What is responsive car seat?

What are the common problems of the existing car seat?

- Fixed shape and specific body contour are the main problems of car seats. People are of different types, size, shape and even weight. Everyone does not feel the same comfort with same seats. But it is not possible for the car manufacturers to make the car seat considering individual body shape.

- Sweating at the lower part of the body due to lack of moisture transport mechanism in seat material.

- Poor thermal Conductivity of the seat material.

- When the car seat is lowered down for the weight of the body the surrounding area except the body shape is risen up. Passengers do not feel comfort on this type of seat for a long drive. That is why Car company prefers the contour seat nowadays. But the main and prominent problem of contour shape seat is its fixed shape.

- Sometimes, an extra pillow is being used in the car for extra comfort or support.

|

| Figure 1. Responsive car seat [source: https://doi.org/10.3390/inventions5030030] |

How to solve the existing car seat problems?

| Figure 2. Schematics of responsive car seat |

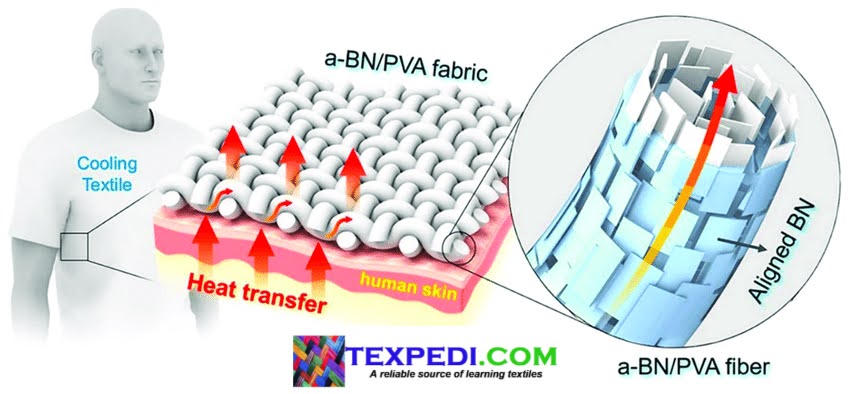

👉2. A pressure is implied on the car seat due to our body weight. In the responsive car seat, some panels with sensor [1-2] can be arranged below the seat. These sensors measure how much pressure has been applied on the seat and change the shape accordingly. That means, the shape of responsive car seat changes according to the human body contact shape. Furthermore, the back support shape changes by the same mechanism. So, if the passenger moves right left or even get off, seat shape changes according to the pressure measurement from the sensors to ensure the maximum comfort.

👉3. There is no need of the extra support in the responsive car seat, while an additional pillow is being used in the existing car seat for getting more comfort. Sensors ensure the required shape for extra comfort with our body movement.

👉4. The sensors used in the responsive car seat, can control the pressure changes caused from the car acceleration and deceleration and neutralize the effects on passengers by changing the shape of car seat accordingly.

👉5. Specially designed microporous 3D spacer fabric can reduce the sweetening of the lower part and back of the body [3-5].

👉6. A smart control panel (such as an android control of car seat) may be effective to accumulate all these features and ensure the comfort properties of the responsive car seat.

Different ways to make your car seat more comfortable

1. A dynamic analysis on sensor arrangement can provide detailed information about how much movement or what type of movement of the car seat may reduce the effects of car acceleration or deceleration. Then this artificial intelligence may be incorporated into the seat. The maximum tolerable range of acceleration and deceleration can be found from car meter reading. Whenever car exceeds this range, then motion will be activated by the sensors. These types of facilities in a car are much essential for us. We often go for a long drive to participate in any seminar or conference. In that journey, it is must to ensure the comfort.

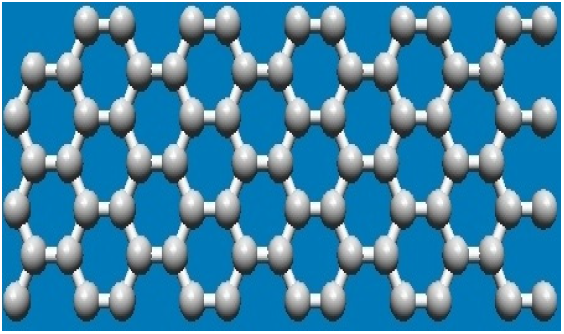

2. The piezoelectricity can be used for expansion and contraction of seat material but only piezoelectricity may not work rather 3D spacer fabrics are strongly recommended to be used. Warp knitted spacer fabric or specially designed spacer fabric can be introduced. Some research about woven spacer fabrics carried out in Bangladesh University of textiles showed void or space in the fabric where piezoelectric coil can be easily placed and can obtain the compression and expansion [6-9].

| Figure 3. Conceptual cross-section of a woven spacer fabric |

| Figure 4. Concept of woven double decker spacer fabric (more layers can be added by modifying the fabric design.) |

3. This 3D spacer fabric contains a lot of sunken areas where sensors can be placed and can show the expansion-compression properties of responsive car seat.

4. Expansion-compression would be produced by various ways:

- Warp knitted spacer fabric piezoelectric pile yarn/ connecting yarn.

- Foam integrated with some smart [10] materials like shape change materials.

5. A coil made of conductive yarn [11] may be placed in the sunken area of the fabric. When a sensor sense to this coil, this portion will be expanded. Stoppa and Chiolerio [11] reviewed this type of research. Kaushik et al. [2] have used some smart material [11-12] for getting this type of properties in fabric.

6. Metallic fibre woven spacer fabric can enhance the usability of the responsive car seat by modifying the following concept [13].

| Figure 5. Metallic fibre woven spacer fabric structures proposed- Left: front view, right: side view; HPF= High Performance fibre |

Concluding remarks

Reference

Check out these related articles:

1 thought on “Responsive Car Seats: Is It Too Good to Be True? | Common Car Seat Problems”