- Lower yarn sensor

- Gripper arm tube with shutter

- Electromagnetic yarn tension sensor

- Yarn splicer

- Electronic yarn clearer

- Yarn Tension Regulator Autotense FX*

- Waxing device with wax-roll monitoring*

- Yarn trap

- Suction tube with upper yarn sensor

- Winding unit control system

- Propack FX*

- Variopack FX*

- Operating and display elements

- Drum lap guard

- Yarn guide drum with Auto Torque Transmission (ATT)

- Package cradle with weight compensation *optional extra

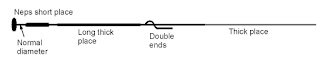

- Neps,

- Short thick places,

- Long thick places

- Double ends / spinner’s doubles and

- Thin places

👉Neps – Neps are defects that are extremely short (no larger than few mm) and extremely thick in multiples of normal yarn diameter.

👉Short places – Short places are defects of limited length and of substantial thickness/ cross-sectional increase.

👉Long places, double ends and spinner’s doubles – Long places are defects of substantially longer lengths with marginal increase in yarn diameter/ cross-sectional area. Double ends are caused by two ends being pulled off simultaneously while spinner’s doubles are caused by two rovings spun together. These defects are extremely long.

👉Thin places – Thin places are defects of substantially longer lengths with decrease in yarn diameter/ cross-sectional area.

In setting panel of an electronic yarn clearer, the user has to input values of sets of diameter and length that shapes clearing curve in particular region to selectively eliminate particular category of yarn faults.

What is yarn splicing?

Yarn splicing is a process of overlapping two ends of yarn. Yarn breakage during the yarn winding process is the situation to make the yarn splicing.

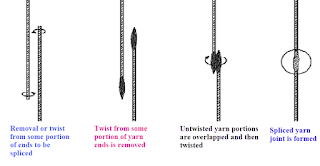

Stages of splicing a spun yarn: Spun yarn splicing involves three stage:

- First stage consists of removal of twist from some length of yarn ends to be spliced. This operation is called untwisting or opening.

- After removing twist, the opened yarn portions are overlapped on each other.

- Subsequently, the untwisted overlapped ends are twisted to rejoin the yarn ends.

Check out these related articles: