There are different types of roller used in the blow room line which have been mentioned below-

1. Spiked Roller / Rollers with teeth or blades or Spikes:

– Flat, oval or round bars are welded, riveted or screwed to closed cylinders.

– Used in Modern Horizontal Cleaners, Chute feeds, mixing bale opener, step cleaner etc.

– The rollers rotate at speeds in the range 600-1000 rpm.

– The bladed drum is used in Porcupine opener.

|

| Spiked rollers |

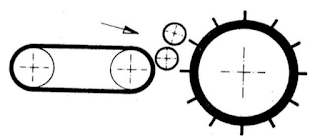

2. Drums with teeth or spikes:

– Same as rollers but larger diameters of 600 mm and more.

– When the drum is designed for use at the start of the process, the spacing of the striker elements on the drums is coarse and fine when the drum is designed for use in the middle or towards the end of the line (for example porcupine cleaner)

– Rotates vary between 400-800 rpm

– Parallel, on right-angled, arrange the device to the material flow.

|

| Drum with teeth or spikes |

3.Rollers with toothed discs:

– It is made up of many toothed discs secured to a shaft with an appropriate number of distance pieces.

– The teeth are almost always asymmetrically formed since they have to operate in only one direction.

– Rollers with toothed discs belong to the middle of the blow room line.

|

| Roller with toothed discs |

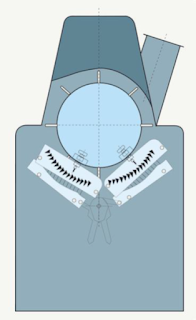

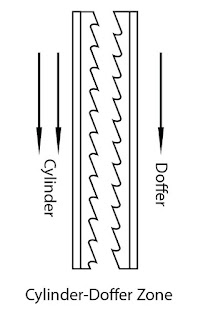

4. Carding roller:

– A saw-toothed wire is used.

– Gives first opening and best cleaning action but creates stress on fibres.

– Rotational speeds lie between 600 to 1000 RPM

– Carding roller is used at the end of blow room line.

|

| Carding roller |

5. Rollers with pinned bars/ Kirschner roller:

– Simple in design.

– Gives favourable flow of fibres.

– Operates like Kirschner beaters.

|

| Roller with pinned bar/Kirschner roller |

Check out these related articles: