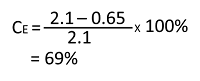

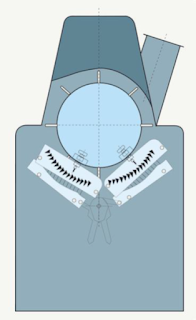

BlowRoom: Cotton fibre is compressed in a bale of 200 to 250 kg. This highly compressed cotton fibre need to be opened at first as a part of yarn manufacturing. And there is 1.5% to 7% trash in a cotton bale which is also needed to be removed before further processing. This process of opening & cleaning is known as blowroom process. Blowroom consists of a number of m/c used in succession to open & clean the cotton fibre to the required degree. 40% to 70% of the total trash is removed in this section.

Disadvantages of conventional blowroom line:

1. More gentle beating at free flight condition with less opening

2. Due to less opening, a very high degree of cleaning could not be accomplished

3. Less cleaning because opening and cleaning are not simultaneous actions

4. Less blender bin capacity

5. Less production because of start-stop operation

6. More space required

7. More number of machinery required

8. Overall cleaning efficiency is less

Advantages of modern blowroom:

1. High production

2. Reduction of human error

3. A large number of bales can be used for blending

4. Up to four assortments can be done

5. Beating by gripping i.e. controlled beating action

6. Smaller tuft size

7. PLC( Programmable logic controller) system used

8. Auto stop motion

9. Less worker required

10. Less space required

Texpedi.com

Check out these related articles: