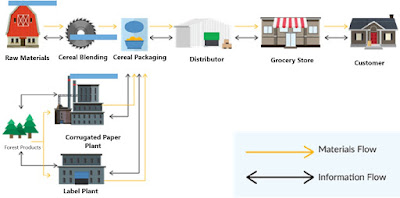

A supply chain is a network of people, processes, resources, and technologies in an organization that works collectively to produce products and services for an end-user, or customer. Supply chains have existed since people began trading goods and services. They have evolved from exchange trading on the Silk Trade road in the 1400s through supplying the troops in World War I and World War II to the complex networks of today’s global supply chains. Supply chains now consist of multi-national, global networks of companies working together to build products and provide services.

What is a Supply Chain?

A supply chain is a network of individual functions within an organization that begins with the development of a strategic plan and ends with the delivery of a product or service. Those functions are listed below;

0. Demand Planning

1. Supply Management and Procurement

2. Inventory Management

3. Warehousing Operations

4. Manufacturing and Service Operations

5. Transportation Operations

6. Customer Service Operations

It is immensely dangerous to business health to manufacturing a product without first planning what inventory will be required and when it will be needed. It is equally risky to attempt to obtain goods and materials from suppliers without a demand plan that feeds procurement purchase requisitions in order of priority based on need dates and supplier lead times. Without linkages in the entire supply chain, chaos would occur and the company would soon have to close its doors. Now it is easier to see that the demand plan drives and signals procurement for the orderly acquisition of goods and materials, which in turn enables an organization to receive and stock inventory in a warehouse, etc.

For example, before a garment can be made available to consumers, it goes through many steps from farmers to retailers. Farmers buy seeds and fertilizers to grow cotton, which are sold as raw material to yarn processors that employ their factories to convert the yarn into fabric, and fabric into a garment. Throughout the conversion process, there are other raw materials needed like dyes, labels, trims & accessories, chemicals etc. The finished products are then combined into larger packages, transported to warehouses, and subsequently distributed to the fashion outlets.

There are often levels of suppliers within a supply chain called tiers. Suppliers that sell directly to factories or main operators are referred to as tier-one suppliers; suppliers that sell to tier-one suppliers are referred to as tier two suppliers. This cycle continues into tier three suppliers, tier four suppliers, etc. The final customers who purchase and consumes products and services are called consumers or end customers. End customers’ needs and wants are the driving force behind the entire supply chain.

Examples of Supply Chains in Use

All companies are part of at least one supply chain, whether they sell directly to the end customers, provide services, manufacture products, or extract raw materials from the earth. For example, a customer may go to a Walmart store to buy a T-shirt. In this case, the supply chain begins by planning to satisfy customer needs through a sales forecast for the T-shirt.

Walmart, as a manufacturer of T-shirts, develops a forecast for sales; from that forecast, a demand plan is developed that enables its procurement department to procure the raw materials used to make the T-shirts along with Packaging, labels, and other necessities. These procured items are received, stored, and then used in the manufacturing process. The individual completed T-shirts are then packaged in boxes for shipment, transported to distribution centres, and ultimately delivered to retailers like Walmart.

Another supply chain example is based on a customer who needs to purchase laptop computers online. The supply chain includes:

- Defining how many laptops might be sold in a given period (like an annual sale forecast)

- Creating the demand plan to procure the necessary components (inventory) from suppliers to assemble the laptops

- Designing the value-added facility where final laptop assembly will occur

- Ensuring a system exists to control and issue the inventory

- Implementing a team of customer service representatives to take orders and interface with end customers, including Internet live chat to answer questions and provide recommendations. Ensuring assembled laptops are adequately packaged for transportation and reliable carriers are used to deliver the final laptop and associated peripheral.

Sometimes reverse logistics might occur, which require that products (in this case, the laptop) returned by the customers travel in the opposite direction through the supply chain. Reverse logistics is a necessary process for product returns resulting from products that are defective, products that require an upgrade or refurbishment, preventive maintenance, or even product recalls stemming from safety or environmental concerns. Typically, customers will interact with the customer service department to determine the nature of a problem, and customer service personnel will issue a return material authorization along with shipping instructions and other details.

Supply Chain Management (SCM)?

SCM is a comprehensive approach to the management of the entire flow of data, information, materials, and services of the individual supply chain function previously mentioned. The ability to link these functions and integrate them with other elements in the business process is dictated by the overall management strategy. Therefore, the management of the supply chain cannot be viewed as an independent, standalone organization and must be arranged to work in concert with other business processes, functions, and departments.

The Council of Supply Chain Management Professionals (CSCMP) is a professional organization that supports the professional development of its worldwide membership. As defined by CSCMP,

“Supply Chain Management encompasses the planning and management of all activities involved in sourcing and procurement, conversion, and all logistics management activities. Importantly, it also includes coordination and collaboration with channel partners, which can be suppliers, intermediaries, third-party service providers, and customers. In essence, supply chain management integrates supply and demand management within and across companies. Supply Chain Management is an integrating function with primary responsibility for linking major business functions and business processes within and across companies into a cohesive and high-performing business model. It includes all of the logistics management activities noted above, as well as manufacturing operations, and it drives coordination of processes and activities with and across marketing, sales, product design, and finance and information technology.” (CSCMP, 2014)

SCM takes into consideration activities involved in confirming that products from the raw material stage are turned into finished products and delivered to customers. These activities include:

- Sourcing of raw material and parts,

- Manufacturing and assembling,

- Warehousing and controlling inventory,

- Entering and managing orders,

- Finishing, customizing, and packaging,

- Distributing across all channels,

- Delivering to final customers,

- Managing relationships with suppliers,

- Managing relationships with customers,

- Maintaining the information systems necessary to monitor the above activities.

SCM thus coordinates and integrates these activities into a continuous process, linking the entities together to ensure supply chains are competitive and satisfy customers with the right products at the right prices.

Fahad Mahmud

Lecturer (Technical), SKTEC

Department of textiles, Ministry of Textiles & Jute

Texpedi.com

Check out these related articles:

Thanks for sharing this informative blog for supply chain management. I ma doing my online mba program in supply chain and this info was very useful to me. keep sharing.

Thanks for sharing this info, I am also planing to do my PGDM (Executive) in Global Logistics & Supply Chain Management from distance from reputed college

Thanks for sharing your article, keep posting

BLOCKCHAIN FOR SUPPLY CHAIN MANAGEMENT & LOGISTIC

Best practice in supply chain management starts with the basics of management. Cargowise support is largely based on the concept of efficiency in operation and eliminating waste and unnecessary expense. When expenses are reduced for a given level of revenue, profits increase. A few common aspects for succeeding in supply chain management are improving delivery times, reducing errors, and better customer service.

Thank you very much for the inspiration. Stay connected.

This comment has been removed by the author.

Wow! This could be one particular of the most useful blogs We have ever arrive across on this subject. Basically Magnificent. I am also a specialist in this topic therefore I can understand your effort CRM Software