What are the operations involved in Blow room?

Blow Room:

👉Blow Room consists of a number of machines used in succession to open and clean the cotton fibre to the required degree. 40 to 70% trash is removed in this section. Opening, Cleaning, Mixing, Blending, Lap forming are the main functions in blow room.

Carding:

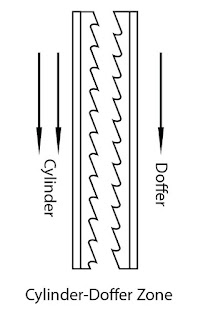

👉Carding may be defined as the reduction of an entangled mass of fibres to a filmy web by working between two closely spaced, relatively moving surface clothed with sharp wire points. Cleaning, Fibre individualizing, Disentangling of neps, Sliver forming are the main functions in carding process.

Draw Frame:

👉Parallelizing the fibres, increasing evenness (decreasing CV%), removing fibre hooks.

Lap Former:

👉Lap forming

Comber:

👉Short fibre removal, fibre hooks removal, making fibres more parallel.

Simplex:

👉Drafting(attenuation of sliver), twisting and winding the roving on to a suitable package which can be used as input package of ring frame.

Ring Frame:

👉Drafting, Twisting yarn forming and winding the yarn on to a suitable package.

👉Winding Machine:

Yarn faults removal ( thick, thin, neps, foreign fibre etc.), winding the yarn on to a suitable package which can be sold.

What are the main properties of textile fibre ?

1.Fibre fineness: It is one of the important properties of fibre. It influences-

- Spinning limit

- Yarn strength

- Yarn evenness

- Yarn fullness

- Drape of the fabric

- Lustre

- Handle

- Productivity of the process

Micronnaire value (MIC), tex, dtexare used to specify fibre fineness. Cotton fineness ranges from 3.1 MIC to 6 MIC.

2. Fibre length: Fibre length is also one of the the most important characteristics. It influences-

- Spinning limit

- Yarn strength

- Yarn evenness

- Handle of the product

- Lustre of the product

- Yarn hairiness

- Productivity

Cotton fiber length is specifies by mm or inch. Length of cotton fibre ranges from 0.5 inch to 2.5 inch.

3. Strength: Strength is the dominating characteristic of fibre. The minimum strength of textile fibre is approximately 6 cN/tex. Yarn strength depends on fibre strength. Some significant breaking strengths of fibres are:

- Polyester: 35-60 cN/tex

- Cotton: 15-40cN/tex

- Wool: 12-18cN/tex

4. Fiber elongation: Elongation is specified as a percentage of the starting length. Elastic elongation is very important for textile material. Fibre elongation should therefore at least 1-2%(glass fibre) and preferably slight more. Elongation of cotton is 6-10% and wool is 25-45%. Crease resistance is dependant on fibre elongation properties.

5. Fiber Maturity: The maturity of cotton depends on the secondary cell wall thickness. Unripe fibres shows less maturity. Immature and dead fibres create following problems:

- Loss of yarn strength

- Neppiness

- A high proportion of short fibre

- Varying dyeability

- Processing difficulties

Contamination in raw cotton

In addition to usable fibres, cotton stocks contains foreign matter of various kinds:

1.Vegetable matter

- Husk portion

- Seed fragments

- Stem fragments

- Leaf fragments

- Wood fragments

2. Mineral material

- Earth

- Sand

- Ore dust

- Coal dust

3. Other foreign matters

- Metal fragments

- Cloth fragments

- Packing material

Texpedi.com

Check out these related articles:

Yarn manufacturer

Here is some knowledge and the video about yarn factory.