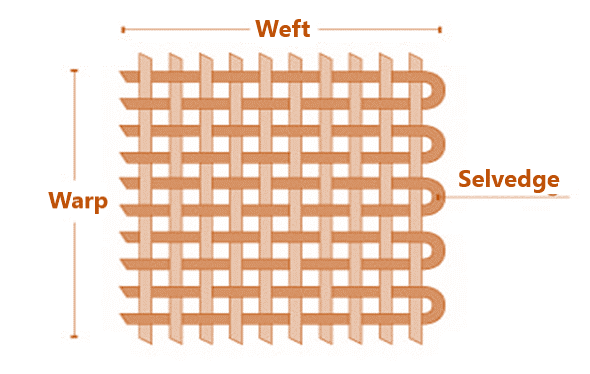

Woven fabrics | Weaving is a fabric forming technology where two sets of yarn namely warp thread (0°) and weft threads (90°) interlace orthogonally (interlace at right angle). Warp threads run along the process/looming direction (lengthwise), whereas weft yarns run along the loom width. Weft threads are also known as filling yarn. The weaving is one of the most popular fabric forming technologies. Some other fabric forming technologies are knitting, braiding, non-weaving. A woven fabric is a textile manufactured by weaving. Woven cloth is often woven on a loom with a large number of threads. In the bias orientation, woven fabric only extends diagonally. Woven fabric may be made on a variety of looms, from handlooms to power looms. Woven cloth may be used to make shirts, trousers, and jeans. Due to the usage of two or more threads, woven fabric is somewhat thick.

Characteristics of woven fabrics

- Woven fabrics are composed of two sets of yarns.

- Warp and weft yarns are interlaced at right angles.

- Warp yarns run along the length of the fabric and weft yarn runs across the width or perpendicular to the warp.

- Warp and weft yarns are kept together by weaving them over and under each other.

- Woven fabrics are more durable than other types of fabrics.

- Less stretch ability in the longitudinal and transverse direction. However, shows somewhat stretch ability diagonally.

Types of woven fabrics

1. Basic fabric structures

These are the basic woven fabric structures. For example: Plain fabrics, twill fabrics and satin or sateen fabrics. Satin fabrics are warp floated woven fabrics, whereas sateen fabrics are weft floated.

2. Advanced fabric structures

These types of woven fabrics can be of various two-dimensional and three-dimensional woven fabrics. Detail classification of the compound woven fabric structures are presented in figure 1.

| Classification of woven fabrics |

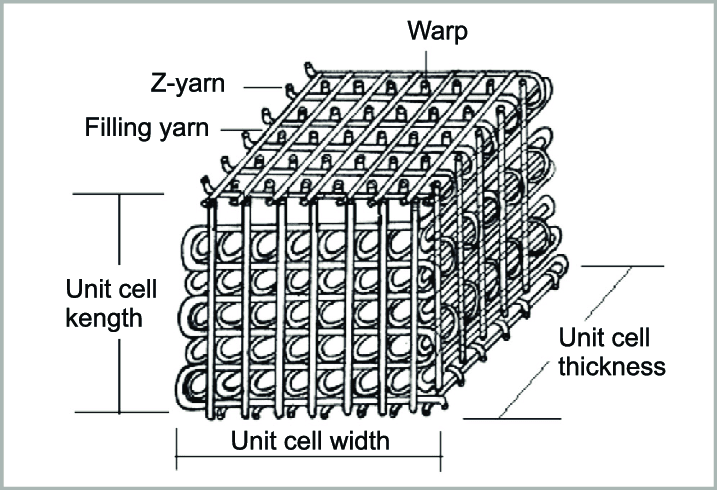

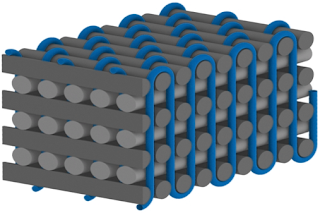

Textiles with three dimensions through thickness, known as X-direction, Y-direction, and Z-direction, are known as 3D woven fabrics. For 3D fabric constructions, yarn interlacing is usually done in three directions: longitudinal (X), cross (Y), and vertical (V) (Z). Three sets of strands, warp yarn, weft yarn, and z-yarn, are interlaced to create 3D woven fabric. The z-yarn reinforces the fabric by joining the warp and weft yarns through the thickness of the fabric during the development of 3D woven fabric. Three-dimensional (3D) angle-interlock woven textiles with high plasticity, mature technology, high efficiency, and cheap cost could be employed as high-properties composite preforms, and they have been widely used in the holistic processing of composite components. Some 3-D woven fabric schematics are shown below:

|

| Schematic view of the 3D orthogonal woven fabrics |

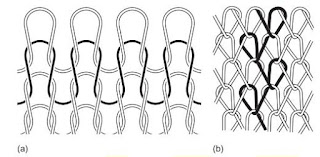

| Two kinds of woven structures: (a) three-dimensional orthogonality weave fabric, (b) three-dimensional interlock angle weave. |

|

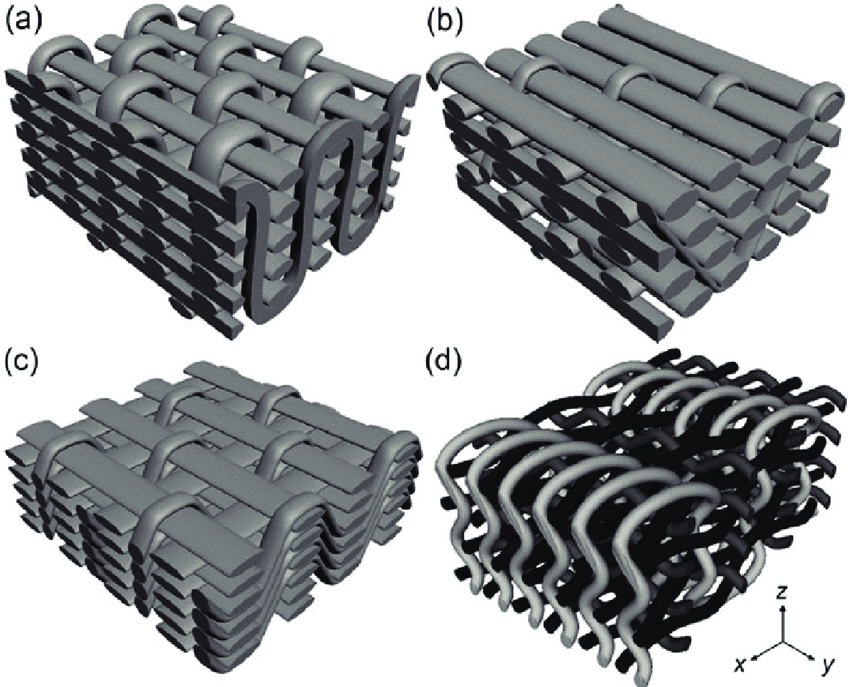

| 3D woven structures: (a) orthogonal, (b) through-the-thickness angle interlock, (c) layer-to-layer angle interlock, and (d) fully interlaced. |

Texpedi.com

Check out these related articles:

1 thought on “Various types of woven fabrics: A comprehensive discussion”