Md. Emdad Sarker

Assistant Professor

Department of Fabric Engineering, BUTEX

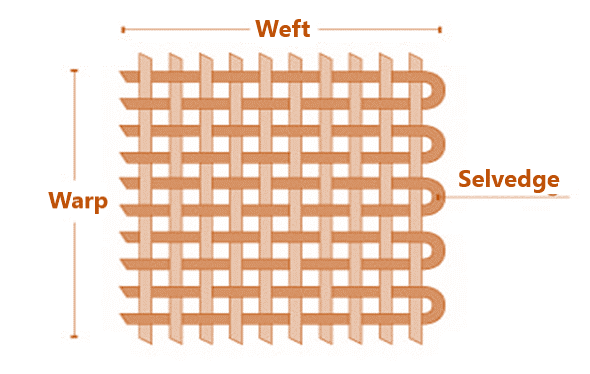

Knitting is another method of fabric production, where yarns are interlooped to form a flat fabric. Two types of knitting exist, namely, warp knitting and weft knitting.

Assistant Professor

Department of Fabric Engineering, BUTEX

Knitting is another method of fabric production, where yarns are interlooped to form a flat fabric. Two types of knitting exist, namely, warp knitting and weft knitting.

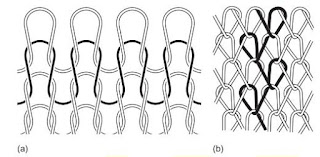

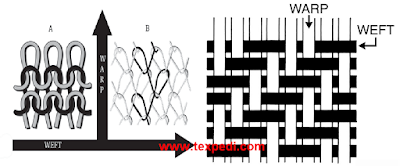

Weft knitting is the most common method in use, after weaving, because of its versatility and Weft-knitting technology also offers considerable advantages in terms of cost, flexibility, and versatility as compared to weaving technique in the production of suitable structures for a contourable protective material. This, however, has not been proven successful, mostly because of the low initial modulus of a knitted fabric, which is due to the high degree of interlocking of the yarns. Since the fabric is formed by interlocking of the yarns, the yarns are flexible and are free to move within and out of the loops, and thus stretch when a load is applied, resulting in low initial modulus, low capital and low floor costs. A weft-knitted fabric can be produced using one single strand of yarn Figure-1(a). while a warp-knitted fabric or a woven fabric requires the same number of yarns as required through the width of the fabric Figure-1(b).

|

| Figure-1: Representation of knitted structure (a) weft-knitted structure; (b) warp-knitted structure [1] |

Technical knitting is an advanced capability which allows textile components to be used in the technical field rather than traditional textiles. Technical knitting is an exciting capability, making it possible to create ground-breaking textile structures, constructions and textures as fully fashioned textile components which just can’t be achieved in flat-weaving [2].

Manufacturer of Technical Knitted Fabrics

TEC-KNIT, a manufacturer of technical textiles are producing the following technical knitted fabric [3].

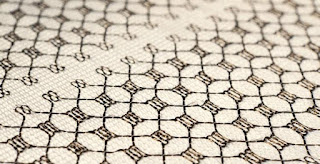

Glass Knit

This is a unidirectional non-crimp fabric of glass rovings with a grammage of 80 to 2500 grams per square metre. The advantages include drapability, the setting threads adaptable to PES, glass and metal, and the built-in functions such as heating or sensing. Glass-KNIT is applied, for example, in the fields of wind power, automotive, sports and construction as shown in Figure-2.

|

| Figure-2 Glass Knit |

Carbo Knit

This unidirectional non-crimp fabric made of carbon rovings with the fineness of 12 to 50K with a grammage of 200 to 2000 grams per square metre impresses with its setting thread out of PES, glass and or metal. Functions such as heating or sensing can be integrated into the drapable fabric. It is used in lightweight construction with complex shapes and impresses with its low-waste processing as shown in Figure-3.

Heating Fabrics

The pure metal heaters cover a wide range of temperatures. The use of tungsten alloys also enables high-temperature applications. Examples of applications include a steering wheel or seat heaters, mould heaters in lightweight construction, or interior heaters in cars and aircraft as shown in Figure-4.

Protective Fabrics

Fabric grids fulfil a wide range of functions when areas are to be separated from one another, for example, for aesthetic, organisational or protective reasons. The fabric meshes are used as shown in Figure-5, for example, as safety nets, or for passenger safety in vehicles.

|

| Figure-5 Protective Fabric |

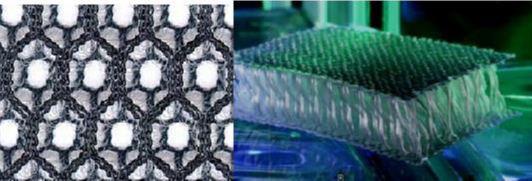

Insulation Fabrics

For our thermal insulations, we use glass and metal spacers as shown in Figure-6 that protect the interior against heat and cold or ensure a uniform temperature. This knitted fabric is used, for example, in the manufacture of hoses or Nomex articles in the field of occupational safety.

|

| Figure-6 Insulation Fabric |

Some other technical knitted fabrics manufactured by TEC-KNIT:

- Energy-absorbing knit

- Cut protection

- Heavy copper mat

- Heating on elastic base

- Elastic glass

- Fabric airbag hinge

- Textile reinforcement

- Protection against vandalism

Conclusion

Nowadays, fabrics are knitted not only for traditional wear but also for high performance in technical application. So major changes take place in the manufacturing of knitted fabric in terms of fiber selection, machine types and finishing process to achieve the desired end-use properties. These substances are not only used for a definite purpose but also for longevity, strength and lightweight. Day by day the application of technical knitted fabric is being increased with a remarkable rate of uses.

References:

- A. R. Horrocks and S. C. Anand, Handbook of

Technical Textiles Volume-2. 2000. - https://www.camirafabrics.com/technical-knitting

- https://www.tec-knit.de/en

You may also like:

Texpedi.com

Check out these related articles:

It is our pleasure to share your enormous knowledge with textile engineering students. Hope they will enjoy reading.

Thanks Texpedia for publishing the article