Introduction

Fabric inspection, to ensure the defects free quality fabric, is one of the most important process in the quality control and assurance department. Fabric inspection is usually done during producing fabrics via different fabric manufacturing techniques such as knitting, weaving, etc. and this inspection is called online quality inspection. In addition, fabrics are thoroughly inspected before dispatching to next subsequent process (i.e., sewing section). Sewing section also checks the fabrics received from fabric producing units before cutting for garments. What is Fabric Inspection?

Fabric inspection is a systematic approach executed to detect or identify any kind of defects in fabrics that are undesired in the finished garments. So, it is a quality check that intends to reduce the fabric flaws as much as possible to meet the customers’ requirements.

Necessity of Fabric Inspection

Fabric inspection is very essential process especially under the quality control and assurance department. It is done to detect various types of fabric faults before being cut for garments making. The more fabric faults that can be identified before making garments, the better. This ultimately improves the quality of the garments and reduces the making cost as well.

For example: one roll of fabrics has not been inspected well as per the customers’ requirement and forwarded to the sewing section. Sewing section, as usually inspects maximum 10% of the fabrics, proceed to cut the fabrics for making the garments. The garments after being made with faulty fabrics are rejected after the quality check (either at the online QC or at the final garment inspection). If the faults detected are not major, they are sent back to the respective process and tried to alter. However, quality certainly deteriorates while altering the faults. Anyway, if the faults are major, then the garments are rejected. So, all the process after fabric manufacturing to garments making are in vain and incur nothing else but the financial losses. Therefore, when there is a fault made in any process, the quality of the end-product can be ensured by identifying and correcting it immediately.

Different types of fabric inspection techniques

Manual inspection

This is the most widely used technique in the textile and clothing industry. ASTM D5430-93 (Standard Test Methods for Visually Inspecting and Grading Fabrics) is followed to visually detect the fabric faults. Fabrics from roll are passed through a light chamber, faults are detected manually. The faults are identified based on their sizes and noted in a prescribed form. Fabric faults are identified following different techniques. Faults are scored based on their sizes. However, this scoring is different for different system. On receipt of fabrics in the warehouse, at least 10% are inspection as per “4 Points” system/10 Points system/2.5 Point system/6.0 Point system. The most used 4 Points system as per below- Sl. No.

| Size of defects | Penalty Points |

01

| 3 Inches or less | 1 Point |

| 02 | Over 3, under 6 Inches | 2 Points |

| 03 | Over 6, under 9 Inches | 3 Points |

| 04 | Over 9 Inches | 4 Points |

A maximum of 4 points are changed in one linear yard. According to the size, quality, and seriousness of the flaw, the 4-Points system allocates 1, 2, 3, or 4 scores (penalty points). A single fault is given no more than 4 penalty points. The system stays the same whether a fault is measured in the length or width direction. Only serious mistakes are considered in this system. There is no penalty score for minor faults. When faults are detected during fabric inspection using the 4-point method, the defect must be given a point value based on the severity or length of the problem. Fabric quality is measured in unit points per 100 square yards in a four-point system.

Points/ 100 Sq. Yd =

Total Points in fabric roll x 36 x 100

Fabric Length in Yards x Fabric width in inches

In general, acceptable level of ‘points per 100 linear yards’ or ‘points per 100 square yards’ are different for different fabric types. For example: For Cotton Twill/Denim: 28 points per 100 square yards (23points per 100 square meters) for individual fabric roll. For All synthetic fabrics: 20 points per 100 square yards (16 points per 100 square meters) for individual fabric roll.

It is usually allowed to have up to 40 points per 100 square yards. Fashion buyers also establish their own requirements for acceptable points, even though ASTM has a standard threshold. Rather of just passing or failing a fabric roll or lot, many factories grade their fabrics as A, B, or C grades.

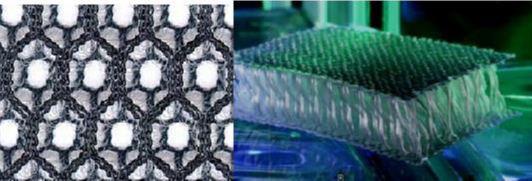

Automatic inspection

There is another technique followed to detect the fabric faults though this is not widely used in the industry. High-speed digital camera is used to identify the faults (if any) in the fabric passing through the pairs of rotating rollers. The faults (size, severity, types) are already embedded with the computerized programs. Whenever, any faults are detected they are automatically noted in the computerized format.

Others

There are some other systems which are very rarely applied for fabric inspection. For example: Dallas system and artificial intelligence (AI) system.

Concluding remarks

Since the fabric cost is almost 70% of the total cost of garments, fabric inspection is very important. It is necessary both for the cost reduction as well as the quality enhancement. If the faults can be identified at the fabric inspection stage, then the potential cost due to the next processes like spreading, cutting, sewing, inspecting will not incurred and thereby reduce the ultimate COM (cost of making) of garments.

Texpedi.com

Check out these related articles: