Emdadul Haq

Lecturer, Department of Textile Engineering, Primeasia University; Bangladesh

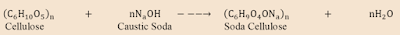

Viscose Rayon is a man-made, natural polymer cellulosic or regenerated cellulose filament or staple fibre. It is manufactured from spruce wood and cotton linters.

Properties of Viscose Rayon Fibre

1. Tenacity and Elongation

As the polymer system of viscose fibre is very amorphous, its filaments or staple fibre are weaker than cotton and result in fair tenacity.

Tenacity : About 2.6 grams per denier

Dry Tenacity : About 1.3-1.7 grams per denier

Wet Tenacity : About 1.4 grams per denier

Elongation at break (Dry) : About 15%

Elongation at break (Wet) : About 25%

| Viscose Rayon Fibre |

2. Moisture Content

Under standard conditions (65% Relative Humidity and 70℉)

Moisture Content : 12-13%

The lower humidity of the atmosphere the lower moisture content of the yarn and vice versa. For example, at 20% R.H. the moisture content of viscose rayon is about 5% and at 90% R.H., it is about 22%.

3. Creep

The elasticity of viscose rayon is not high. If stretched and then released from the strain it does not return to its original length, although for some time afterwards it continues to shrink towards but not completely to its original length. This phenomenon has been described as “delayed elasticity”, “creep” and “Plasticity”. The effect of this behavior is that if ends of yarn are during weaving exposed to sudden strains they may be permanently stretched and will result in “shiners” and streaky dyeing.

4. Density

The specific gravity of viscose rayon is 1.52, which is high compared with wool and cellulose acetate, both of which have value about 1.32.

5. Electrical properties

When viscose rayon quite dry, it is a good insulator but the moisture that it inevitably picks up considerably reduces its value for electrical uses. Viscose is not so liable to develop static charges in textile working as is cellulose acetate.

6. Resistance to light

On exposure to light, photo cellulose is formed and weakening takes place. The loss in strength is less than that which occurs with real silk but more than in case of cellulose acetate.

7. Resistance to Heat

The ironing properties of viscose rayon are satisfactory, although on lengthy exposure to high temperatures it turns yellow.

8. Chemical properties

Acids attack viscose rayon more quickly than they do cotton. The most important single factor is temperature. Cold solutions of acids and sort times of treatment do not usually cause undue tendering. For example, 2% acetic or formic acid is safe at room temperature and 2% oxalic acid may be used at temperatures up to 60℃ to remove iron strains. At high temperatures, acids carbonise viscose.

9. Thermal properties

Viscose and the other two regenerated cellulose fibres show similar thermal properties to cotton, as they can conduct heat energy, minimizing any destructive heat accumulation. However, the shorter polymers and more amorphous nature of the rayon fibres give them a lower heat resistance and poorer heat conductivity than cotton. Viscose is the most common man-made fibre which is either thermoplastic or hygroscopic in nature, enabling it to absorb water molecules very readily. Thus the polymer system of viscose always tends to contain a considerable number of water molecules, which results in breaking of hydrogen bonds. Broken hydrogen bonds prevent the retention of any heat-set.

10. Biological Resistance

Moulds and mildew discolour and weaken viscose-rayon; the initial attack is often made on the farinaceous size applied to viscose warps. Once the goods have been scoured and dyed and the size thereby removes, the danger of attack is less. Moth larvae will eat viscose rayon mixed with wool, but they cannot digest it and will excrete it unchanged; they do not attack all viscose fabrics.

11. Susceptibility to bleach

Sodium hypochlorite, neutral, is the most satisfactory bleach for viscose rayon. Potassium permanganate followed by a cleaning solution of sodium bisulphite may also be used. Hydrogen peroxide can be used at temperatures not exceeding 55oC. Bleaching of piece-goods is not always, or usually, necessary, especially when the viscose yarn has been already bleached, as much of it has, during manufacture.

12. Action of solvents

Dry cleaning solvents do not attack viscose.

13. Hygroscopic nature

Its amorphous polymer system and its polar polymers makes viscose the most absorbent fibre in common use. The slightly more crystalline polynosic rayon is somewhat less absorbent than viscose.

14. Morphology

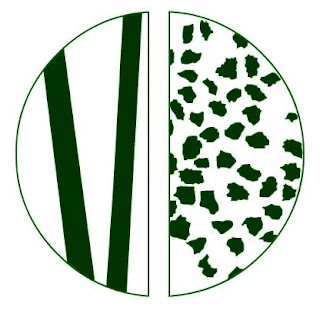

Under the microscope, the longitudinal view of viscose rayon is that of a striated cylinder, whilst the cross-section is highly and characteristically serrated.

Reference:

[1]. MAN-MADE FIBRES- R.W. MONCRIEFF

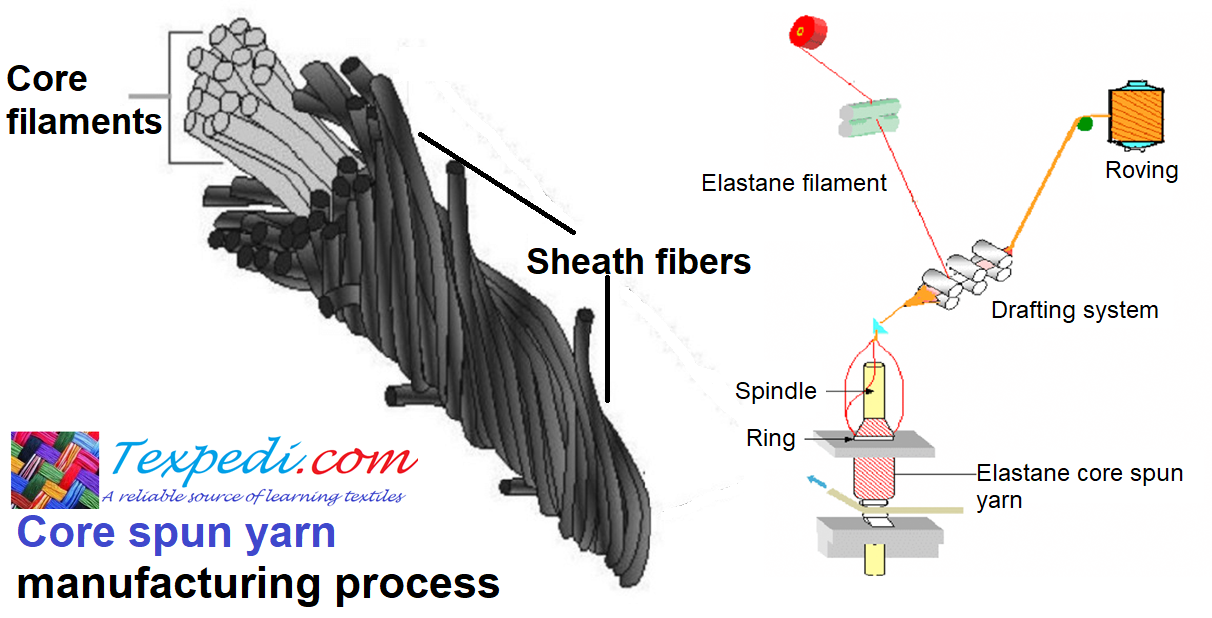

Texpedi.com

Check out these related articles:

2 thoughts on “Properties of Viscose Rayon Fibre”