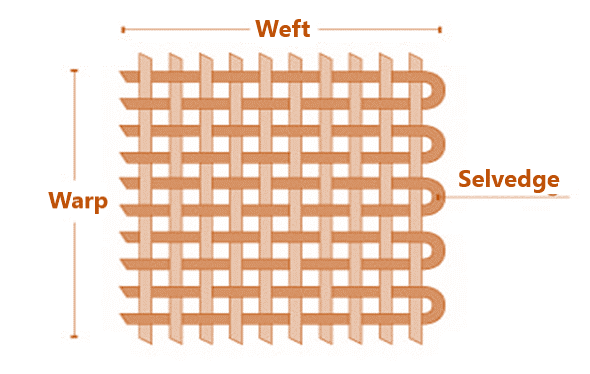

Weaving is a method of textile production in which two distinct sets of yarns or threads are interlaced at right angles to form a fabric. The longitudinal or lengthwise threads are called the warp and the lateral or width-wise threads are the weft or filling. Other methods of forming fabric are knitting, crocheting, felting, and braiding or plaiting.

Different Types of fabric weaves

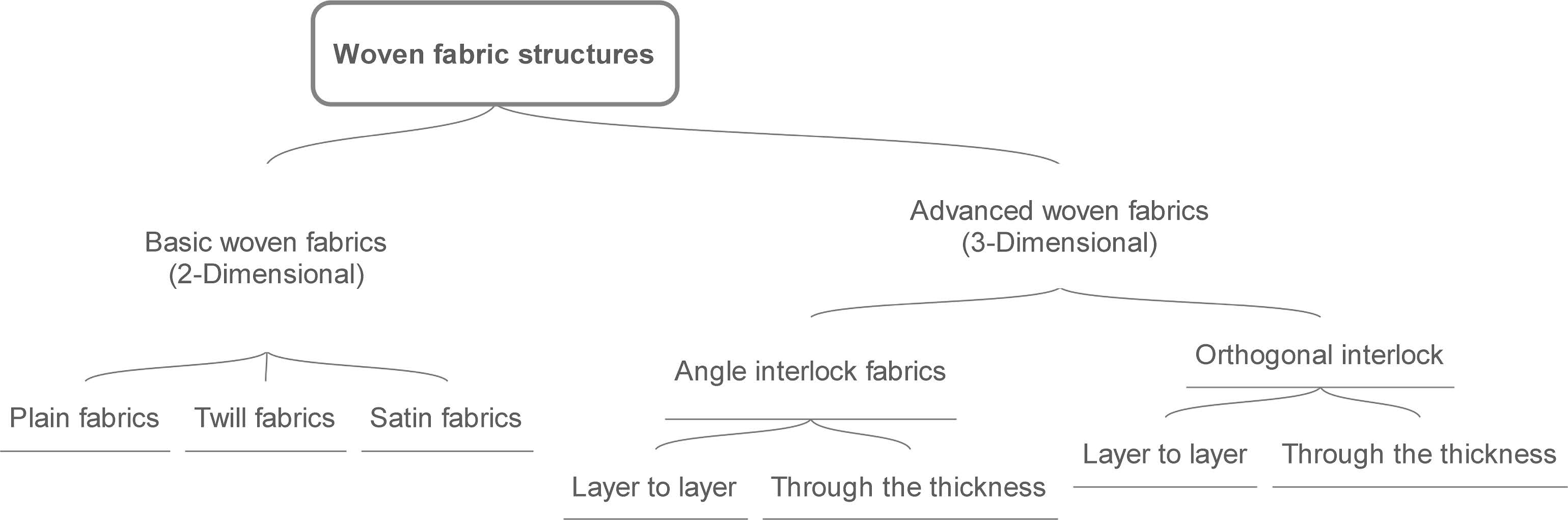

Though Plain, Twill and Satin are the basic weaves, there are a lot of commercial weave structure available as below-

| 1- Plain weave | 8- Leno weave | 15- Crepe weave |

| 2- Rib weave | 9- Oxford Weave | 16- Lappet weave |

| 3- Basket weave | 10- Bedford cord weave | 17- Tapestry Weave |

| 4- Twill Weave | 11- Waffle Weave | 18- Striped weaves |

| 5- Herringbone weave | 12- Pile weave | 19- Checquered weaves |

| 6- Satin weave | 13- Jacquard weave | 20- Double cloth weave |

| 7- Sateen weave | 14- Dobby weave |

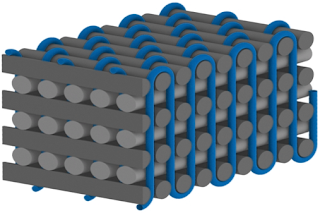

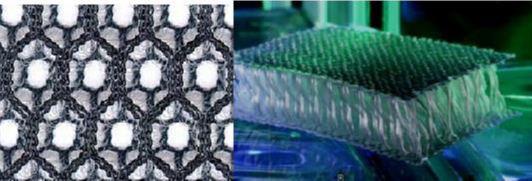

3D Woven Fabric: The fabric consisting of three different sets of yarns; warp yarns (y-yarn), weft yarns (x-yarn), and (z-yarn) while Z-yarn is placed in the through-thickness direction of the preform is known as 3D woven fabric. 3D fabrics can be produced via weaving, knitting, and non-weaving processes. The 3D fabric could be formed to near net shape with considerable thickness.

Advantages of 3D Woven Fabric in the composite industry:

👉3D woven fabrics are very useful in applications where the composite structure is subjected to out-of-plane loading, thanks to the extra strength provided by the z-yarn in the through-thickness dimension. Thus it can better resist delamination, which is the separation of layers due to out-of-plane forces.

👉3D woven fabrics have high formability, which means they can easily take the shape of the mold in case of complex composite designs.

👉3D woven fabrics have a highly porous structure, which decreases resin infusion time.

👉3D orthogonal woven fabrics have less or no yarn crimp (the difference in length of yarn, before and after weaving); therefore, mechanical properties of fibres are almost fully utilized in warp and weft directions. Thus, it could benefit from the maximum load-carrying capacity of high-performance fibres in these directions.

👉The shape of 3D woven fabrics can be tapered in all three directions during the weaving process, producing near net shape fabrics such as I-beams and stiffeners. This means that these preforms could be placed directly in the mold without any additional labour work.

Texpedi.com

Check out these related articles:

This is an informative article.Ikat Fabrics for sale online in india.it is helpful for us.Thanks for sharing it.

An Excellent article which needs to be highlighted.thanks for sharing an inspiring article. it is very interesting. SMS Non Woven Fabric Manufacturer in India