Interlining?

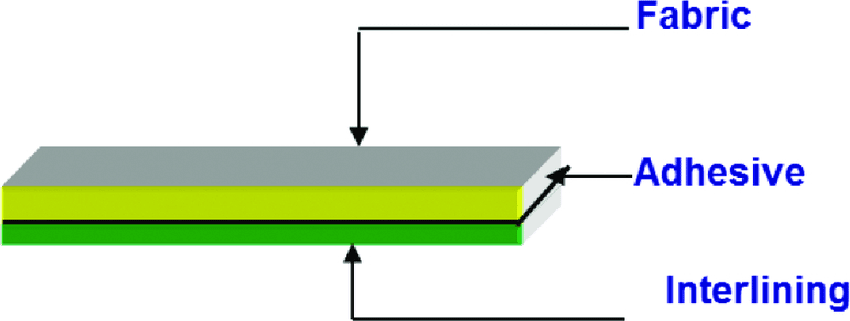

Interlining is a sheet of fusible or non-fusible material that is used in-between the layers of fabric to give a certain shape and strength. For example, interlining is used in the collars, cuffs, waistbands to ensure the shape. Right interlining should be carefully selected to avoid any types of damage to the garments/parts of the garments. Interlining may be introduced to the garment parts either by sewing or fusing depending on the types of interlining being used.

Interlinings are the accessories used between two layers of fabric to keep the different components of apparel in the desired shape or to improve the aesthetics and/or performance. Generally, interlinings are soft, thick, and flexible fabric made of cotton, nylon, polyester, wool and viscose or their blends, which may be coated with some resins.

How many types of interlining are used in garments?

1. Sewn Interlining or Non-Fusible Interlining.

2. Fusible Interlining:

- PVC coated interlining,

- PVA coated interlining,

- Polyethene coated interlining,

- Polyester coated interlining,

- Polyamide coated interlining,

- Polypropylene coated interlining.

Texpedi.com

Check out these related articles: