To evaluate how something works under certain established methods or test standards. Textile testing is to check its properties under certain conditions in a standard environment prescribed as per Test standards.

What is textile testing? |What are the main steps in textile testing?

- Checking raw materials

- Monitoring production

- Assessing the final product

- Investigation of faulty material

- Product development and research

List of Some Common Fabric Tests?

- Dimensional Characteristics- A) Length, B) Width, C) Thickness

- Threads/Inch – EPI, PPI, CPI, WPI

- Count- Warp & Weft

- Weight,

- Crimp%,

- Strength,

- Abrasion & Pilling,

- Handle a) Stiffness, b) Drape, c) Crease Resistance & crease recovery,

- Flame Retardancy,

- Water repellence.

What is fabric crease?

This is a fabric defect evidenced by a break line or mark in a fabric generally caused by a sharp fold. Crease appears when the fabric is distorted in such a manner that part of it is stretched beyond its elastic recovery. During creasing the upper surface of fabric goes on extension and lower surface goes on compression.

What is crease resistance?

Crease is a fold in a fabric introduced on intentionally at some stage of processing and the resistance to creasing of textile material during use is known as crease resistance. The crease resistance of wool fibre is very good but for the cellulose material it is not good. Amongst the textile materials the order of diminishing crease resistance is wool, silk, acetate rayon, viscose, rayon, cuprammonium rayon, cotton, flax etc.

What is crease recovery?

It is the property of a textile material by which it can return to its former shape after being creased. The measure of crease resistance is specified quantitatively in terms of crease recovery angle. The crease recovery of a fabric can be increased by resin treatment.

What is resin treatment?

The addition of thermosetting resins applied in the finishing process, used to control the shrinkage of a fabric and add durable press characteristics.

👉Examples of resin applied in finishing process:

i. Urea formaldehyde- UF

ii. Dimethylol dihydroxy ethylene urea-DMDHEU

Advantages of resin treatment?

- Improve the resistance to and recovery from creasing.

- Smooth drying properties after laundering.

- Durable effects may be imparted by intermediate mechanical treatment.

- Reduce laundry shrinkage.

- Increase dry tensile strength and greatly increased wet tensile strength of rayon.

- Improved fastness to washing and rubbing of most dyes.

- Decrease water imbibition and more rapid drying.

- Improved handle and drape of fabrics.

- Increase weight.

- Increase resistance to distortion of fabrics with improved retention of garment shape and freshness.

- Improved resistance to slippage and fraying.

- Vehicle for modern flame- proofing.

- Increased resistance to photo-degradation and weathering

- Increased resistance

to rotting.

Disadvantage of resin treatments?

- Lower abrasion resistance for misapplication of the finish.

- Lower tearing strength for misapplication.

- Unpleasant odours under certain condition.

Method of measuring crease recovery?

- The Shirley crease recovery test.

- Continental method.

- The LIBRA sunray crease evaluator.

Shirley Crease recovery tester?

👉Construction:

- The instrument consists of a circular dial, which carries the clamp for holding the specimen.

- Directly under the centre of the dial is a knife-edge and an index line for measuring the recovery angle.

- The scale of the instrument is engraved on the dial.

Working Procedure:

- A specimen is cut from the fabrics with a template 2 inch long by 1 inch wide.

- It is carefully creased by folding in half placing it between two glasses and adding a 2 kg weight.

- After 1 min, the weight is removed and the specimen transferred to the fabrics clamp on the instrument and allowed to recover from crease.

- As it recovers, the dial of the instrument is rotated to keep the free edge of the specimen in line with the knife-edge.

- At the end of the time period allowed for recovery, usually 1 min the recovery angle in degrees is read on the engraved scale.

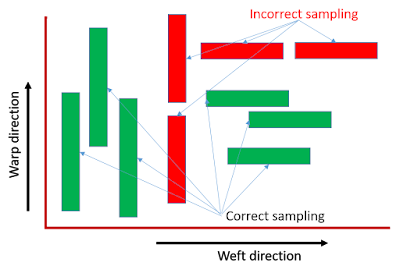

- Warp and weft way recovery are reported separately to the nearest degree from the mean values of ten tests in each direction.

- The load, time of creasing and recovery time may be altered to suit particular cases.

- The specimen should be conditioned and tested in a standard testing atmosphere.

- Random sample should be taken. Selvedge, piece ends, creased or folded regions should be avoided.

Difference between crease resistance and crease recovery?

Crease resistance |

Crease recovery |

Crease resistance is such a property of fabric that resists fabric from creasing. | Crease recovery is a fabric property that indicates the ability of fabric to go back to its original position after creasing. |

Crease resistance is generally measured by bending elasticity. | Crease recovery is the measure of crease resistance specified quantitatively in terms of crease recovery angle. |

Crease resistance comes into play before the fabric is creased. | Crease recovery comes into play after the fabric has been creased. |

Crease resistance resists the stretching and compression of molecular chain of fibre polymer. | By crease recovery property the stretched or compressed polymer chain comes back to normal position. |

Texpedi.com

Check out these related articles:

All of your article is very informative . I think this is the best Textile blog around the web. Keep posting like this more