Md. Reajul Islam

PhD Candidate (Textile Engineering), Çukurova University, Turkey and Assistant Professor (Study Leave); Department of Yarn Engineering, BUTEX

Introduction

PhD Candidate (Textile Engineering), Çukurova University, Turkey and Assistant Professor (Study Leave); Department of Yarn Engineering, BUTEX

Introduction

Fibre from the industrial hemp plant is one of nature’s wonders – it is used in everything from stuffing furnishings to high-quality textiles. Hemp is a bast fibre extracted from the stalk of hemp plants that grow well in the soils, which are well-drained, rich in nitrogen, and nonacidic. Hemp is called a fibre of a hundred uses. True hemp is a fine, light-coloured, lustrous, and strong bast fibre, obtained from the hemp plant, “cannabis Sativa.” The bark of the hemp stalk contains bast fibres, which are among the earth’s longest natural soft fibres and rich in cellulose.

Chemical composition

Composition |

Hemp |

Cotton |

Cellulose |

60 – 70% |

88 – 95 % |

Hemicellulose |

15 – 20% |

——– |

Lignin |

2 – 4% |

——— |

Pectin |

2 – 4% |

0.7 – 1.2% |

Oil and wax |

1- 2% |

0.5% |

Proteins, pectose and colouring matter |

——— |

1- 2% |

Comparative chemical composition (%) of bast fibres

Fibrous material |

Cellulose |

Hemicellulose |

Lignin* |

Flax |

62 – 71 |

16 – 18 |

2.0 –2.5* |

Hemp |

67-75 |

16 – 18 |

2.9 –3.3* |

Jute |

59 – 71 |

12 – 13 |

11.8–12.9* |

Kenaf |

65 |

13 |

21.6* |

* The higher the lignin percentage, the lower the quality.

Production of hemp fiber

There are three main stages of producing fiber from industrial hemp –

1. Harvesting

2. Retting

3. Separation

Harvesting: The quality of hemp fibre depends greatly on whether the crop was grown primarily for (i) Textile use or (ii) Dual purpose. A crop grown specifically for textile fibre will generally produce a higher quality product than a dual-use crop. Dual-purpose crops produce fiber and seed; with the seed being used for food and biofuels and other applications.

Retting: Retting is a process involving the use of moisture and microbes to break down the chemical bonds (pectin) holding the hemp stem together, enabling easier separation of the bast from the woody core (the hurd or shiv). In practice hemp stems may be retted in several methods:

