Crease Resistance

Introduction

The crease is a fabric defect evidenced by a break line or mark or folds in a fabric generally caused by a sharp fold. Crease appears when the fabric is distorted in such a manner that part of it is stretched beyond its elastic recovery. During creasing the upper surface of fabric goes on extension and lower surface goes on compression. The resistance to creasing of textile material during use is known as crease resistance. Amongst the textile materials, the decreasing order of crease resistance is wool, silk, acetate rayon, viscose, rayon, cuprammonium rayon, cotton, flax etc.

Crease recovery

It is the property of a textile material by which it can return to its former shape after being creased. The measure of crease resistance is specified quantitatively in terms of crease recovery angle. The crease recovery of fabric can be increased by resin treatment.

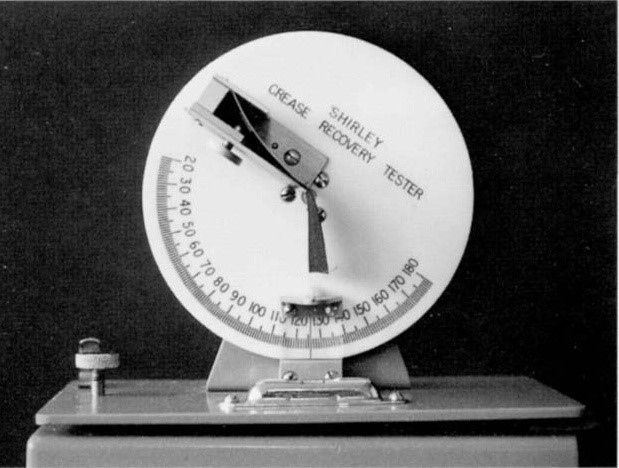

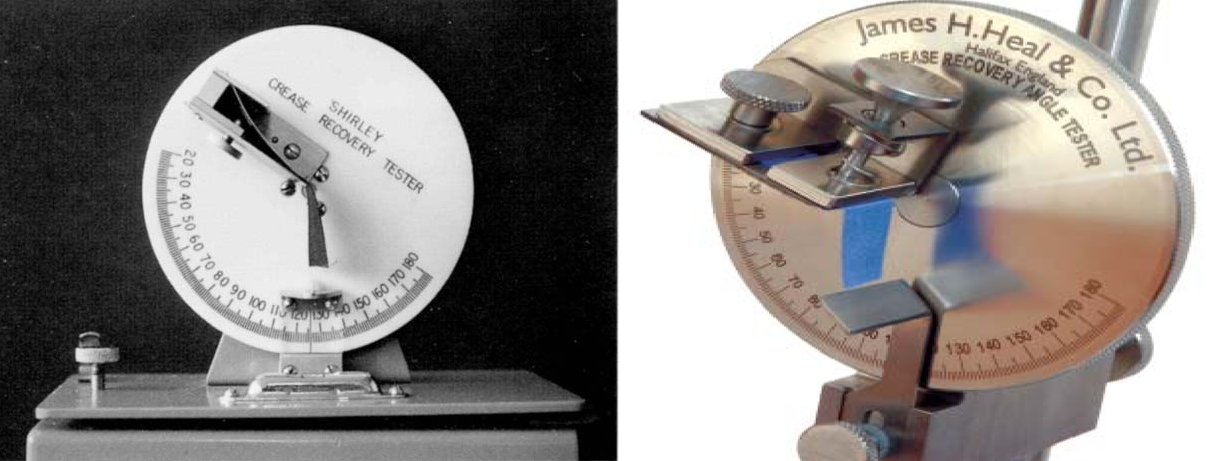

Shirley Crease recovery tester

👉Description of Shirley Crease recovery tester:

- The instrument consists of a circular dial which carries the clamp for holding the specimen.

- Directly under the centre of the dial is a knife edge and an index line for measuring the recovery angle.

- The scale of the instrument is engraved on the dial.

👉Working Procedure of Shirley Crease recovery tester:

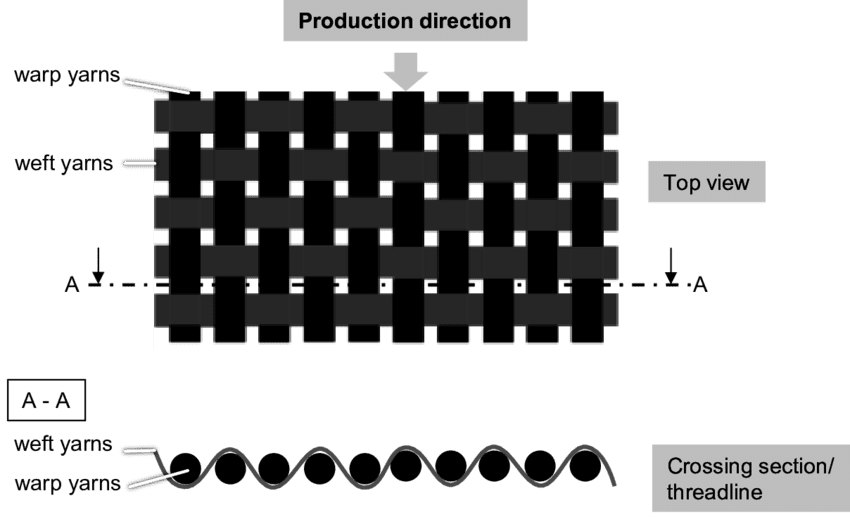

- A specimen is cut from the fabrics with a template 2 inch long by 1 inch wide.

- It is carefully creased by folding in half placing it between two glass plates and adding a 2 kg weight.

- After 1 min the weight is removed and the specimen transferred to the fabrics clamp on the instrument and allowed to recover from the crease.

- As it recovers, the dial of the instrument is rotated to keep the free edge of the specimen in line with the knife edge.

- At the end of the time period allowed for recovery, usually 1 min the recovery angle in degrees is read on the engraved scale.

- Warp and weft way recovery is reported separately to the nearest degree from the mean values of ten tests in each direction.

👉Factors to be considered while testing the Crease recovery:

- The specimen should be conditioned and tested in a standard testing atmosphere.

- The random sample should be taken.

- Selvedge, the piece ends, creased or folded regions should be avoided.

👉Difference between crease resistance and crease recovery:

Crease resistance | Crease recovery |

Crease resistance is such a property of fabric that resists fabric from creasing. | Crease recovery is a fabric property that indicates the ability of a fabric to go back to its original position after creasing. |

Crease resistance is generally measured by bending elasticity. | Crease recovery is the measure of crease resistance specified quantitatively in terms of crease recovery angle. |

Crease resistance comes into play before the fabric is creased. | Crease recovery comes into play after the fabric has been creased. |

Crease resistance resists the stretching and compression of the molecular chain of fibre polymer. | By crease recovery property the stretched or compressed polymer chain comes back to normal position. |

Texpedi.com

Check out these related articles: