Pilling is the formation of little balls of fibres (pills) on the surface of a fabric which is caused by abrasion in wear. It is the tendency of fibres to come loose from a fabric surface and form balled particles of fibre.

Causes of Pilling:

a. Due to wear and abrasion.

b. Due to rubbing action of fabric with particular parts of garments and body.

c. Due to softly twisted yarn.

d. Due to excess short fibres.

e. Due to migration of fibres from constituent yarn in fabric.

f. Due to protruding fibre/yarn hairiness.

g. Due to heat in case of thermoplastic fibres.

Reduction or Minimizing pilling:

a. By using high twisted yarn.

b. By brushing and cropping of the fabric surface to remove loose fibre ends.

c. By using the singeing process to reduce yarn hairiness, longer fibres.

d. By using the anti-pilling technique.

e. By special chemical treatment such as an adhesive, anti-rubbing agent.

f. By reducing migration of fibres by means of Air Jet spinning process.

g. By increasing inter-fibre friction.

h. By increasing the linear density of the fibre.

i. By using a high number of threads per unit length.

ICI BOX PILLING TEST:

1. For this test four specimens, each 5-inch x 5 inches are cut from the fabric.

2. A seam allowance of 12mm is marked on the back of each square. In two of the samples, the seam is marked parallel to the warp direction and in the other two parallel to the weft direction.

3. The samples are then folded face to face and a seam is sewn on the marked line.

4. This gives two specimens with the seam parallel to the warp and two with the seam parallel to the weft.

5. Each specimen is turned inside out and 6mm cut off each end of it thus removing any sewing distortion.

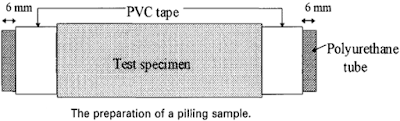

6. The fabric tubes made are then mounted on rubber tubes so that the length of the tube showing at each end is the same. Each of the loose ends is taped with poly (vinyl chloride) (PVC) tape so that 6mm of the rubber tube is left exposed as shown in Figure.

7. All four specimens are then placed in one pilling box.

8. The samples are then tumbled together in a cork-lined box as shown in Figure.

9. The usual number of revolutions used in the test is 18,000 which take 5 hrs.

Assessment

The specimens are removed from the tubes and viewed using oblique lighting. The samples are then given a rating of between 1 and 5 with the help of the descriptions in Table.

Texpedi.com

Check out these related articles:

1 thought on “Pilling। ICI Box Pilling Test”