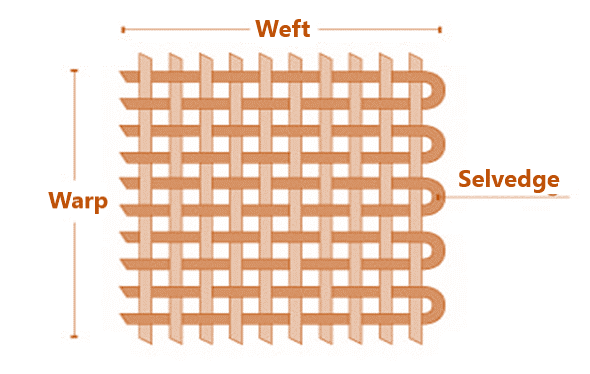

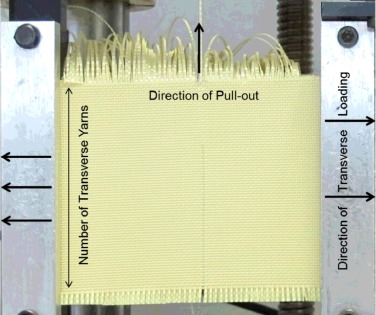

Yarn pull-out measurements reveal information on the interactions among the yarns of the fabrics, mainly on the friction between yarns. In the yarn pull-out method, the fabric is held by fixed jaws on both sides. A certain number of yarns in the form of fringe on the upper part of the fabric are formed and compressed into the upper movable jaw. The yarns held by the moving jaw are pulled in the upward direction and thus angle change is observed in the yarns (weft) located in the perpendicular direction to the yarns (warp) drawn. This method can be applied in any pulling device, but a special apparatus is needed to secure the fabric from both sides.

|

| Figure 1. Sample mounted on the Yarn pulling device |

The basic principle of this method, which is used to measure the shear deformation of woven fabrics, is to remove the yarns from the fabric specimen to form a 15 cm fringe and to pull a group containing a certain number of yarns from the middle of the fringe upwards from the fabric holding by the device. The number of yarns to be pulled varies between 1 and 5 and varies according to the type of fabric. Below figure shows the parameters of the yarn pull-out method. In the yarn pull-out method, the slip or shear angle (θ) is calculated geometrically using the fabric width (w) and the displacement (d) values observed by pulling. Shear resistance (G) is calculated from the relationship between tensile force (F), fabric width and shear stress (tanθ). The unit of weight (Wf) is expressed in g/m2 and the unit of specific shear resistance (Gsf) is expressed in Nm/g.

w1 = w2 = w/2………………(1)

𝜃1 = 𝜃2 = 𝜃 ……………………..(2)

tan𝜃 = d/(w/2) = 2d/w……………(3)

F/w = G x tan𝜃………………………….(4)

G = F/(w x tan𝜃)……………………………..(5)

Gsf = G/Wf………………………………………..(6)

In the study, the change in fabric curvature during measurements was omitted/ignored. The results obtained with this method were found to be similar to the results of simple shear test and cross-directional shear test. Shear deformation curves were similar to those obtained from the other two methods at the beginning, but the results were different as the force increased. This situation is explained by the shifting/sliding of threads over one another at the intersection points with the effect of increasing force. As the number of threads pulled increases, the measured shear resistance also increases. In the experiments with different sample sizes, it was found that the shear resistance value was higher as the sample size increased.

| Angle of applied force | Weft threads are perpendicular to the direction of force, warp threads are parallel to the direction of force. |

| Measuring principle | Removing the yarns from the fabric specimen to form a fringe and pulling a group of yarns from the middle of the fringe upwards in the fabric. Simple slip or shear is acceptable. |

| Effective measuring area (mm2) | 5×10, 5×20, 5×30, 15×10, 15×20, 15×30, 30×10, 30×20, 30×30 |

Texpedi.com

Check out these related articles: