Mixing:

If different grades of the same fibres are kept together, then it is called mixing.

Blending:

When different fibres of the same or different grades are kept together, then it is called blending.

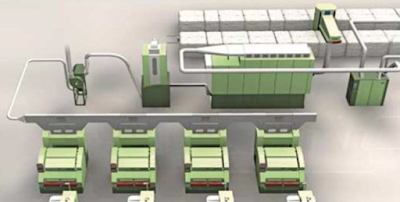

- Number of opening machines,

- Type of beater,

- Type of beating,

- Beater speed,

- Setting between feed roller and beater,

- The production rate of the individual machine,

- The production rate of the entire line,

- The thickness of the feed web,

- The density of the feed web,

- Fibre micronaire,

- Size of the flocks in the feed,

- Type of clothing of the beater,

- Point density of clothing,

- Type of grid and grid settings,

- Airflow through the grid,

- Position of the machine in the sequence,

- Amount of trash in the material,

- Type of trash in the material,

- Temp and relative humidity in the blow room department.

Texpedi.com

Check out these related articles:

1 thought on “Mixing and blending of cotton fibre in blow room.”