- Field, dew retted

- Water retted

- Enzyme retted

- Chemical retted

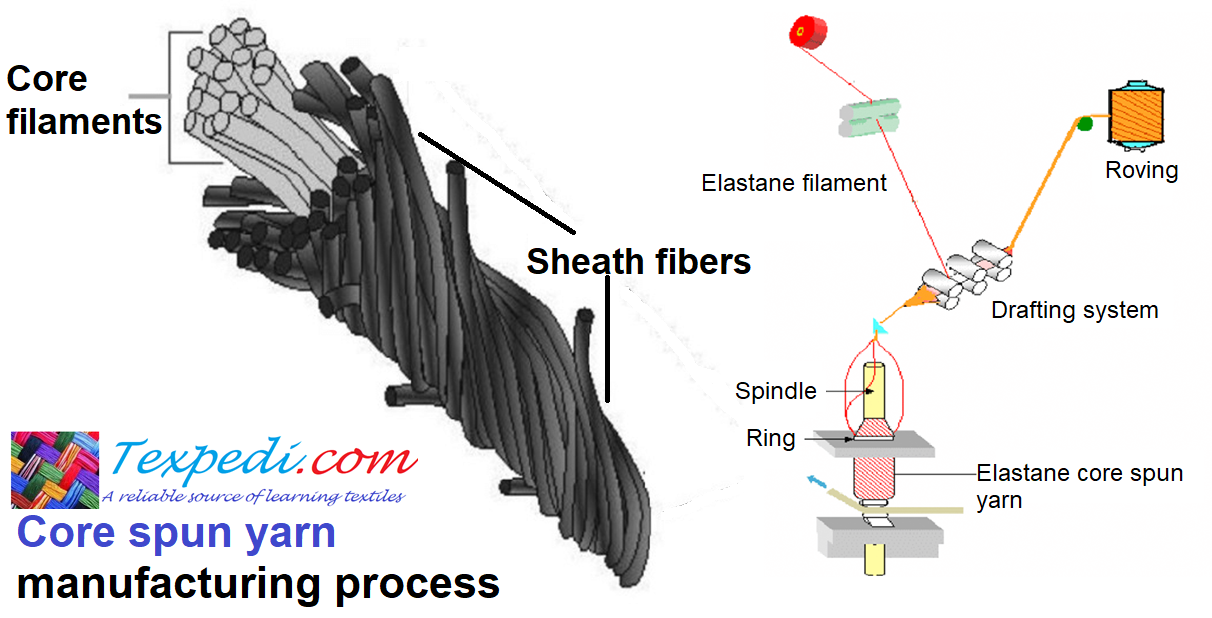

Fiber separation: In a process called “breaking”, stalks are passed between fluted rollers to crush and break the hurd into small pieces, separating some of the fibre in the process. A further process called “scutching” beats and scrapes the fiber bundles, separating more short fiber and the remaining hurd material from the long fiber.

Types of Hemp Fiber

1. Tow

2. Line

The short fibers produced during the separation process are known as tow and the long fibers are called line fibre. Line fiber can be incredibly long – depending on the height of the plant, a single strand may be up to 5 metres in length. Hemp tow is used for stuffing or coarse yarn spinning. Line fibre for higher-end applications such as clothing fabrics, furnishing and floor coverings.

Physical Properties of Hemp Fiber

- Colour: From yellowish-grey to deep brown.

- Length: 4–6.5 feet.

- Tensile Strength: A very strong fiber (250 MPa for 66 µm).

- Elongation at break: Hemp fibers stress easily.

- Elastic recovery: Elastic recovery is very poor, even less than linen fiber.

- Moisture regain: 12 %.

- Effect of heat: Excellent resistance to thermal degradation.

- Effect of sunlight: Sufficient resistance against sunlight.

- Lustre: Highly bright similar to linen fiber.

Chemical Properties of Hemp Fiber

- Effect of acids: Similar to the cotton fiber, hemp is attacked and disintegrated by hot dilute acids or cold concentrated acids.

- Effect of alkalis: Has excellent alkali resistance.

- Effect of organic solvent: Resistant against organic solvents.

- Effect of insects: Resistant against moth-grubs or beetles.

What is sustainability?

Sustainability in textiles is just as multi-dimensional. While many have described parts of it, few have captured it totally. Some interchangeable and widely used terms for sustainability are:

- Ethical manufacturing/business

- Green manufacturing

- Organically manufacturing

Impact of Production Process of Hemp Fiber on Sustainability

Hemp nuts used in modern hemp-based products (e.g., TemptHemp) are pesticide and herbicide-free. Hemp plants do not lead to depletion of soil, unlike many industrial crops. Enrichment of soils occurs due to hemp plants as they throw out their leaves to soils throughout the whole growing season and thereby produce a mature compost. This leads to the enrichment of soils as well as retention of soil moisture, also due to the fact that hemp requires only 50 % of the water used by other agricultural crops. Besides,

- Hemp plants help to maintain a strong soil structure and therefore, protect soils from runoff due to their deep roots of at least three feet under the ground.

- Hemp cultivation removes heavy metals from soils leading to soil purification.

- Hemp acts as a carbon sink due to absorption of CO2

- Hemp fibre production is an efficient process; it is possible to get 250 % more fibre than cotton and 600 % more fibre than flax per acre.

Diversified uses of Hemp

👉The inner core is used in animal bedding or construction material while the outer bast fibres are applicable for use in high-quality papers, insulation material, biocomposites, ropes and textiles depending on the quality and processing. (Piotrowski & Carus 2010).

👉The majority of the seeds is used in food or pressed into oil or in cosmetics. (Carus et al. 2013).

👉In 2008, 26 million tons of natural fibres were used for industrial purposes. The majority of this was cotton (86%). Jute, kenaf, hemp and flax form only a minority. (Raschka & Carus 2012).

👉These fibres are interchangeable in composite materials and are often used in blends. (Bouloc et al. 2013).

|

| Diversified uses of Hemp Fiber |

👉Hemp fibres for paper production can be of lowest purity, still containing the largest percentage of shivs. It is used in speciality papers, like cigarette paper. (Snauwaert & Ghekiere 2011).

👉Especially with shortages and sustainability issues of forest resources, non-wood pulp sources may gain importance in the future. (González-García et al. 2010).

👉Hemp would have a serious growth potential in insulation materials as a sustainable alternative to mineral and glass wool if production costs could be reduced. (Carus et al. 2013).

👉In composite materials, hemp fibre can replace glass fibres to reinforce plastics. These so-called biocomposites are lighter but as strong as traditional composites used in the automotive industry. (Piotrowski & Carus 2010).

👉Hemp plastic is an affordable bio-based natural fibre composite to replace oil-based raw materials.

👉Hemp plastics can be five times stiffer and two and a half times stronger than polypropylene.

👉Hemp is already being used in compressed door panels and Dashboards.

👉Carmakers such as Ford, GM, Chrysler, Saturn, BMW, Honda, and Mercedes are currently using hemp composite door panels, trunks, headliners, etc.

Is Hemp Legal?

Hemp has been misunderstood and miscategorized for most of the 20th century. Hemp has received a bad reputation and been classified as a drug along with Marijuana. Hemp cultivation had been prohibited in the United States and Canada since the 1937s as part of controls on the recreational use of cannabinoids. Even though hemp is in the cannabis (Cannabis Sativa L) family, the main difference between the two cannabis plants is that hemp has very little THC (tetrahydrocannabinol), less than .03% of the psychoactive ingredient. Additional research on the crops various properties began changing the global perception of hemp in the 1990s. Canada eventually legalized production in 1998, marking the beginning of hemp cultivation across the country. The USA legalized hemp production in 2018.

Conclusion

During the past three decades, cotton started to draw serious attention from the environmentalist corner. Now it is assumed that cotton is not a sustainable crop at all. Hemp and cotton could be substitutable products. Additional research is necessary to determine if consumers perceive the wear and care characteristics of hemp and cotton as substitutable. On the other hand, Hemp has diversified use and holds the key to a sustainable future.

References

1. Roadmap to Sustainable Textiles and Clothing (Eco-friendly Raw Materials, Technologies, and Processing Methods)

2. Sustainable textiles (life cycles and environmental impact)

3. Hand book of natural fibers. (Bast fibres: hemp cultivation and production) M. R. L. HORNE, De Montfort University, UK

4. Piotrowski, S. & Carus, M., 2011. Ecological benefits of hemp and flax cultivation and products. Nova-Institute, Hürth.

5. Piotrowski, S. & Carus, M., 2010. Natural fibres in technical applications: market and trends Mussig (2010).

6. Carus, M., Karst, S., Kauffmann, A., Hobson, J. & Bertucelli, S., 2013. The European Hemp Industry: cultivation, processing and applications for fibres, shivs and seeds. European Industrial Hemp Association, Hürth.

7. www. Hempgazette.com

8. nationalhempassociation.org

9. textiletoday.com.bd/extraction-processing-properties-and-use-of-hemp-fiber/

10. https://nptel.ac.in/courses/116102026/15

11. www. en.wikipedia.org

12. http://textilefocus.com/sustainability-textile-industry-reality- challenges/

13. Report of the World Commission on Environment and Development (WCED)

Texpedi.com

Check out these related articles: