There are mainly three (3) types of beaters used in blow room and they are explained below-

1. Porcupine,

2. Bladed beater: Beater arms (Multiple bladed beaters),

3. Kirschner beater

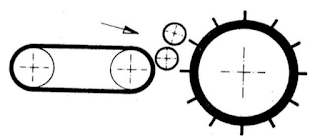

1. Porcupine:

The strikers are arranged at different angles to cover the total width of the m/c in one revolution of the beater. Good opening beater and suitable for long-staple cotton. It separates the fibres by the striker. Simultaneously cleaning is also done.

|

| Porcupine Beater |

2. Bladed beater: Beater arms (Multiple bladed beaters):

The beater bars arranged parallel to the supporting shaft and held by four or five cast-iron arms. Opening and cleaning effect of this type of beater is small. It is hardly found a row, it is only in the form of the double beater scutcher.

|

| Multiple Bladed Beater |

Types of Multiple bladed beaters?

There are two types of Multiple bladed beaters as below-

- Two bladed beaters.

- Three bladed beaters.

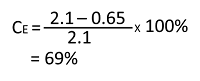

Two bladed beaters:

– Two blades are arranged in both sides and equal distance of shaft.

– Revolution per minute 800-850.

– To clean broken seeds or heavy impurities of fibres.

|

| Two bladed beater |

Three bladed beaters:

– Similar to a two-bladed beater

– Three blades arranged in an equal distance of shaft

– Clean darts like two-bladed beater but are more effective RPM of three blades beater 850-940.

|

| Three Bladed beater |

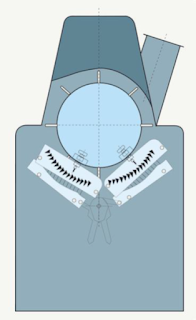

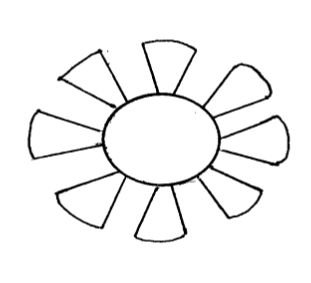

3. Kirschner beater:

In this type of beater, instead of beater bars, pinned bars (pinned lags) are secured to the ends of the cast-iron arms. The relatively high degree of penetration results in a good opening. Kirschner beaters were therefore often used at the last opening position in the blow room line. Modern Kirschner openers are often designed as closed rollers rather than three-armed beater units. The design is simpler and the flow conditions are more favourable.

|

| Beaters with pinned bars |

|

| Rollers with pinned bars |

Texpedi.com

Check out these related articles: