|

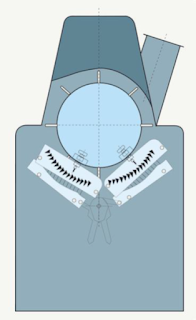

| Two-part Grid |

The influence of the grid on cleaning efficiency?

The grid has a major influence on the cleaning effect via:

• the section of the bars;

• the grasping effect of the edges of the polygonal bars;

• the setting angle of the bars relative to the opening elements;

• the width of the gaps between the bars;

• the overall surface area of the grid.

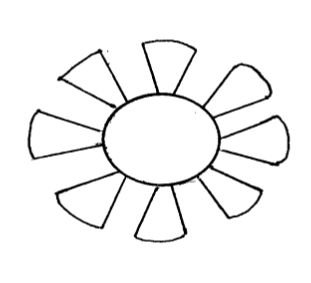

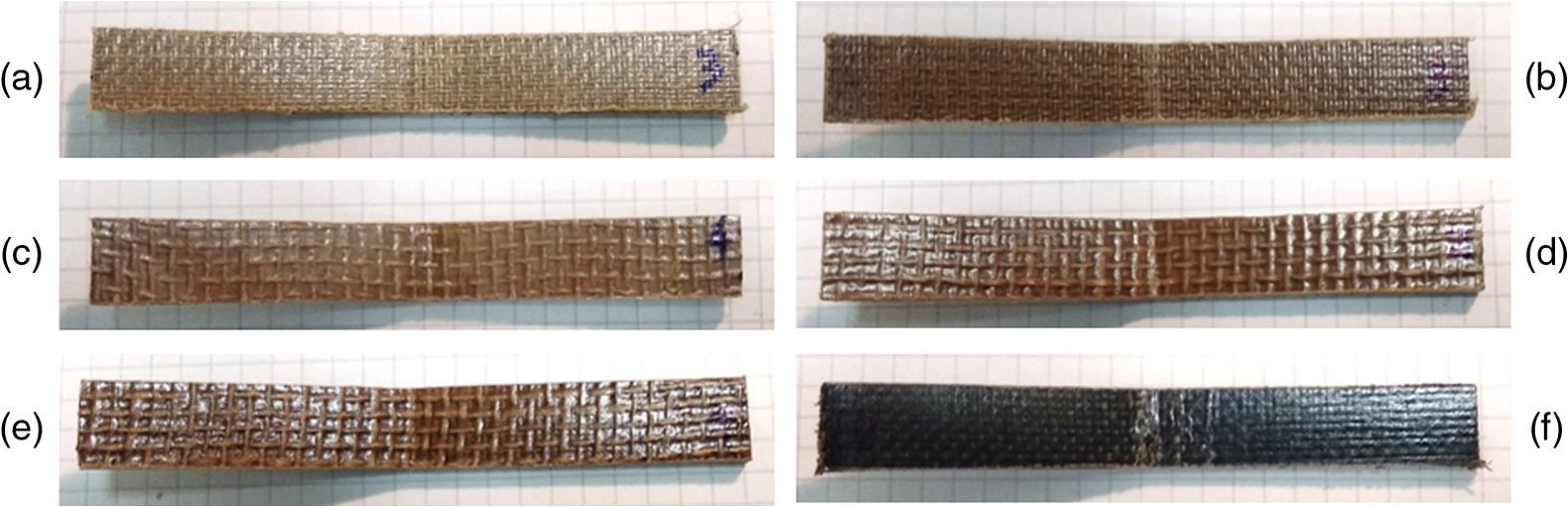

The following elements can be used in the grid:

• slotted sheets (a): poor cleaning;

• perforated sheets (b): poor cleaning;

• triangular section bars (c): the most widely used grid bars;

• angle bars (d): somewhat weak;

• blades (e): strong and effective.

What are the Grid adjustments?

Three basic adjustments:

• Distance of the complete grid from the beater;

• Width of the gaps between the bars (a=closed, b=open);

• Setting angle relative to the beater envelope.

What are the general factors influencing opening and cleaning performance?

Degree of opening, degree of cleaning and fibre loss are influenced by-

– Type of opening roller

– Speed of the opening roller

– Degree of penetration

– Type of feed

– The spacing of the feed from the opening device

– Type of grid

– Area of the grid surface

– Grid settings

– Airflow throw the grid

– Condition of pre-opening

– The thickness of the feed web

– Material throughput

– Position of the machine in the machine sequence.

Check out these related articles: