Woven roving fabric | Nowadays, woven Roving is one of the most valuable materials because of its wrapping direction. Moreover, another powerful strength is the 90-degree orientation to each other. There is a massive amount of use in the shipping industry, military industry, aircraft industry, chemical industry, mica tape, fiberglass tape, and sports goods if we see the composite construction. This article will explain the full details of the woven roving fabric.

👉What is woven roving fabric?

The fabric material is woven in a particular pattern to give high strength when used to build up a covering, or another composite framework is known as woven roving fabric. Or on the other hand, we can say that Woven Roving is a bidirectional texture made by joining direct wandering in a plain weave design. As the intertwining between the different glass filaments is consolidated during its creation, the fabric becomes heavier. These fabrics are viable with a broad scope of the resin system.

What is woven roving fabric made of?

Woven roving is a form of fabric material made out of glass fibers weaved in a specified pattern. Technical textile factory produced woven roving fabrics using continuous glass fiber roving’s, which are interwoven into significant burden fabrics. Most of the time, the company used to expand the flexural and effect strength of laminates. In the general role of woven Roving, the estimated ratio of resin/reinforcement is 1:1 by weight. Thus, woven Roving is accessible in an assortment of weights, weaves, widths, and completions to suit a broad scope of utilizations.

👉Properties of fiberglass woven roving fabrics:

Table 1. Properties of fiberglass woven roving fabric.

| 01 | Fabric name | Woven roving fabric |

| 02 | Materials | Fiberglass |

| 03 | Weave type | Satin or Twill |

| 04 | Insulation | Excellent |

| 05 | Heat resistance | Good |

| 06 | Tensile strength | Excellent |

| 07 | Corrosion resistance | Good |

| 08 | Fiber content | Higher |

| 09 | Compatible with | Hand lay applications |

👉How is woven roving fabric made?

You will require a few elements to make this fabric. The two primary components are (i) resin and (ii) fiber reinforcement.

- First is a liquid resin that hardens to a rigid but brittle solid.

- The second is the fiber reinforcement. That is placed in the liquid resin before it hardens. This reinforcement gives the cured resin. Its tremendous strength Trap plastics has a wide selection of fabric reinforcements.

👉Type of fabric reinforcements for making woven roving fabric:

There are different types of fabric reinforcement. So, how to select the one that is right for you. Fiber reinforcement comes in several primary forms.

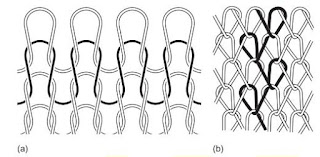

Cloth: First is the cloth which comes in widths ranging from one inch to fifty inches. The cloth accurately described its woven appearance.

Mat: People identify it by strands going every which way. One of the unique characteristics of a mat is Its ability to conform to compound curves and complex shapes.

These fibre and fabric are held together with glue that dissolves in polyester resin. When that happens, the fibers behave like papier Mache and conform to shapes that most cloth could not do.

Roving: Roving has large bundles of strands in a very coarse weave and knighted.

Knytex: This is a combination of short strand mat and long strand roving when selecting a fiber reinforcement.

👉Factors to be considered to produce woven roving fabrics:

There are four characteristics to consider: all of these are critical.

- Weight

- Strand direction

- Weave and fiber

- Fiber composition.

Let’s look at these four in detail-

Weight: the amount of reinforcement in the fiberglass product determines its strength. Reinforcement is proportional to strength. Technicians measure by their weight in ounces per square yard. The scales generally say the heavier the fabric, the greater the strength.

The challenge is to select fabric strong enough for the intended purpose but not heavier than is needed. Most products made with fiberglass consist of many layers of fabric tap plastic. It carries fabrics as light as 3.7 ounces per square yard up to these 24 points. So, 9-ounce material is the second factor in choosing a reinforcement.

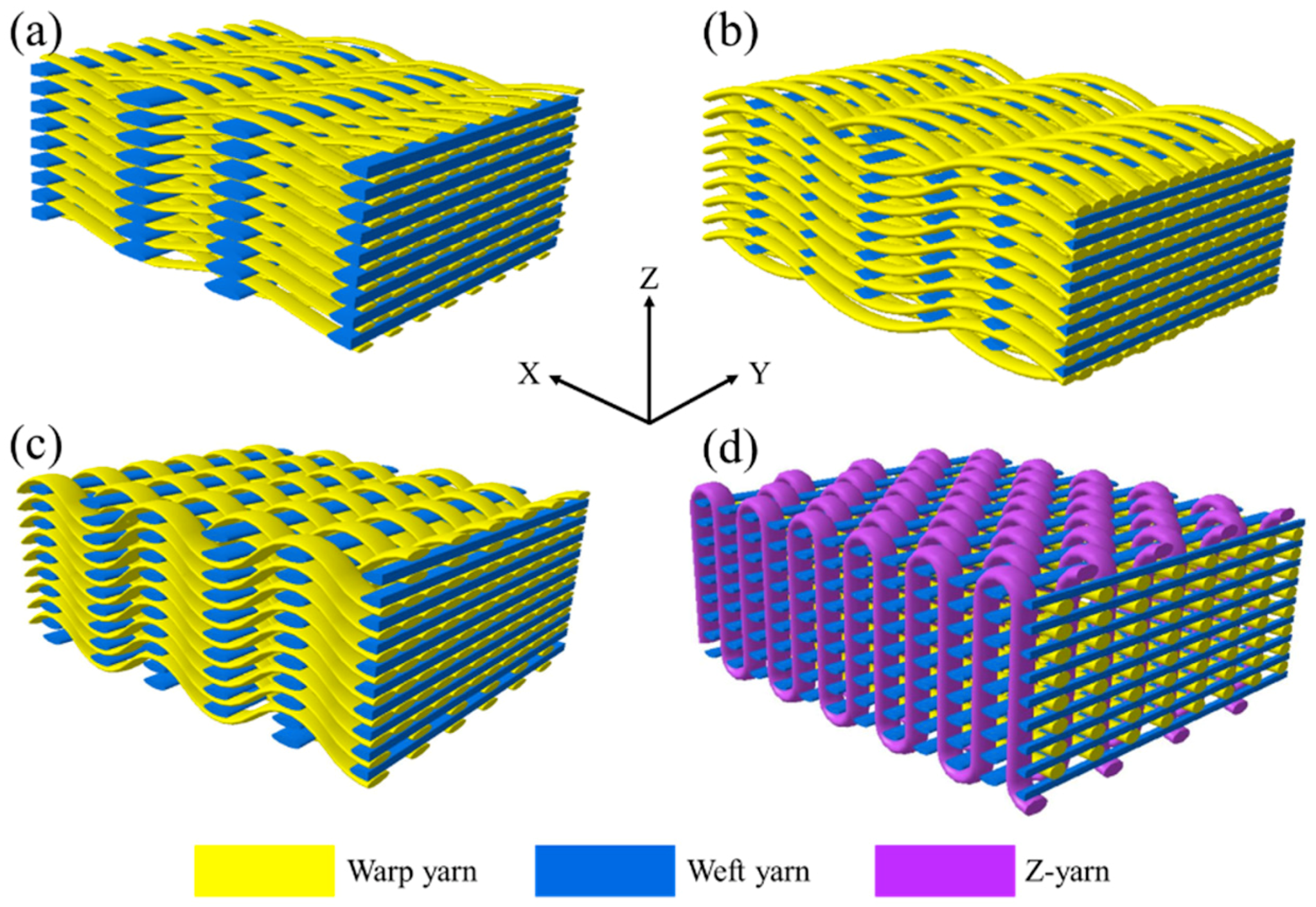

Strand Direction: There are two types of fabric direction of the strand of fiber: unidirectional fabrics and bi-directional Strands fabrics.

👉Why does the fabric direction matter?

We have laid up the unidirectional fabric with resin. When we run the strands this way, it is powerful. However, if we turn the piece 90 degrees this way, it is weakened substantially because of the direction of the fibers.

Now, if we see bidirectional fabrics, their fibers are going 0 and 90 degrees. It is vital in both directions because it has a fabric called a mat. Its fibers go in every direction. It provides equal strength in all directions. Therefore, it is omnidirectional and almost always used in conjunction with a cloth for maximum strength.

Weave and fiber: The third feature of the fabric is waves. Its waves by that, we mean the pattern. The rule is to wove the threats in here with two pieces of 9-ounce cloth. They are the same weight, same materials, same fiber direction, but they are different here. That is called plain weave.

Fiber composition: The fourth characteristic of the fabrics is fiber composition.

E- glass:

It is also the most economic fiberglass fabric made out of microscopic strands of glass. There are hundreds of strands in every thread.

S-glass:

The second fabric material is s-glass. It is also a glass that has been chemically modified to be much stronger.

Carbon fibres:

The third kind of fiber is carbon or graphite. You can easily recognize its black appearance; carbon fiber offers extreme rigidity with minimal weight because of its lightweight. Military and commercial aircraft, competition sailboats use it.

Aramid:

The fourth kind of fabric is aramid. It is a familiar brand which is also known as Kevlar. It has extreme impact resistance and is appropriate for locations that need to withstand such forces by selecting the proper weight, fiber direction, weave, and fabric composition. You can produce the best performance with the least weight. Tap plastics have the materials you need.

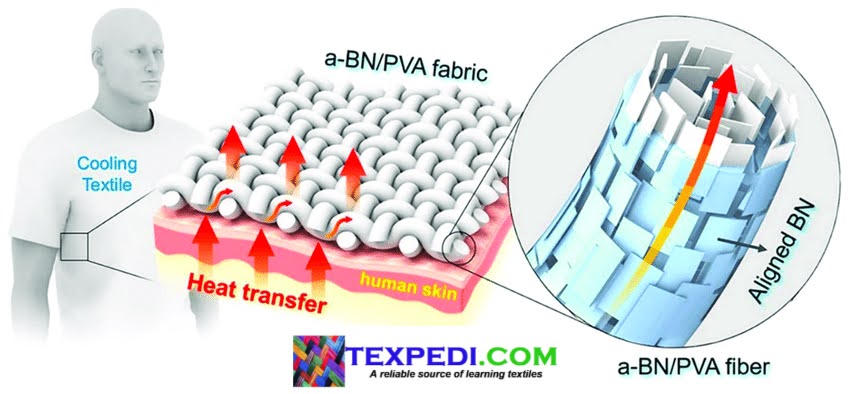

👉Characteristics of woven roving fabric:

1.High force and speedy wet out

2. Suitable designable characters are available.

3. Electric protection & anti-corrosion quality.

4. Provides drape-ability, quick wet-out, and fair coverage.

5. Regularly offered in a plain weave, different weaves accessible upon demand.

👉Applications of woven roving fabrics:

Woven Roving Fabrics are most suitable for hand lay applications where thickness and strength are required. Woven Roving is an incredible choice in boat building, mainly when utilized with chopped strand mats. Woven Roving is a coarse plain hefty weave fabric.

Its bundles are woven together freely at 90 degrees. Woven Roving is useful for rapidly developing thickness. A disadvantage is that with the woven packs, there is creasing. The crease focuses can break.

The cause is bumpiness (unevenness) of the woven. It isn’t easy to follow another layer of Roving or material to it. There will be many voids abandoned whenever done as such. It will likewise be truly substantial from the additional resin expected to make up for those voids. It tends to be substantial, however.

👉Conclusion:

Woven Roving is valuable because of its use in a multitude of ways. From truck bodies to boats, aircraft canoes, surfboards, tanks, and wind turbines use fiberglass woven roving fabric for the construction. By the way, you should never fold fabric. Folding can damage the fabric. Instead, it would help if you rolled onto a tube to avoid wrinkles. The builder must decide how much reinforcement is necessary and then pick the appropriate fabric.

Author courtesy:

Md Mahedi Hasan

B.Sc. in Textile Engineering (Apparel Engineering)

Textile Engineering College, Noakhali, Bangladesh

You may also like:

Texpedi.com

Check out these related articles:

The article is incredibly helpful and offers some of the most useful information. woven roving fabric