Engr. Fahad Mahmud

Lecturer (Technical), Department of textiles at SKTEC

The terms procurement and purchasing are often used interchangeably; however, there are important similarities and differences between them. This certification track employs the following definitions for each term:

Purchasing is a function within the procurement process that is largely transactional and associated with how goods and services are ordered. Purchasing involves receiving and processing purchase requisitions (requirements) and converting them to purchase orders (POs) (awards to suppliers).

A Procurement Example

|

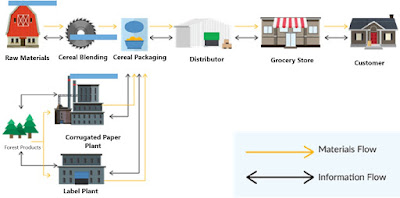

| Figure: Blue text items indicate procurement focus in a cereal manufacturing and distribution process. Developed by LINCS in Supply Chain Management Consortium. |

The above figure shows an example of a cereal manufacturing and supply chain process and the key role that procurement plays to purchase grain and other raw materials, along with packaging and labelling products needed to make breakfast cereal, the finished product in this example. The heavy blue lines above the raw materials, corrugated paper plant, and label plant boxes indicate the areas where purchasing needs to focus to procure the materials needed for cereal manufacturing.

In addition, to the raw materials, the company also purchases paperboard from a paper manufacturer and labels from a label manufacturer. In turn, the paper manufacturer purchases trees to make the paper, and the label manufacturer purchases semi-finished stock to make the labels. After making the cereal and packaging it, the cereal manufacturer sends the cereal to the distributor, which then ships the product to the grocery store at which the end customers purchase their cereal. Throughout this sample supply chain, the purchasing of goods and services takes place between the various entities.

The figure shows how materials and products move from one entity to another while information (e.g., specification, quantities, and desired receiving date) also flows between the various entities. This information flow is important because it is needed to ensure the right products are delivered at the right place, the right time, and the right price.

The Importance of Procurement

-

The raw materials and intermediate goods and services needed in the production of goods and services.

-

Finished goods and services required for resale or for operational purposes.

-

Capital goods and consumables needed for the business.

Product enhancement: Procurement can also improve products and process designs by helping introduce new technologies into companies’ product and service offerings. For example, procurement can work with internal and external engineering personnel and suppliers to improve product reliability and performance while also reducing costs.

-

200,000,000 cases × 12 bottles-/case = 2,400,000,000 bottles

-

2,400,000,000 bottles × ¼ cent savings ($0.0025) per bottle = $6,000,000/year

Reference: Warehousing Operations Certification Track. LINCS in Supply Chain Management Consortium. May 2016. Version: v2.22. www.LINCSeducation.org.