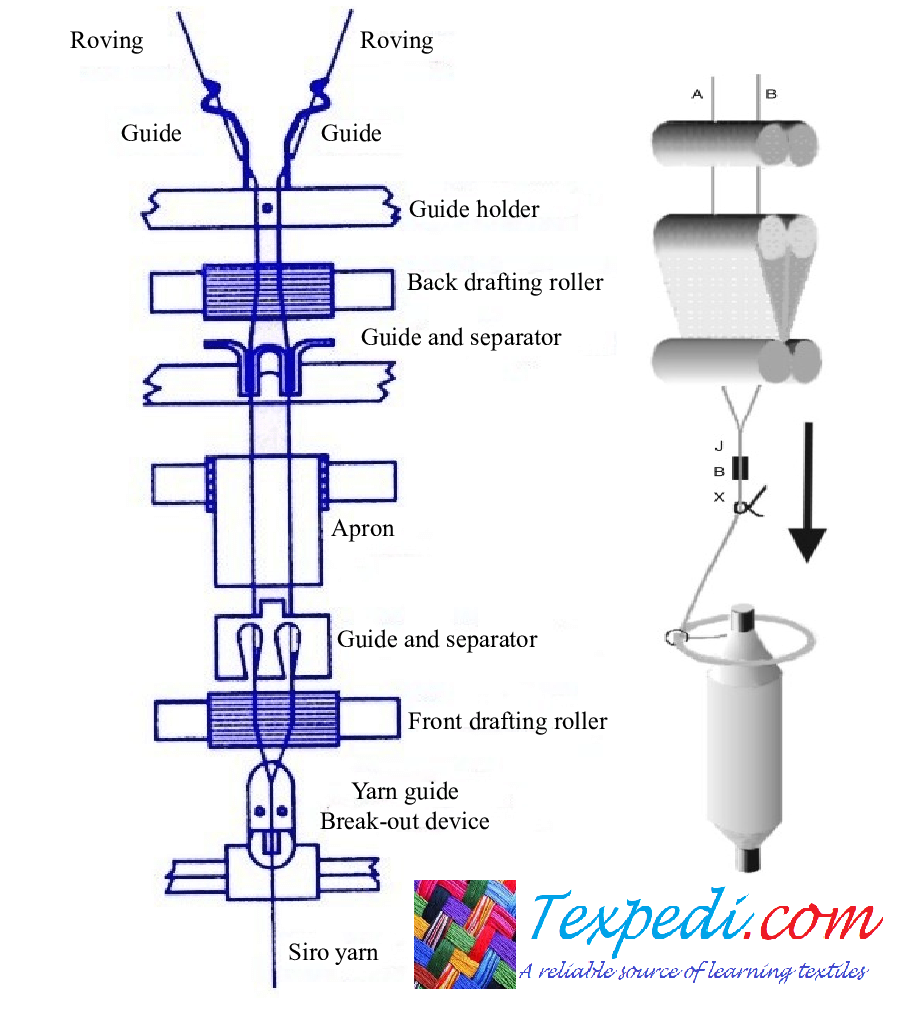

Core spun yarns refer to the dual-component structure including the core and the sheath. The yarn filament has the application of being the core and the staple fibers work to cover the sheath. CSY gets made by utilizing the 100% of Polyester staple fibers. Meanwhile, Dual-core spun yarns are changeable when going into a ring-spinning gadget. CSY has another name ‘Polycore’. Here, the yarn gets generated around a core-like material by twisting the staple fibers. In most cases, CSY comes as a cotton core. The properties of CSY are many in nature. For instances:

| Yarn name | Core spun yarn |

|---|---|

| Tenacity level | High (Higher strength in each length) |

| Abrasion and Fire resistance ability | Superior |

| Ply security ability | Better |

| Durability | Durable |

Core spun yarn constructions?

Core spun yarn is a textile innovation that has revolutionized the world of yarn construction. This specialized yarn is created by wrapping staple fibers around a central core, typically made of a different material. The core acts as the foundation, providing strength and stability, while the outer layer of spun fibers contributes to the yarn’s appearance, texture, and performance characteristics. The choice of materials for the core and the outer layer can vary widely, depending on the desired properties of the final yarn.

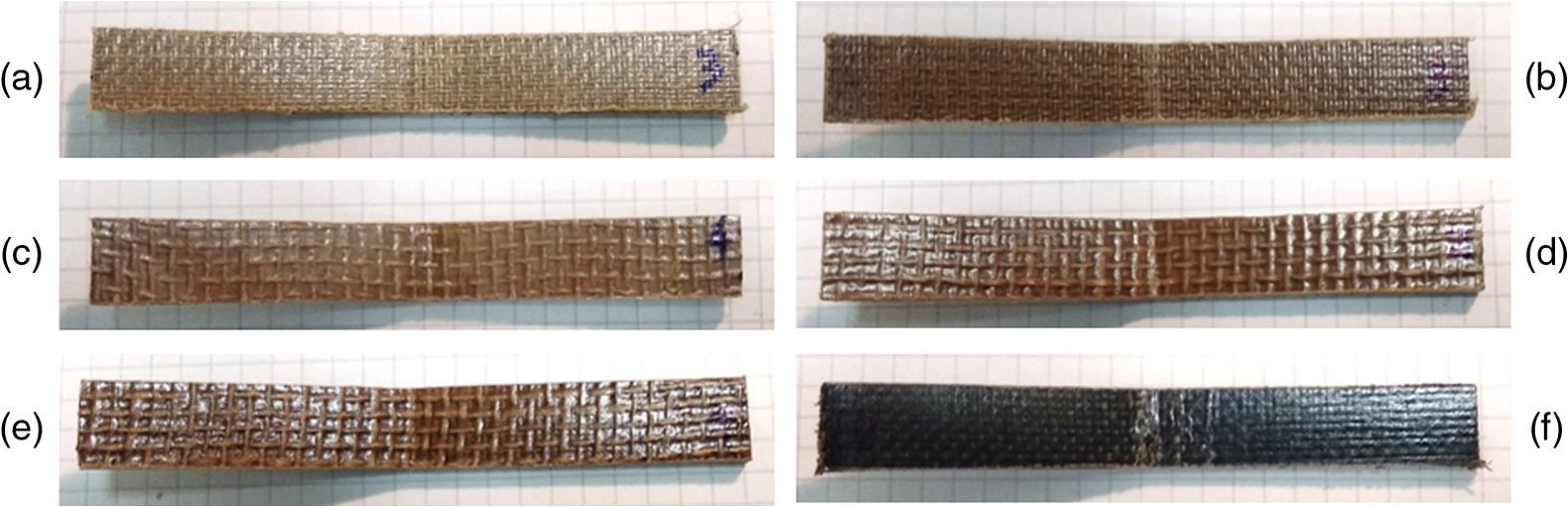

For instance, a common application is to use a strong and durable core, such as polyester or nylon, with a softer and more comfortable outer layer made of cotton or wool. This combination allows for the best of both worlds, blending the core’s strength with the outer layer’s desirable texture and feel. Core spun yarns find applications in various industries, from textiles and fashion to technical textiles and outdoor gear, where their unique construction and compositions enable the creation of high-performance and versatile fabrics and products.

Core Spun Yarn Examples?

CSY comes in different types which are mostly get used in industrial sewing. Because of the better stretchability, the CSY offers the following types: Cotton core spun, Tri-blend, Slub, 100% Polyester, Poly Cotton, Modal and Tencel.

Core spun yarn is a versatile type of yarn that combines a central core with an outer layer of spun fibers. The choice of materials for the core and outer layer can vary, resulting in a wide range of core spun yarn examples tailored for different purposes. Here are a few examples:

- Cotton-Wrapped Polyester Core Spun Yarn: In this example, a strong polyester core is wrapped with soft cotton fibers on the outside. This blend offers the durability of polyester with the comfort and breathability of cotton, making it suitable for various applications in the textile and apparel industry.

- Nylon-Wrapped Lycra Core Spun Yarn: Lycra (or spandex) is often used as the core in this type of yarn. The stretchy properties of Lycra combined with the strength of nylon create a flexible and resilient yarn commonly used in stretch fabrics, sportswear, and activewear.

- Wool-Wrapped Elastic Core Spun Yarn: Elastic core spun yarns feature an elastic core, typically made of rubber or elastane, surrounded by a layer of natural or synthetic fibers like wool. These yarns are used in knitting socks, gloves, and other items requiring elasticity and comfort.

- Nomex-Wrapped Kevlar Core Spun Yarn: For specialized applications like protective clothing and industrial textiles, Kevlar is used as the core material, providing high tensile strength and flame resistance, while Nomex fibers form the outer layer, offering heat resistance and comfort.

- Polyester-Wrapped Stainless Steel Core Spun Yarn: In situations demanding conductivity and durability, stainless steel wires are used as the core, and polyester fibers are spun around them. This combination is employed in applications like anti-static clothing and technical textiles.

These examples showcase the diversity of core spun yarns, each designed to meet specific performance and functional requirements in various industries, from fashion to industrial and technical textiles.

What is the Use of Core Spun Yarn: Applications?

Core spun yarn comes in a cotton type which is also known as skin polyester. In this cotton CSY, the core is used in a wide sphere. For instance, cotton CSY helps to produce student clothes, fabrics, quit sheets, and decorative items. Meanwhile, Polyester CSY is a popular viscose fiber-covered thing. Cotton silk or cotton wool-covered CSYs also greatly value the apparel market.

Application Areas of Core Spun Yarns?

- Clothing fabric

- Elastic fabric

- Decorative fabric

- Sewing thread

Being the finest fabric out there, CSY possesses exciting properties that make it a perfect deal to use the fabric in the denim version.

Core Spun Yarn as Threads in the Application Area

The application areas of CSYs are leather products as well as bed mattresses, and quilts. Also, there are women’s shoes and handbags. CSY is also applicable for making rice bags for immense strength and durability.

Choosing the right sewing thread is necessary. All you must do is-

- To keep in mind the upholstery strength

- To buy the thread

- To choose the multi-purpose polyester threads

- To check whether threads are compatible with the fabric’s structure

- To check the thread color

Advantages of Core Spun Yarn

From producing new products to applying easy-washing methods, Core-spun yarn offers several advantages. The advantages are given below separately in points:

- Introducing newer products: The ring spinning method helps the CSY to produce better products to keep the development running in the textile manufacturing industry.

- Performance Level is high: CSY possesses exceptional durability and strength that leads the performance level to be the highest.

- Easy-to-Wash Advantage: The core-spun yarn-made products are easily wearable and easy to wash.

- Higher Strength: CSY strength up to 40 to 50% including the polyester threads of the same size.

- Sew ability is superior: On both manual and automatic machines, core-spun yarn requires minimum interruptions with fewer restitched seams.

- Minimizing Seams: It helps to reduce the open seams and their failure. Also, minimizing broken and cut stitching is easier.

Conclusion

Core spun yarn has the applicability mostly on the enhancement of the fabric’s functional properties. For instance, stretch, durability, and strength. Fabric comfort is one of the criteria to put CSY together. Core-spun yarn manufacturing is possible by integrating and combining the different filament packages of the ring shape. Apart from its expensive cost, CSY can increase the cost of production and performance level.

Texpedi.com

Check out these related articles:

Thank you very much for your appreciation. Stay tuned. If you find our site informative, please share our site with your friends and family.

It’s really a cool and helpful piece of info. I am satisfied that you just shared this

useful info with us. Please keep us up to date like

this. Thank you for sharing.